service manual ar-203e ar-203e x ar-m200 ar-m201 model ar-5420

service manual ar-203e ar-203e x ar-m200 ar-m201 model ar-5420

service manual ar-203e ar-203e x ar-m200 ar-m201 model ar-5420

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

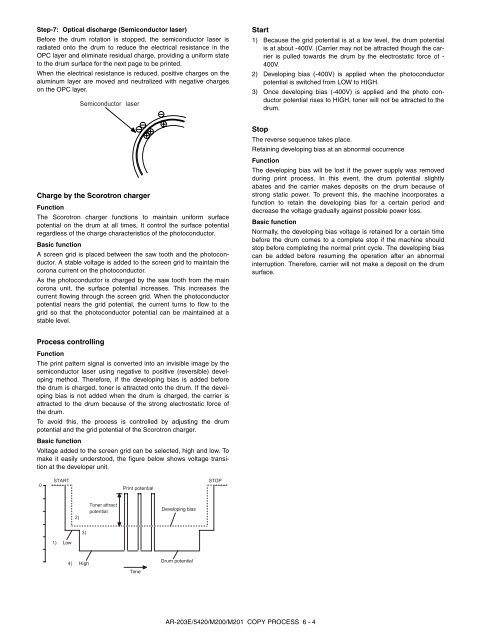

Step-7: Optical disch<strong>ar</strong>ge (Semiconductor laser)<br />

Before the drum rotation is stopped, the semiconductor laser is<br />

radiated onto the drum to reduce the electrical resistance in the<br />

OPC layer and eliminate residual ch<strong>ar</strong>ge, providing a uniform state<br />

to the drum surface for the next page to be printed.<br />

When the electrical resistance is reduced, positive ch<strong>ar</strong>ges on the<br />

aluminum layer <strong>ar</strong>e moved and neutralized with negative ch<strong>ar</strong>ges<br />

on the OPC layer.<br />

Ch<strong>ar</strong>ge by the Scorotron ch<strong>ar</strong>ger<br />

Function<br />

The Scorotron ch<strong>ar</strong>ger functions to maintain uniform surface<br />

potential on the drum at all times, It control the surface potential<br />

reg<strong>ar</strong>dless of the ch<strong>ar</strong>ge ch<strong>ar</strong>acteristics of the photoconductor.<br />

Basic function<br />

A screen grid is placed between the saw tooth and the photoconductor.<br />

A stable voltage is added to the screen grid to maintain the<br />

corona current on the photoconductor.<br />

As the photoconductor is ch<strong>ar</strong>ged by the saw tooth from the main<br />

corona unit, the surface potential increases. This increases the<br />

current flowing through the screen grid. When the photoconductor<br />

potential ne<strong>ar</strong>s the grid potential, the current turns to flow to the<br />

grid so that the photoconductor potential can be maintained at a<br />

stable level.<br />

Process controlling<br />

Function<br />

The print pattern signal is converted into an invisible image by the<br />

semiconductor laser using negative to positive (reversible) developing<br />

method. Therefore, if the developing bias is added before<br />

the drum is ch<strong>ar</strong>ged, toner is attracted onto the drum. If the developing<br />

bias is not added when the drum is ch<strong>ar</strong>ged, the c<strong>ar</strong>rier is<br />

attracted to the drum because of the strong electrostatic force of<br />

the drum.<br />

To avoid this, the process is controlled by adjusting the drum<br />

potential and the grid potential of the Scorotron ch<strong>ar</strong>ger.<br />

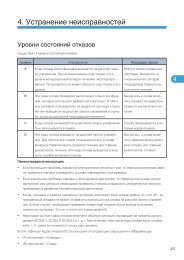

Basic function<br />

Voltage added to the screen grid can be selected, high and low. To<br />

make it easily understood, the figure below shows voltage transition<br />

at the developer unit.<br />

0<br />

Semiconductor laser<br />

START STOP<br />

Print potential<br />

1) Low<br />

2)<br />

3)<br />

4) High<br />

Toner attract<br />

potential<br />

Time<br />

Developing bias<br />

Drum potential<br />

AR-203E/<strong>5420</strong>/M200/M201 COPY PROCESS 6 - 4<br />

St<strong>ar</strong>t<br />

1) Because the grid potential is at a low level, the drum potential<br />

is at about -400V. (C<strong>ar</strong>rier may not be attracted though the c<strong>ar</strong>rier<br />

is pulled tow<strong>ar</strong>ds the drum by the electrostatic force of -<br />

400V.<br />

2) Developing bias (-400V) is applied when the photoconductor<br />

potential is switched from LOW to HIGH.<br />

3) Once developing bias (-400V) is applied and the photo conductor<br />

potential rises to HIGH, toner will not be attracted to the<br />

drum.<br />

Stop<br />

The reverse sequence takes place.<br />

Retaining developing bias at an abnormal occurrence<br />

Function<br />

The developing bias will be lost if the power supply was removed<br />

during print process. In this event, the drum potential slightly<br />

abates and the c<strong>ar</strong>rier makes deposits on the drum because of<br />

strong static power. To prevent this, the machine incorporates a<br />

function to retain the developing bias for a certain period and<br />

decrease the voltage gradually against possible power loss.<br />

Basic function<br />

Normally, the developing bias voltage is retained for a certain time<br />

before the drum comes to a complete stop if the machine should<br />

stop before completing the normal print cycle. The developing bias<br />

can be added before resuming the operation after an abnormal<br />

interruption. Therefore, c<strong>ar</strong>rier will not make a deposit on the drum<br />

surface.