Phase-field modeling of diffusion controlled phase ... - KTH Mechanics

Phase-field modeling of diffusion controlled phase ... - KTH Mechanics

Phase-field modeling of diffusion controlled phase ... - KTH Mechanics

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

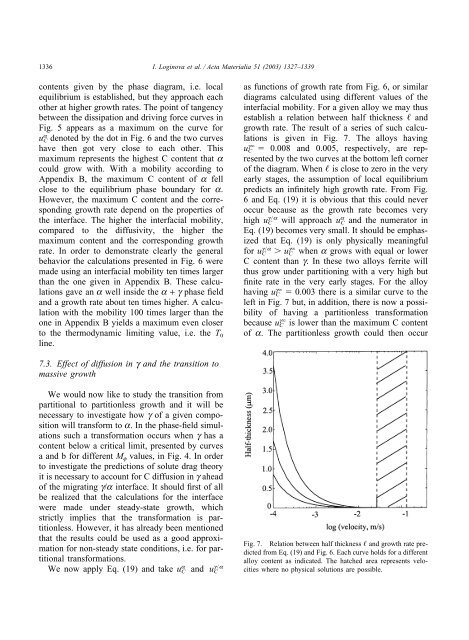

1336 I. Loginova et al. / Acta Materialia 51 (2003) 1327–1339contents given by the <strong>phase</strong> diagram, i.e. localequilibrium is established, but they approach eachother at higher growth rates. The point <strong>of</strong> tangencybetween the dissipation and driving force curves inFig. 5 appears as a maximum on the curve foru a C denoted by the dot in Fig. 6 and the two curveshave then got very close to each other. Thismaximum represents the highest C content that acould grow with. With a mobility according toAppendix B, the maximum C content <strong>of</strong> a fellclose to the equilibrium <strong>phase</strong> boundary for a.However, the maximum C content and the correspondinggrowth rate depend on the properties <strong>of</strong>the interface. The higher the interfacial mobility,compared to the diffusivity, the higher themaximum content and the corresponding growthrate. In order to demonstrate clearly the generalbehavior the calculations presented in Fig. 6 weremade using an interfacial mobility ten times largerthan the one given in Appendix B. These calculationsgave an a well inside the a + g <strong>phase</strong> <strong>field</strong>and a growth rate about ten times higher. A calculationwith the mobility 100 times larger than theone in Appendix B yields a maximum even closerto the thermodynamic limiting value, i.e. the T 0line.as functions <strong>of</strong> growth rate from Fig. 6, or similardiagrams calculated using different values <strong>of</strong> theinterfacial mobility. For a given alloy we may thusestablish a relation between half thickness andgrowth rate. The result <strong>of</strong> a series <strong>of</strong> such calculationsis given in Fig. 7. The alloys havinguCg 0.008 and 0.005, respectively, are representedby the two curves at the bottom left corner<strong>of</strong> the diagram. When is close to zero in the veryearly stages, the assumption <strong>of</strong> local equilibriumpredicts an infinitely high growth rate. From Fig.6 and Eq. (19) it is obvious that this could neveroccur because as the growth rate becomes veryhigh u g C/a will approach u a C and the numerator inEq. (19) becomes very small. It should be emphasizedthat Eq. (19) is only physically meaningfulfor u g/aC uCg when a grows with equal or lowerC content than g. In these two alloys ferrite willthus grow under partitioning with a very high butfinite rate in the very early stages. For the alloyhaving u gC 0.003 there is a similar curve to theleft in Fig. 7 but, in addition, there is now a possibility<strong>of</strong> having a partitionless transformationbecause u gC is lower than the maximum C content<strong>of</strong> a. The partitionless growth could then occur7.3. Effect <strong>of</strong> <strong>diffusion</strong> in g and the transition tomassive growthWe would now like to study the transition frompartitional to partitionless growth and it will benecessary to investigate how g <strong>of</strong> a given compositionwill transform to a. In the <strong>phase</strong>-<strong>field</strong> simulationssuch a transformation occurs when g has acontent below a critical limit, presented by curvesa and b for different M f values, in Fig. 4. In orderto investigate the predictions <strong>of</strong> solute drag theoryit is necessary to account for C <strong>diffusion</strong> in g ahead<strong>of</strong> the migrating g/a interface. It should first <strong>of</strong> allbe realized that the calculations for the interfacewere made under steady-state growth, whichstrictly implies that the transformation is partitionless.However, it has already been mentionedthat the results could be used as a good approximationfor non-steady state conditions, i.e. for partitionaltransformations.We now apply Eq. (19) and take u a Cand u g/aCFig. 7. Relation between half thickness and growth rate predictedfrom Eq. (19) and Fig. 6. Each curve holds for a differentalloy content as indicated. The hatched area represents velocitieswhere no physical solutions are possible.