Navy Electricity and Electronics Training Series - Historic Naval ...

Navy Electricity and Electronics Training Series - Historic Naval ...

Navy Electricity and Electronics Training Series - Historic Naval ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

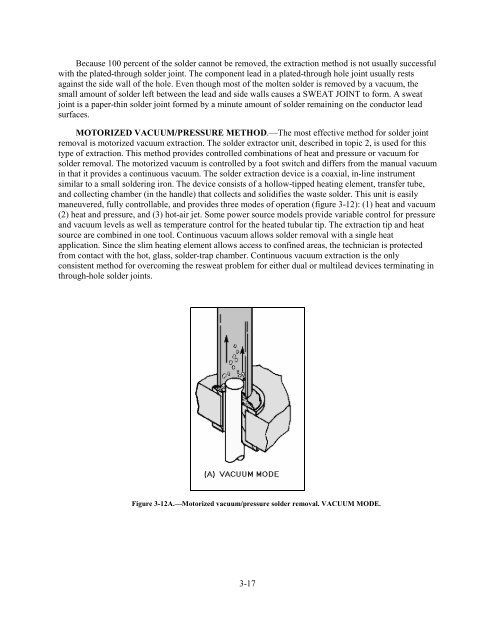

Because 100 percent of the solder cannot be removed, the extraction method is not usually successfulwith the plated-through solder joint. The component lead in a plated-through hole joint usually restsagainst the side wall of the hole. Even though most of the molten solder is removed by a vacuum, thesmall amount of solder left between the lead <strong>and</strong> side walls causes a SWEAT JOINT to form. A sweatjoint is a paper-thin solder joint formed by a minute amount of solder remaining on the conductor leadsurfaces.MOTORIZED VACUUM/PRESSURE METHOD.—The most effective method for solder jointremoval is motorized vacuum extraction. The solder extractor unit, described in topic 2, is used for thistype of extraction. This method provides controlled combinations of heat <strong>and</strong> pressure or vacuum forsolder removal. The motorized vacuum is controlled by a foot switch <strong>and</strong> differs from the manual vacuumin that it provides a continuous vacuum. The solder extraction device is a coaxial, in-line instrumentsimilar to a small soldering iron. The device consists of a hollow-tipped heating element, transfer tube,<strong>and</strong> collecting chamber (in the h<strong>and</strong>le) that collects <strong>and</strong> solidifies the waste solder. This unit is easilymaneuvered, fully controllable, <strong>and</strong> provides three modes of operation (figure 3-12): (1) heat <strong>and</strong> vacuum(2) heat <strong>and</strong> pressure, <strong>and</strong> (3) hot-air jet. Some power source models provide variable control for pressure<strong>and</strong> vacuum levels as well as temperature control for the heated tubular tip. The extraction tip <strong>and</strong> heatsource are combined in one tool. Continuous vacuum allows solder removal with a single heatapplication. Since the slim heating element allows access to confined areas, the technician is protectedfrom contact with the hot, glass, solder-trap chamber. Continuous vacuum extraction is the onlyconsistent method for overcoming the resweat problem for either dual or multilead devices terminating inthrough-hole solder joints.Figure 3-12A.—Motorized vacuum/pressure solder removal. VACUUM MODE.3-17