UWE Bristol Engineering showcase 2015

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Christopher Farndon<br />

BEng Aerospace Design <strong>Engineering</strong><br />

Project Supervisor<br />

Dr. Chris Toomer<br />

Investigation, creation and validation of an inverse design code for twodimensional<br />

aerofoils using MATLAB<br />

Creation of MATLAB model<br />

After completing a thorough literature<br />

survey, it was decided that the most suitable<br />

method of inverse design for this project was<br />

the Modified Garabedian McFadden (MGM)<br />

method. This approach uses coefficient of<br />

pressure distributions to compute a residual<br />

value between a target and initial Cp<br />

distribution, with this driving an iteration<br />

process which optimises an initial aerofoil<br />

shape. The fundamental equation used to<br />

compute the aerofoil change is:<br />

AA δδδδ + BB ∂∂(δδδδ)<br />

∂∂∂∂<br />

− CC ∂∂2 δδδδ<br />

∂∂xx 2<br />

= CCCC tttttttttttt − CCCC iiiiiiiiiiiiii<br />

This second order ordinary differential<br />

equation can be solved using a central finite<br />

difference method for δδδδ (the change in<br />

aerofoil height) which can then be added to<br />

the initial aerofoil to create a new shape<br />

closer to the required aerofoil. This process<br />

is repeated in an iterative loop until the Cp<br />

residual is reduced to 0 (or a negligible value)<br />

indicating the aerofoil has been optimised<br />

correctly.<br />

Tri-diagonal sparse matrix created to solve the fundamental equation<br />

Validation<br />

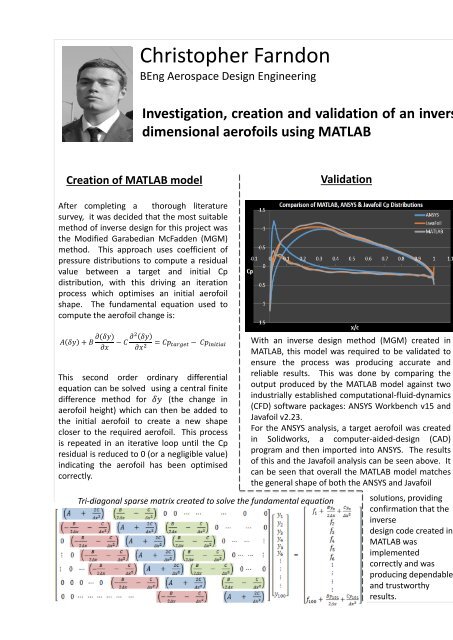

With an inverse design method (MGM) created in<br />

MATLAB, this model was required to be validated to<br />

ensure the process was producing accurate and<br />

reliable results. This was done by comparing the<br />

output produced by the MATLAB model against two<br />

industrially established computational-fluid-dynamics<br />

(CFD) software packages: ANSYS Workbench v15 and<br />

Javafoil v2.23.<br />

For the ANSYS analysis, a target aerofoil was created<br />

in Solidworks, a computer-aided-design (CAD)<br />

program and then imported into ANSYS. The results<br />

of this and the Javafoil analysis can be seen above. It<br />

can be seen that overall the MATLAB model matches<br />

the general shape of both the ANSYS and Javafoil<br />

solutions, providing<br />

confirmation that the<br />

inverse<br />

design code created in<br />

MATLAB was<br />

implemented<br />

correctly and was<br />

producing dependable<br />

and trustworthy<br />

results.<br />

Testing<br />

The testing phase allowed the capabilities of the<br />

developed MATLAB inverse design code to be<br />

investigated. A variety of test series were<br />

created; each assessing a different aspect of the<br />

program’s functionality. The constants A, B and<br />

C seen in the fundamental equation were<br />

required to be determined experimentally, as<br />

well as the optimal value of the Cp error. Once<br />

these were determined, various tests were<br />

performed to observe the MATLAB’s success at<br />

transforming an initial aerofoil shape based on a<br />

variety of key aerofoil design parameters:<br />

camber, maximum thickness and the position of<br />

the maximum thickness.<br />

These tests were all passed with overwhelming<br />

success, with the inverse design code efficiently<br />

optimising the aerofoil shape to within an<br />

acceptable level of accuracy for any change in<br />

design criteria.<br />

The testing phase continued on to assess the<br />

MATLAB model’s ability to analyse viscous flows,<br />

where it also successfully passed this, increasing<br />

the flexibility and usefulness of the algorithm.<br />

3D representation of change in aerofoil shape over time.<br />

Project summary<br />

The project attempted to gain an<br />

understanding of inverse design methods<br />

when applied to the aerospace industry, by<br />

creating, validating and testing a working<br />

model from first-principles.<br />

Project Objectives<br />

Overall project objectives:<br />

• Create an inverse design code in MATLAB.<br />

• Use computational-fluid-dynamics (CFD)<br />

to validate the output of the inverse<br />

design code .<br />

• Devise and complete a comprehensive set<br />

of test procedures to investigate the<br />

program’s ability to successfully optimise<br />

an aerofoil based on a variety of varying<br />

design criteria.<br />

Project Conclusion<br />

An inverse design code was successfully<br />

created in MATLAB, before being validated<br />

and tested to confirm the program produced<br />

accurate and reliable aerofoil shapes. The<br />

developed program provided not only a<br />

useful aerodynamic design tool, but also<br />

served as an opportunity to observe the<br />

concepts and principles associated with<br />

inverse design first hand by creating a<br />

working model first-hand.