KVPT’s Patan Darbar Earthquake Response Campaign - Work to Date - September 2016

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

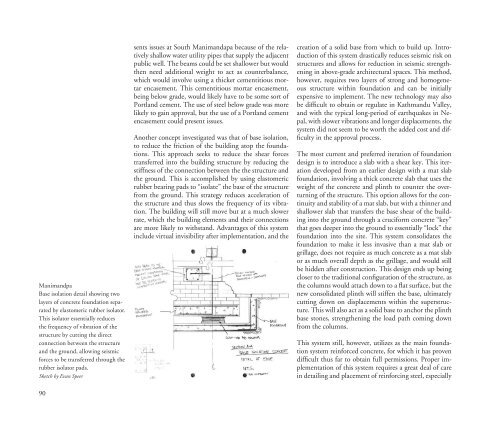

Manimandpa<br />

Base isolation detail showing two<br />

layers of concrete foundation separated<br />

by elas<strong>to</strong>meric rubber isola<strong>to</strong>r.<br />

This isola<strong>to</strong>r essentially reduces<br />

the frequency of vibration of the<br />

structure by cutting the direct<br />

connection between the structure<br />

and the ground, allowing seismic<br />

forces <strong>to</strong> be transferred through the<br />

rubber isola<strong>to</strong>r pads.<br />

Sketch by Evan Speer<br />

sents issues at South Manimandapa because of the relatively<br />

shallow water utility pipes that supply the adjacent<br />

public well. The beams could be set shallower but would<br />

then need additional weight <strong>to</strong> act as counterbalance,<br />

which would involve using a thicker cementitious mortar<br />

encasement. This cementitious mortar encasement,<br />

being below grade, would likely have <strong>to</strong> be some sort of<br />

Portland cement. The use of steel below grade was more<br />

likely <strong>to</strong> gain approval, but the use of a Portland cement<br />

encasement could present issues.<br />

Another concept investigated was that of base isolation,<br />

<strong>to</strong> reduce the friction of the building a<strong>to</strong>p the foundations.<br />

This approach seeks <strong>to</strong> reduce the shear forces<br />

transferred in<strong>to</strong> the building structure by reducing the<br />

stiffness of the connection between the the structure and<br />

the ground. This is accomplished by using elas<strong>to</strong>meric<br />

rubber bearing pads <strong>to</strong> “isolate” the base of the structure<br />

from the ground. This strategy reduces acceleration of<br />

the structure and thus slows the frequency of its vibration.<br />

The building will still move but at a much slower<br />

rate, which the building elements and their connections<br />

are more likely <strong>to</strong> withstand. Advantages of this system<br />

include virtual invisibility after implementation, and the<br />

creation of a solid base from which <strong>to</strong> build up. Introduction<br />

of this system drastically reduces seismic risk on<br />

structures and allows for reduction in seismic strengthening<br />

in above-grade architectural spaces. This method,<br />

however, requires two layers of strong and homogeneous<br />

structure within foundation and can be initially<br />

expensive <strong>to</strong> implement. The new technology may also<br />

be difficult <strong>to</strong> obtain or regulate in Kathmandu Valley,<br />

and with the typical long-period of earthquakes in Nepal,<br />

with slower vibrations and longer displacements, the<br />

system did not seem <strong>to</strong> be worth the added cost and difficulty<br />

in the approval process.<br />

The most current and preferred iteration of foundation<br />

design is <strong>to</strong> introduce a slab with a shear key. This iteration<br />

developed from an earlier design with a mat slab<br />

foundation, involving a thick concrete slab that uses the<br />

weight of the concrete and plinth <strong>to</strong> counter the overturning<br />

of the structure. This option allows for the continuity<br />

and stability of a mat slab, but with a thinner and<br />

shallower slab that transfers the base shear of the building<br />

in<strong>to</strong> the ground through a cruciform concrete “key”<br />

that goes deeper in<strong>to</strong> the ground <strong>to</strong> essentially “lock” the<br />

foundation in<strong>to</strong> the site. This system consolidates the<br />

foundation <strong>to</strong> make it less invasive than a mat slab or<br />

grillage, does not require as much concrete as a mat slab<br />

or as much overall depth as the grillage, and would still<br />

be hidden after construction. This design ends up being<br />

closer <strong>to</strong> the traditional configuration of the structure, as<br />

the columns would attach down <strong>to</strong> a flat surface, but the<br />

new consolidated plinth will stiffen the base, ultimately<br />

cutting down on displacements within the superstructure.<br />

This will also act as a solid base <strong>to</strong> anchor the plinth<br />

base s<strong>to</strong>nes, strengthening the load path coming down<br />

from the columns.<br />

This system still, however, utilizes as the main foundation<br />

system reinforced concrete, for which it has proven<br />

difficult thus far <strong>to</strong> obtain full permissions. Proper implementation<br />

of this system requires a great deal of care<br />

in detailing and placement of reinforcing steel, especially<br />

90