ssw03_plus_series

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

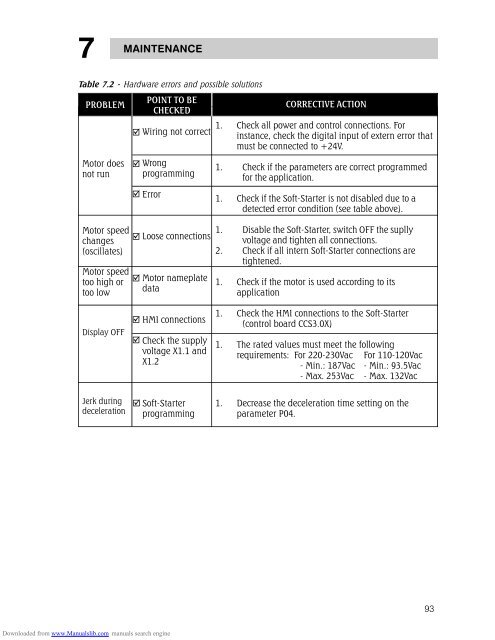

7 MAINTENANCE<br />

Table 7.2 - Hardware errors and possible solutions<br />

PROBLEM<br />

Motor does<br />

not run<br />

Motor speed<br />

changes<br />

(oscillates)<br />

Motor speed<br />

too high or<br />

too low<br />

POINT TO BE<br />

CHECKED<br />

Wiring not correct<br />

<br />

Wrong<br />

programming<br />

Error<br />

Loose connections<br />

<br />

Motor nameplate<br />

data<br />

CORRECTIVE ACTION<br />

1. Check all power and control connections. For<br />

instance, check the digital input of extern error that<br />

must be connected to +24V.<br />

1. Check if the parameters are correct programmed<br />

for the application.<br />

1. Check if the Soft-Starter is not disabled due to a<br />

detected error condition (see table above).<br />

1. Disable the Soft-Starter, switch OFF the suplly<br />

voltage and tighten all connections.<br />

2. Check if all intern Soft-Starter connections are<br />

tightened.<br />

1. Check if the motor is used according to its<br />

application<br />

Display OFF<br />

HMI connections<br />

<br />

Check the supply<br />

voltage X1.1 and<br />

X1.2<br />

1. Check the HMI connections to the Soft-Starter<br />

(control board CCS3.0X)<br />

1. The rated values must meet the following<br />

requirements: For 220-230Vac For 110-120Vac<br />

- Min.: 187Vac - Min.: 93.5Vac<br />

- Max. 253Vac - Max. 132Vac<br />

Jerk during<br />

deceleration<br />

Soft-Starter<br />

programming<br />

1. Decrease the deceleration time setting on the<br />

parameter P04.<br />

93<br />

Downloaded from www.Manualslib.com manuals search engine