Navy Electricity and Electronics Training Series - Historic Naval ...

Navy Electricity and Electronics Training Series - Historic Naval ...

Navy Electricity and Electronics Training Series - Historic Naval ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

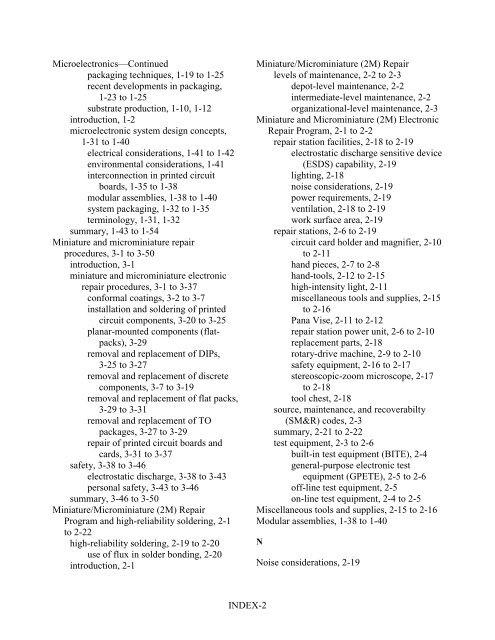

Microelectronics—Continuedpackaging techniques, 1-19 to 1-25recent developments in packaging,1-23 to 1-25substrate production, 1-10, 1-12introduction, 1-2microelectronic system design concepts,1-31 to 1-40electrical considerations, 1-41 to 1-42environmental considerations, 1-41interconnection in printed circuitboards, 1-35 to 1-38modular assemblies, 1-38 to 1-40system packaging, 1-32 to 1-35terminology, 1-31, 1-32summary, 1-43 to 1-54Miniature <strong>and</strong> microminiature repairprocedures, 3-1 to 3-50introduction, 3-1miniature <strong>and</strong> microminiature electronicrepair procedures, 3-1 to 3-37conformal coatings, 3-2 to 3-7installation <strong>and</strong> soldering of printedcircuit components, 3-20 to 3-25planar-mounted components (flatpacks),3-29removal <strong>and</strong> replacement of DIPs,3-25 to 3-27removal <strong>and</strong> replacement of discretecomponents, 3-7 to 3-19removal <strong>and</strong> replacement of flat packs,3-29 to 3-31removal <strong>and</strong> replacement of TOpackages, 3-27 to 3-29repair of printed circuit boards <strong>and</strong>cards, 3-31 to 3-37safety, 3-38 to 3-46electrostatic discharge, 3-38 to 3-43personal safety, 3-43 to 3-46summary, 3-46 to 3-50Miniature/Microminiature (2M) RepairProgram <strong>and</strong> high-reliability soldering, 2-1to 2-22high-reliability soldering, 2-19 to 2-20use of flux in solder bonding, 2-20introduction, 2-1Miniature/Microminiature (2M) Repairlevels of maintenance, 2-2 to 2-3depot-level maintenance, 2-2intermediate-level maintenance, 2-2organizational-level maintenance, 2-3Miniature <strong>and</strong> Microminiature (2M) ElectronicRepair Program, 2-1 to 2-2repair station facilities, 2-18 to 2-19electrostatic discharge sensitive device(ESDS) capability, 2-19lighting, 2-18noise considerations, 2-19power requirements, 2-19ventilation, 2-18 to 2-19work surface area, 2-19repair stations, 2-6 to 2-19circuit card holder <strong>and</strong> magnifier, 2-10to 2-11h<strong>and</strong> pieces, 2-7 to 2-8h<strong>and</strong>-tools, 2-12 to 2-15high-intensity light, 2-11miscellaneous tools <strong>and</strong> supplies, 2-15to 2-16Pana Vise, 2-11 to 2-12repair station power unit, 2-6 to 2-10replacement parts, 2-18rotary-drive machine, 2-9 to 2-10safety equipment, 2-16 to 2-17stereoscopic-zoom microscope, 2-17to 2-18tool chest, 2-18source, maintenance, <strong>and</strong> recoverabilty(SM&R) codes, 2-3summary, 2-21 to 2-22test equipment, 2-3 to 2-6built-in test equipment (BITE), 2-4general-purpose electronic testequipment (GPETE), 2-5 to 2-6off-line test equipment, 2-5on-line test equipment, 2-4 to 2-5Miscellaneous tools <strong>and</strong> supplies, 2-15 to 2-16Modular assemblies, 1-38 to 1-40NNoise considerations, 2-19INDEX-2