fundamentals of engineering supplied-reference handbook - Ventech!

fundamentals of engineering supplied-reference handbook - Ventech!

fundamentals of engineering supplied-reference handbook - Ventech!

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

COMPOSITE MATERIALS<br />

ρc = Σ fiρi<br />

Cc = Σ fici<br />

⎡ ⎤<br />

⎢ ⎥<br />

⎣ ⎦<br />

−1<br />

fi<br />

∑ ≤ E ≤ f E<br />

c ∑ i i<br />

Ei<br />

ρc = density <strong>of</strong> composite,<br />

Cc = heat capacity <strong>of</strong> composite per unit volume,<br />

Ec = Young's modulus <strong>of</strong> composite,<br />

fi = volume fraction <strong>of</strong> individual material,<br />

ci = heat capacity <strong>of</strong> individual material per unit<br />

volume, and<br />

Ei = Young's modulus <strong>of</strong> individual material.<br />

Also, for axially oriented long fiber reinforced composites,<br />

the strains <strong>of</strong> the two components are equal.<br />

∆L =<br />

(∆L/L)1 = (∆L/L)2<br />

change in length <strong>of</strong> the composite,<br />

L = original length <strong>of</strong> the composite.<br />

HALF-LIFE<br />

N = Noe –0.693t/τ , where<br />

No = original number <strong>of</strong> atoms,<br />

N = final number <strong>of</strong> atoms,<br />

t = time, and<br />

τ = half-life.<br />

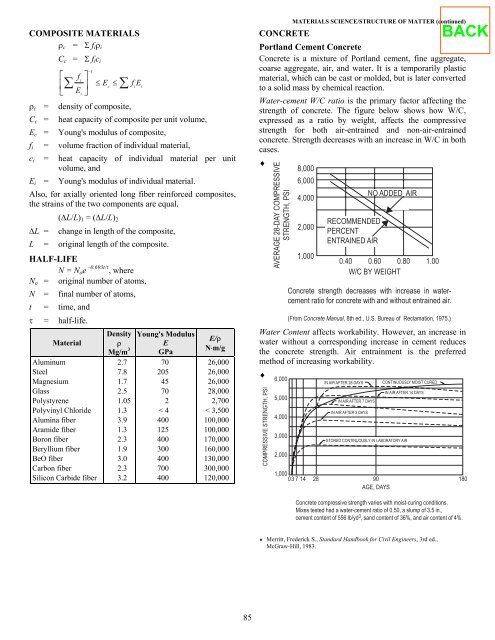

Material<br />

Aluminum<br />

Steel<br />

Magnesium<br />

Glass<br />

Polystyrene<br />

Polyvinyl Chloride<br />

Alumina fiber<br />

Aramide fiber<br />

Boron fiber<br />

Beryllium fiber<br />

BeO fiber<br />

Carbon fiber<br />

Silicon Carbide fiber<br />

Density<br />

ρ<br />

Mg/m 3<br />

2.7<br />

7.8<br />

1.7<br />

2.5<br />

1.05<br />

1.3<br />

3.9<br />

1.3<br />

2.3<br />

1.9<br />

3.0<br />

2.3<br />

3.2<br />

Young's Modulus<br />

E<br />

GPa<br />

70<br />

205<br />

45<br />

70<br />

2<br />

< 4<br />

400<br />

125<br />

400<br />

300<br />

400<br />

700<br />

400<br />

E/ρ<br />

N⋅m/g<br />

26,000<br />

26,000<br />

26,000<br />

28,000<br />

2,700<br />

< 3,500<br />

100,000<br />

100,000<br />

170,000<br />

160,000<br />

130,000<br />

300,000<br />

120,000<br />

85<br />

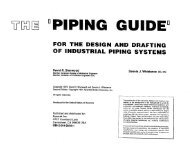

COMPRESSIVE STRENGTH, PSI<br />

AVERAGE 28-DAY COMPRESSIVE<br />

STRENGTH, PSI<br />

6,000<br />

5,000<br />

4,000<br />

3,000<br />

2,000<br />

MATERIALS SCIENCE/STRUCTURE OF MATTER (continued)<br />

CONCRETE<br />

Portland Cement Concrete<br />

Concrete is a mixture <strong>of</strong> Portland cement, fine aggregate,<br />

coarse aggregate, air, and water. It is a temporarily plastic<br />

material, which can be cast or molded, but is later converted<br />

to a solid mass by chemical reaction.<br />

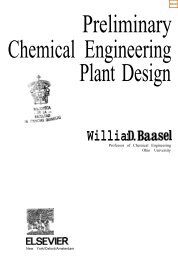

Water-cement W/C ratio is the primary factor affecting the<br />

strength <strong>of</strong> concrete. The figure below shows how W/C,<br />

expressed as a ratio by weight, affects the compressive<br />

strength for both air-entrained and non-air-entrained<br />

concrete. Strength decreases with an increase in W/C in both<br />

cases.<br />

♦<br />

8,000<br />

6,000<br />

NO ADDED AIR<br />

4,000<br />

2,000<br />

1,000<br />

RECOMMENDED<br />

PERCENT<br />

ENTRAINED AIR<br />

0.40 0.60 0.80 1.00<br />

W/C BY WEIGHT<br />

Concrete strength decreases with increase in watercement<br />

ratio for concrete with and without entrained air.<br />

(From Concrete Manual, 8th ed., U.S. Bureau <strong>of</strong> Reclamation, 1975.)<br />

Water Content affects workability. However, an increase in<br />

water without a corresponding increase in cement reduces<br />

the concrete strength. Air entrainment is the preferred<br />

method <strong>of</strong> increasing workability.<br />

♦<br />

IN AIR AFTER 28 DAYS<br />

IN AIR AFTER 7 DAYS<br />

IN AIR AFTER 3 DAYS<br />

IN AIR AFTER 14 DAYS<br />

STORED CONTINUOUSLY IN LABORATORY AIR<br />

CONTINUOUSLY MOIST CURED<br />

1,000<br />

03<br />

7 14 28 90<br />

AGE, DAYS<br />

180<br />

Concrete compressive strength varies with moist-curing conditions.<br />

Mixes tested had a water-cement ratio <strong>of</strong> 0.50, a slump <strong>of</strong> 3.5 in.,<br />

cement content <strong>of</strong> 556 lb/yd 3 , sand content <strong>of</strong> 36%, and air content <strong>of</strong> 4%.<br />

♦ Merritt, Frederick S., Standard Handbook for Civil Engineers, 3rd ed.,<br />

McGraw-Hill, 1983.