Navy Electricity and Electronics Training Series - Historic Naval ...

Navy Electricity and Electronics Training Series - Historic Naval ...

Navy Electricity and Electronics Training Series - Historic Naval ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

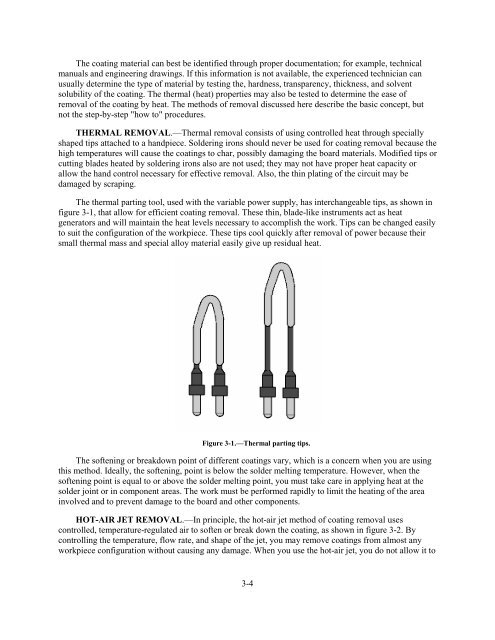

The coating material can best be identified through proper documentation; for example, technicalmanuals <strong>and</strong> engineering drawings. If this information is not available, the experienced technician canusually determine the type of material by testing the, hardness, transparency, thickness, <strong>and</strong> solventsolubility of the coating. The thermal (heat) properties may also be tested to determine the ease ofremoval of the coating by heat. The methods of removal discussed here describe the basic concept, butnot the step-by-step "how to" procedures.THERMAL REMOVAL.—Thermal removal consists of using controlled heat through speciallyshaped tips attached to a h<strong>and</strong>piece. Soldering irons should never be used for coating removal because thehigh temperatures will cause the coatings to char, possibly damaging the board materials. Modified tips orcutting blades heated by soldering irons also are not used; they may not have proper heat capacity orallow the h<strong>and</strong> control necessary for effective removal. Also, the thin plating of the circuit may bedamaged by scraping.The thermal parting tool, used with the variable power supply, has interchangeable tips, as shown infigure 3-1, that allow for efficient coating removal. These thin, blade-like instruments act as heatgenerators <strong>and</strong> will maintain the heat levels necessary to accomplish the work. Tips can be changed easilyto suit the configuration of the workpiece. These tips cool quickly after removal of power because theirsmall thermal mass <strong>and</strong> special alloy material easily give up residual heat.Figure 3-1.—Thermal parting tips.The softening or breakdown point of different coatings vary, which is a concern when you are usingthis method. Ideally, the softening, point is below the solder melting temperature. However, when thesoftening point is equal to or above the solder melting point, you must take care in applying heat at thesolder joint or in component areas. The work must be performed rapidly to limit the heating of the areainvolved <strong>and</strong> to prevent damage to the board <strong>and</strong> other components.HOT-AIR JET REMOVAL.—In principle, the hot-air jet method of coating removal usescontrolled, temperature-regulated air to soften or break down the coating, as shown in figure 3-2. Bycontrolling the temperature, flow rate, <strong>and</strong> shape of the jet, you may remove coatings from almost anyworkpiece configuration without causing any damage. When you use the hot-air jet, you do not allow it to3-4