certific at e - NOC international

certific at e - NOC international

certific at e - NOC international

Erfolgreiche ePaper selbst erstellen

Machen Sie aus Ihren PDF Publikationen ein blätterbares Flipbook mit unserer einzigartigen Google optimierten e-Paper Software.

Extended modified service life<br />

The factor a 1 is merely for st<strong>at</strong>istical use and may be selected from the table below according to the probability of<br />

failure required. Please note th<strong>at</strong> the service life end probability is 90% only if the r<strong>at</strong>ing life is determined according<br />

to DIN ISO 281.<br />

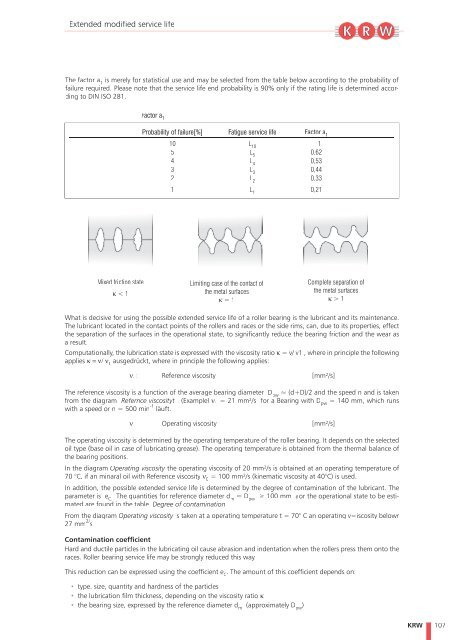

Mixed friction st<strong>at</strong>e<br />

κ < 1<br />

Factor a 1<br />

Probability of failure[%] F<strong>at</strong>igue service life Factor a 1<br />

10 L 10 1<br />

5 L 5 0,62<br />

4 L 4 0,53<br />

3 L 3 0,44<br />

2 L 2 0,33<br />

1 L 1 0,21<br />

Limiting case of the contact of<br />

the metal surfaces<br />

κ = 1<br />

Wh<strong>at</strong> is decisive for using the possible extended service life of a roller bearing is the lubricant and its maintenance.<br />

The lubricant loc<strong>at</strong>ed in the contact points of the rollers and races or the side rims, can, due to its properties, effect<br />

the separ<strong>at</strong>ion of the surfaces in the oper<strong>at</strong>ional st<strong>at</strong>e, to significantly reduce the bearing friction and the wear as<br />

a result.<br />

Comput<strong>at</strong>ionally, the lubric<strong>at</strong>ion st<strong>at</strong>e is expressed with the viscosity r<strong>at</strong>io κ = v/ v1 , where in principle the following<br />

applies κ = ν/ ν 1 ausgedrückt, where in principle the following applies:<br />

ν 1 : Reference viscosity [mm²/s]<br />

The reference viscosity is a function of the average bearing diameter D pw ≈ (d+D)/2 and the speed n and is taken<br />

from the diagram Refernce viscosity viscosit t . (Examplel ν1 = 21 mm²/s for a Bearing with D Dpw<br />

= 140 mm, which runs<br />

with a speed or n = 500 min -1 läuft.<br />

ν: Oper<strong>at</strong>ing viscosity [mm²/s]<br />

The oper<strong>at</strong>ing viscosity is determined by the oper<strong>at</strong>ing temper<strong>at</strong>ure of the roller bearing. It depends on the selected<br />

oil type (base oil in case of lubric<strong>at</strong>ing grease). The oper<strong>at</strong>ing temper<strong>at</strong>ure is obtained from the thermal balance of<br />

the bearing positions.<br />

In the diagram Oper<strong>at</strong>ing viscosity the oper<strong>at</strong>ing viscosity of 20 mm²/s is obtained <strong>at</strong> an oper<strong>at</strong>ing temper<strong>at</strong>ure of<br />

70 °C, if an minaral oil with Reference viscosity ν0 = 100 mm²/s (kinem<strong>at</strong>ic viscosity <strong>at</strong> 40°C) is used.<br />

In addition, the possible extended service life is determined by the degree of contamin<strong>at</strong>ion of the lubricant. The<br />

parameter is e C. The quantities for reference diameter d m ≈ D pw ≥ 100 mm aor the oper<strong>at</strong>ional st<strong>at</strong>e to be estim<strong>at</strong>ed<br />

are found in the table Degree of contamin<strong>at</strong>ion<br />

From the diagram Oper<strong>at</strong>ing viscosity is taken <strong>at</strong> a oper<strong>at</strong>ing temper<strong>at</strong>ure t = 70° C an oper<strong>at</strong>ing v=iscosity belowr<br />

27 mm 2/<br />

From the diagram<br />

2/<br />

s<br />

Contamin<strong>at</strong>ion coefficient<br />

Hard and ductile particles in the lubric<strong>at</strong>ing oil cause abrasion and indent<strong>at</strong>ion when the rollers press them onto the<br />

races. Roller bearing service life may be strongly reduced this way.<br />

This reduction can be expressed using the coefficient e C . The amount of this coefficient depends on:<br />

• type. size, quantity and hardness of the particles<br />

• the lubric<strong>at</strong>ion film thickness, depending on the viscosity r<strong>at</strong>io κ<br />

• the bearing size, expressed by the reference diameter d m (approxim<strong>at</strong>ely D pw )<br />

Complete separ<strong>at</strong>ion of<br />

the metal surfaces<br />

κ > 1<br />

KRW 107