fundamentals of engineering supplied-reference handbook - Ventech!

fundamentals of engineering supplied-reference handbook - Ventech!

fundamentals of engineering supplied-reference handbook - Ventech!

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Bed Expansion<br />

Monosized Multisized<br />

Lo<br />

( 1−<br />

ηo<br />

)<br />

L fb =<br />

L = ( 1−<br />

η )∑<br />

0.<br />

22 fb Lo<br />

o<br />

⎛V<br />

⎞<br />

1−<br />

⎜ B<br />

⎟<br />

⎝ Vt<br />

⎠<br />

0. 22<br />

⎛ VB<br />

⎞<br />

η fb = ⎜ ⎟<br />

⎜ V ⎟<br />

, where<br />

t<br />

⎝<br />

⎠<br />

Lfb = depth <strong>of</strong> fluidized filter media (m),<br />

VB = backwash velocity (m/s), Q/Aplan,<br />

Vt = terminal setting velocity, and<br />

ηfb = porosity <strong>of</strong> fluidized bed.<br />

Lo = initial bed depth<br />

ηo = initial bed porosity<br />

Lime-Soda S<strong>of</strong>tening Equations<br />

50 mg/L as CaCO3 equivalent = 1 meq/L<br />

1. Carbon dioxide removal<br />

CO2 + Ca (OH)2 → CaCO3(s) + H2O<br />

x<br />

⎛<br />

⎜<br />

V<br />

1−<br />

⎜<br />

⎝<br />

Vt,<br />

ij<br />

B<br />

i,<br />

j<br />

2. Calcium carbonate hardness removal<br />

Ca (HCO3)2 + Ca (OH)2 → 2CaCO3(s) + 2H2O<br />

3. Calcium non-carbonate hardness removal<br />

CaSO4 + Na2CO3 → CaCO3(s) + 2Na + + SO4 –2<br />

4. Magnesium carbonate hardness removal<br />

Mg(HCO3)2 + 2Ca(OH)2 → 2CaCO3(s) +<br />

Mg(OH)2(s) + 2H2O<br />

5. Magnesium non-carbonate hardness removal<br />

MgSO4 + Ca(OH)2 + Na2CO3 → CaCO3(s) +<br />

Mg(OH)2(s) + 2Na + + SO4 2–<br />

6. Destruction <strong>of</strong> excess alkalinity<br />

⎞<br />

⎟<br />

⎠<br />

0.<br />

22<br />

2HCO3 – + Ca(OH)2 → CaCO3(s) + CO3 2– + 2H2O<br />

7. Recarbonation<br />

Ca 2+ + 2OH – + CO2 → CaCO3(s) + H2O<br />

164<br />

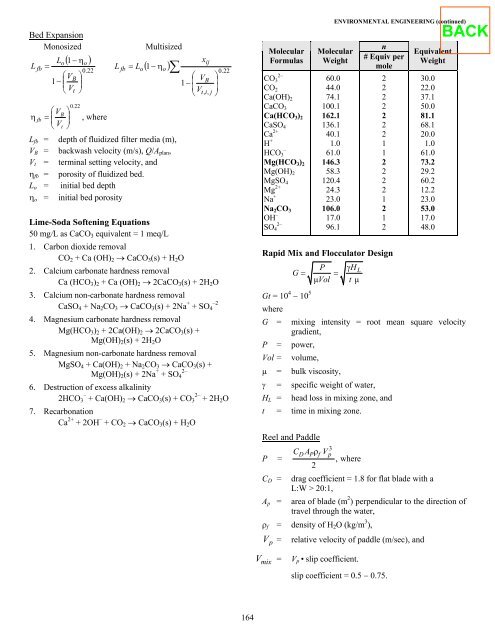

Molecular<br />

Formulas<br />

CO3 2–<br />

CO2<br />

Ca(OH)2<br />

CaCO3<br />

Ca(HCO3)2<br />

CaSO4<br />

Ca 2+<br />

H +<br />

HCO3 –<br />

Mg(HCO3)2<br />

Mg(OH)2<br />

MgSO4<br />

Mg 2+<br />

Na +<br />

Na2CO3<br />

OH –<br />

SO4 2–<br />

ENVIRONMENTAL ENGINEERING (continued)<br />

Molecular<br />

Weight<br />

60.0<br />

44.0<br />

74.1<br />

100.1<br />

162.1<br />

136.1<br />

40.1<br />

1.0<br />

61.0<br />

146.3<br />

58.3<br />

120.4<br />

24.3<br />

23.0<br />

106.0<br />

17.0<br />

96.1<br />

n<br />

# Equiv per<br />

mole<br />

2<br />

2<br />

2<br />

2<br />

2<br />

2<br />

2<br />

1<br />

1<br />

2<br />

2<br />

2<br />

2<br />

1<br />

2<br />

1<br />

2<br />

Rapid Mix and Flocculator Design<br />

G =<br />

P<br />

=<br />

µ Vol<br />

γH<br />

L<br />

t µ<br />

Equivalent<br />

Weight<br />

30.0<br />

22.0<br />

37.1<br />

50.0<br />

81.1<br />

68.1<br />

20.0<br />

1.0<br />

61.0<br />

73.2<br />

29.2<br />

60.2<br />

12.2<br />

23.0<br />

53.0<br />

17.0<br />

48.0<br />

Gt = 10 4 − 10 5<br />

where<br />

G = mixing intensity = root mean square velocity<br />

gradient,<br />

P = power,<br />

Vol = volume,<br />

µ = bulk viscosity,<br />

γ = specific weight <strong>of</strong> water,<br />

HL = head loss in mixing zone, and<br />

t = time in mixing zone.<br />

Reel and Paddle<br />

P =<br />

C A ρ V<br />

2<br />

3<br />

D P f p<br />

,where<br />

CD = drag coefficient = 1.8 for flat blade with a<br />

L:W > 20:1,<br />

Ap = area <strong>of</strong> blade (m 2 ) perpendicular to the direction <strong>of</strong><br />

travel through the water,<br />

ρf = density <strong>of</strong> H2O (kg/m 3 ),<br />

V p = relative velocity <strong>of</strong> paddle (m/sec), and<br />

V mix = Vp • slip coefficient.<br />

slip coefficient = 0.5 − 0.75.