- Page 1 and 2:

NONRESIDENTTRAININGCOURSESEPTEMBER

- Page 3 and 4:

PREFACEBy enrolling in this self-st

- Page 5:

TABLE OF CONTENTSCHAPTERPAGE1. Micr

- Page 8 and 9:

Module 11, Microwave Principles, ex

- Page 10 and 11:

INSTRUCTIONS FOR TAKING THE COURSEA

- Page 12 and 13:

THIS PAGE LEFT BLANK INTENTIONALLY.

- Page 15 and 16:

CHAPTER 1MICROELECTRONICSLEARNING O

- Page 17 and 18:

VACUUM-TUBE EQUIPMENTVacuum tubes w

- Page 19 and 20:

SOLID-STATE DEVICESNow would be a g

- Page 21 and 22:

FILM INTEGRATED CIRCUITS are broken

- Page 23 and 24:

Development of a microelectronic de

- Page 25 and 26:

Figure 1-9.—Crystal furnace.The c

- Page 27 and 28:

Figure 1-12.—Planar-diffused tran

- Page 29 and 30:

Figure 1-14.—Vacuum evaporation o

- Page 31 and 32:

Figure 1-17.—Cathode-sputtering m

- Page 33 and 34:

Q23. How do the two types of monoli

- Page 35 and 36:

Figure 1-21A.—TO-5 mounting PLUG-

- Page 37 and 38:

Dual Inline PackageThe dual inline

- Page 39 and 40:

wafer, as shown in figure 1-27. Thi

- Page 41 and 42:

Figure 1-29.—J-K flip-flop discre

- Page 43 and 44:

Figure 1-31.—Lead numbering for a

- Page 45 and 46:

Figure 1-34.—Manufacturer's Data

- Page 47:

comparison to the distance between

- Page 50 and 51:

LEVEL III.—Drawers or pull-out ch

- Page 52 and 53:

Conductors located several layers b

- Page 54 and 55:

Figure 1-43A.—Evolution of modula

- Page 56 and 57:

ENVIRONMENTAL CONSIDERATIONSThe env

- Page 58 and 59:

SUMMARYThis topic has presented inf

- Page 60 and 61:

Rapid development has resulted in i

- Page 62 and 63:

Large DIPs are being used to packag

- Page 64 and 65:

MINIATURE ELECTRONICS are card asse

- Page 66 and 67:

Three methods of interconnecting ci

- Page 68 and 69:

ANSWERS TO QUESTIONS Q1. THROUGH Q5

- Page 70 and 71:

A43. Conventional printed circuit b

- Page 72 and 73:

Upon satisfactory completion of a 2

- Page 74 and 75:

One such improvement in system test

- Page 76 and 77:

those that should be observed when

- Page 78 and 79:

Figure 2-2.—Low voltage Handpiece

- Page 80 and 81:

Figure 2-6.—Rotary-drive machine

- Page 82 and 83:

Figure 2-9.—Pana Vise.HAND TOOLSF

- Page 84 and 85:

Figure 2-10a.—Pliers.TweezersView

- Page 86 and 87:

Even though all the items are not u

- Page 88 and 89:

Figure 2-14.—Stereoscopic zoom mi

- Page 90 and 91:

other than eutectic, go through a p

- Page 92 and 93: A1. Chief of Naval Operations (CNO)

- Page 94 and 95: CAUTIONTHIS SECTION IS NOT, IN ANY

- Page 96 and 97: The coating material can best be id

- Page 98 and 99: Figure 3-3.—Rotary tool conformal

- Page 100 and 101: Figure 3-4A.—Eyelets (interfacial

- Page 102 and 103: Figure 3-5B.—Clinched leads. SEMI

- Page 104 and 105: Figure 3-8A.—Terminals. PIN AND T

- Page 106 and 107: Figure 3-8E.—Terminals. SOLDER CU

- Page 108 and 109: Figure 3-10.—Solder wicking.This

- Page 110 and 111: Figure 3-12B.—Motorized vacuum/pr

- Page 112 and 113: INSTALLATION AND SOLDERING OF PRINT

- Page 114 and 115: Figure 3-15.—Component arrangemen

- Page 116 and 117: Figure 3-16.—Thermal shunt.APPLIC

- Page 118 and 119: Removal of Plug-In DIPsTo remove pl

- Page 120 and 121: Figure 3-19.—TO mounting techniqu

- Page 122 and 123: Figure 3-21.—Flat pack in protect

- Page 124 and 125: Figure 3-23.—Pcb conductor damage

- Page 126 and 127: REPAIRING DELAMINATED CONDUCTORS.

- Page 128 and 129: 5. The repair is completed using th

- Page 130 and 131: SAFETYSafety is a subject of utmost

- Page 132 and 133: OBJECT OR PROCESSWORK SURFACESFLOOR

- Page 134 and 135: 8. When moving an ESDS device or as

- Page 136 and 137: Power ToolsHazards associated with

- Page 138 and 139: dispensers will prevent many accide

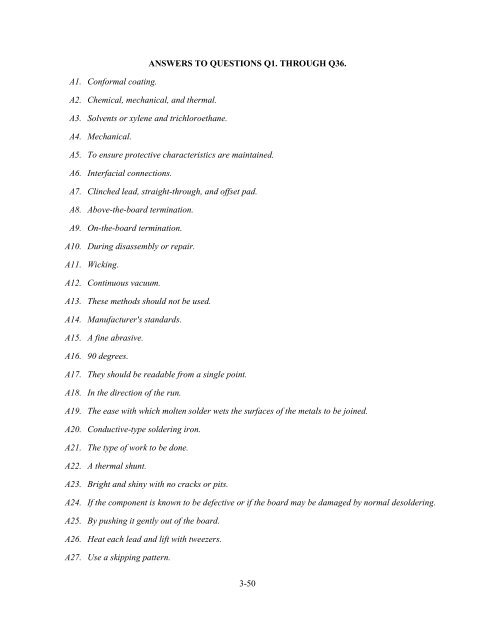

- Page 140 and 141: A GOOD SOLDER JOINT is bright and s

- Page 145 and 146: APPENDIX IGLOSSARYALLOWANCE PARTS L

- Page 147 and 148: MODULAR PACKAGING—Circuit assembl

- Page 149: APPENDIX IIREFERENCE LISTCHAPTER ON

- Page 152 and 153: Microelectronics—Continuedpackagi

- Page 155: Assignment QuestionsInformation: Th

- Page 158 and 159: 1-7. Which of the following charact

- Page 160 and 161: 1-24. Vacuum evaporation and cathod

- Page 162 and 163: ___________________________________

- Page 164 and 165: 1-49. Ground planes and shielding a

- Page 166 and 167: 1-65. Which of the following types

- Page 168 and 169: ASSIGNMENT 2Textbook assignment: Ch

- Page 170 and 171: 2-20. Turret, fork, and hook termin

- Page 172 and 173: 2-39. Component leads may be clippe

- Page 174 and 175: 2-52. To ensure a good mechanical b