Phase-field modeling of diffusion controlled phase ... - KTH Mechanics

Phase-field modeling of diffusion controlled phase ... - KTH Mechanics

Phase-field modeling of diffusion controlled phase ... - KTH Mechanics

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

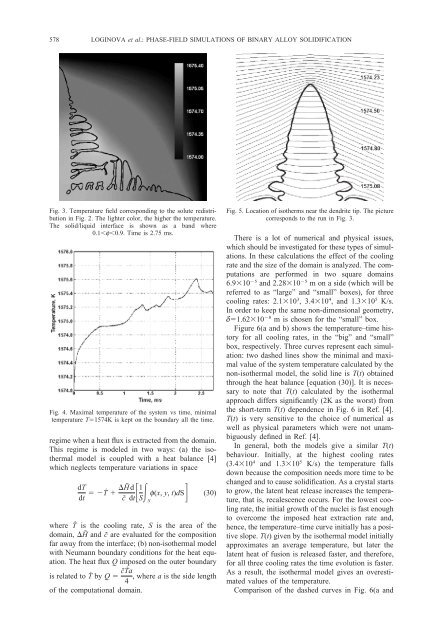

578 LOGINOVA et al.: PHASE-FIELD SIMULATIONS OF BINARY ALLOY SOLIDIFICATIONFig. 3. Temperature <strong>field</strong> corresponding to the solute redistributionin Fig. 2. The lighter color, the higher the temperature.The solid/liquid interface is shown as a band where0.1f0.9. Time is 2.75 ms.Fig. 4. Maximal temperature <strong>of</strong> the system vs time, minimaltemperature T1574K is kept on the boundary all the time.regime when a heat flux is extracted from the domain.This regime is modeled in two ways: (a) the isothermalmodel is coupled with a heat balance [4]which neglects temperature variations in spacedTdtṪ H˜c˜ddt 1 f(x, y, t)dS (30)SSwhere Ṫ is the cooling rate, S is the area <strong>of</strong> thedomain, H˜ and c˜ are evaluated for the compositionfar away from the interface; (b) non-isothermal modelwith Neumann boundary conditions for the heat equation.The heat flux Q imposed on the outer boundaryis related to Ṫ by Q c˜Ṫa , where a is the side length4<strong>of</strong> the computational domain.Fig. 5. Location <strong>of</strong> isotherms near the dendrite tip. The picturecorresponds to the run in Fig. 3.There is a lot <strong>of</strong> numerical and physical issues,which should be investigated for these types <strong>of</strong> simulations.In these calculations the effect <strong>of</strong> the coolingrate and the size <strong>of</strong> the domain is analyzed. The computationsare performed in two square domains6.910 5 and 2.2810 5 m on a side (which will bereferred to as “large” and “small” boxes), for threecooling rates: 2.110 3 , 3.410 4 , and 1.310 5 K/s.In order to keep the same non-dimensional geometry,d1.6210 8 m is chosen for the “small” box.Figure 6(a and b) shows the temperature–time historyfor all cooling rates, in the “big” and “small”box, respectively. Three curves represent each simulation:two dashed lines show the minimal and maximalvalue <strong>of</strong> the system temperature calculated by thenon-isothermal model, the solid line is T(t) obtainedthrough the heat balance [equation (30)]. It is necessaryto note that T(t) calculated by the isothermalapproach differs significantly (2K as the worst) fromthe short-term T(t) dependence in Fig. 6 in Ref. [4].T(t) is very sensitive to the choice <strong>of</strong> numerical aswell as physical parameters which were not unambiguouslydefined in Ref. [4].In general, both the models give a similar T(t)behaviour. Initially, at the highest cooling rates(3.410 4 and 1.310 5 K/s) the temperature fallsdown because the composition needs more time to bechanged and to cause solidification. As a crystal startsto grow, the latent heat release increases the temperature,that is, recalescence occurs. For the lowest coolingrate, the initial growth <strong>of</strong> the nuclei is fast enoughto overcome the imposed heat extraction rate and,hence, the temperature–time curve initially has a positiveslope. T(t) given by the isothermal model initiallyapproximates an average temperature, but later thelatent heat <strong>of</strong> fusion is released faster, and therefore,for all three cooling rates the time evolution is faster.As a result, the isothermal model gives an overestimatedvalues <strong>of</strong> the temperature.Comparison <strong>of</strong> the dashed curves in Fig. 6(a and