UWE Bristol Engineering showcase 2015

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Introduction<br />

Although aeroplanes were made to<br />

spend most of time flying, one of the<br />

most critical item to maintain their<br />

security plays its work on land: the tires.<br />

Though tires have an important role,<br />

they are frequently neglected and<br />

forgotten which can end on tragedies.<br />

Tires are critical items for the security<br />

for several reasons: support the weight<br />

of the aeroplane on the ground, absorb<br />

part of the impact between aircraft and<br />

airstrip with intense accelerations and<br />

decelerations and large variations of<br />

temperature.<br />

Thus, tires demand a special attention<br />

on their maintenance, inspection and<br />

storage in order to prevent damages and<br />

optimize their life.<br />

Problems caused by poor storage<br />

Many problems can be caused by<br />

inadequate storage, such as: tread<br />

separation, groove cracking, rib<br />

undercutting, ozone or weather<br />

checking/cracking, sidewall separation,<br />

etc.<br />

A tread separation can be seen below:<br />

Osvaldo Akiyoshi Kobayashi<br />

BEng Mechanical <strong>Engineering</strong><br />

Project and Design of Storage Rack for Aircraft Tires<br />

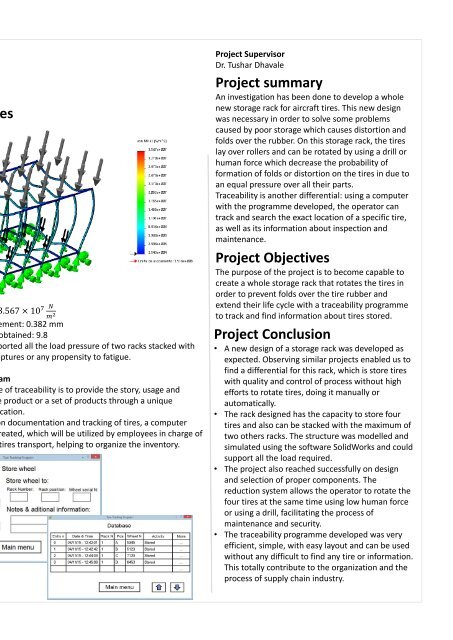

Design, Modelling and Simulation<br />

For the rack design a concept with capacity<br />

to store four tires and be stackable was<br />

developed.<br />

Two types of racks were designed according<br />

to the range of tires, but for structural<br />

analysis the largest one was considered,<br />

since can be assumed as the critical case in<br />

due to supporting larger pressure, larger<br />

dimensions, thus, larger bending moments.<br />

The analysis also considered the most<br />

critical situation for the rack that is on the<br />

ground, since it will support another two<br />

stacked racks.<br />

The structures were dimensioned with<br />

profiles of 30x40x2 mm for bars where the<br />

forces are higher and profiles of 30x30x2<br />

mm for trusses, both of them made of steel<br />

1020, totalizing a weight of 25 kN to<br />

support.<br />

Then, using specific boundary conditions for<br />

the problem, von Misses criteria and “iso<br />

clipping” tool, through the software<br />

SolidWorks, the following simulation was<br />

obtained.<br />

Maximum stress: 3.567 × 10 7 NN mm 2<br />

Maximum displacement: 0.382 mm<br />

Factor of security obtained: 9.8<br />

The structure supported all the load pressure of two racks stacked with<br />

all tires without ruptures or any propensity to fatigue.<br />

Traceability Program<br />

The main objective of traceability is to provide the story, usage and<br />

location of a single product or a set of products through a unique<br />

number of identification.<br />

In order to assist on documentation and tracking of tires, a computer<br />

programme was created, which will be utilized by employees in charge of<br />

maintenance and tires transport, helping to organize the inventory.<br />

Project Supervisor<br />

Dr. Tushar Dhavale<br />

Project summary<br />

An investigation has been done to develop a whole<br />

new storage rack for aircraft tires. This new design<br />

was necessary in order to solve some problems<br />

caused by poor storage which causes distortion and<br />

folds over the rubber. On this storage rack, the tires<br />

lay over rollers and can be rotated by using a drill or<br />

human force which decrease the probability of<br />

formation of folds or distortion on the tires in due to<br />

an equal pressure over all their parts.<br />

Traceability is another differential: using a computer<br />

with the programme developed, the operator can<br />

track and search the exact location of a specific tire,<br />

as well as its information about inspection and<br />

maintenance.<br />

Project Objectives<br />

The purpose of the project is to become capable to<br />

create a whole storage rack that rotates the tires in<br />

order to prevent folds over the tire rubber and<br />

extend their life cycle with a traceability programme<br />

to track and find information about tires stored.<br />

Project Conclusion<br />

• A new design of a storage rack was developed as<br />

expected. Observing similar projects enabled us to<br />

find a differential for this rack, which is store tires<br />

with quality and control of process without high<br />

efforts to rotate tires, doing it manually or<br />

automatically.<br />

• The rack designed has the capacity to store four<br />

tires and also can be stacked with the maximum of<br />

two others racks. The structure was modelled and<br />

simulated using the software SolidWorks and could<br />

support all the load required.<br />

• The project also reached successfully on design<br />

and selection of proper components. The<br />

reduction system allows the operator to rotate the<br />

four tires at the same time using low human force<br />

or using a drill, facilitating the process of<br />

maintenance and security.<br />

• The traceability programme developed was very<br />

efficient, simple, with easy layout and can be used<br />

without any difficult to find any tire or information.<br />

This totally contribute to the organization and the<br />

process of supply chain industry.