fundamentals of engineering supplied-reference handbook - Ventech!

fundamentals of engineering supplied-reference handbook - Ventech!

fundamentals of engineering supplied-reference handbook - Ventech!

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

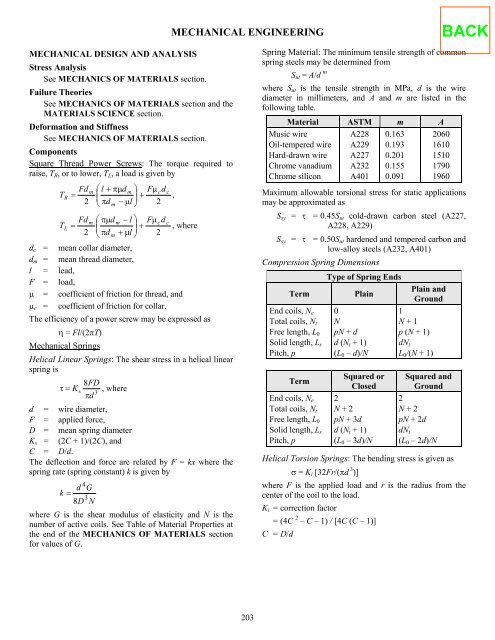

MECHANICAL DESIGN AND ANALYSIS<br />

Stress Analysis<br />

See MECHANICS OF MATERIALS section.<br />

Failure Theories<br />

See MECHANICS OF MATERIALS section and the<br />

MATERIALS SCIENCE section.<br />

Deformation and Stiffness<br />

See MECHANICS OF MATERIALS section.<br />

Components<br />

Square Thread Power Screws: The torque required to<br />

raise, TR, or to lower, TL, a load is given by<br />

T<br />

T<br />

R<br />

L<br />

Fd<br />

=<br />

2<br />

m<br />

⎛ l + πµ d m ⎞ Fµ<br />

cd<br />

⎜ ⎟<br />

⎜<br />

+<br />

d m l ⎟<br />

⎝ π − µ ⎠ 2<br />

Fd m ⎛ πµ d m − l ⎞ Fµ<br />

cd<br />

c<br />

= ⎜ ⎟ +<br />

2 ⎜ d m l ⎟<br />

, where<br />

⎝ π + µ ⎠ 2<br />

dc = mean collar diameter,<br />

dm = mean thread diameter,<br />

l = lead,<br />

F = load,<br />

µ = coefficient <strong>of</strong> friction for thread, and<br />

µc = coefficient <strong>of</strong> friction for collar.<br />

The efficiency <strong>of</strong> a power screw may be expressed as<br />

η = Fl/(2πT)<br />

Mechanical Springs<br />

Helical Linear Springs: The shear stress in a helical linear<br />

spring is<br />

8FD<br />

τ = Ks , where<br />

3<br />

πd<br />

d = wire diameter,<br />

F = applied force,<br />

D = mean spring diameter<br />

Ks = (2C + 1)/(2C), and<br />

C = D/d.<br />

The deflection and force are related by F = kx where the<br />

spring rate (spring constant) k is given by<br />

4<br />

d G<br />

k =<br />

3<br />

8D<br />

N<br />

where G is the shear modulus <strong>of</strong> elasticity and N is the<br />

number <strong>of</strong> active coils. See Table <strong>of</strong> Material Properties at<br />

the end <strong>of</strong> the MECHANICS OF MATERIALS section<br />

for values <strong>of</strong> G.<br />

c<br />

MECHANICAL ENGINEERING<br />

,<br />

203<br />

Spring Material: The minimum tensile strength <strong>of</strong> common<br />

spring steels may be determined from<br />

Sut = A/d m<br />

where Sut is the tensile strength in MPa, d is the wire<br />

diameter in millimeters, and A and m are listed in the<br />

following table.<br />

Material ASTM m A<br />

Music wire<br />

Oil-tempered wire<br />

Hard-drawn wire<br />

Chrome vanadium<br />

Chrome silicon<br />

A228<br />

A229<br />

A227<br />

A232<br />

A401<br />

0.163<br />

0.193<br />

0.201<br />

0.155<br />

0.091<br />

2060<br />

1610<br />

1510<br />

1790<br />

1960<br />

Maximum allowable torsional stress for static applications<br />

may be approximated as<br />

Ssy = τ = 0.45Sut cold-drawn carbon steel (A227,<br />

A228, A229)<br />

Ssy = τ = 0.50Sut hardened and tempered carbon and<br />

low-alloy steels (A232, A401)<br />

Compression Spring Dimensions<br />

Type <strong>of</strong> Spring Ends<br />

Term Plain<br />

End coils, Ne<br />

Total coils, Nt<br />

Free length, L0<br />

Solid length, Ls<br />

Pitch, p<br />

Term<br />

End coils, Ne<br />

Total coils, Nt<br />

Free length, L0<br />

Solid length, Ls<br />

Pitch, p<br />

0<br />

N<br />

pN + d<br />

d (Nt + 1)<br />

(L0 – d)/N<br />

Squared or<br />

Closed<br />

2<br />

N + 2<br />

pN + 3d<br />

d (Nt + 1)<br />

(L0 – 3d)/N<br />

Plain and<br />

Ground<br />

1<br />

N + 1<br />

p (N + 1)<br />

dNt<br />

L0/(N + 1)<br />

Squared and<br />

Ground<br />

2<br />

N + 2<br />

pN + 2d<br />

dNt<br />

(L0 – 2d)/N<br />

Helical Torsion Springs: The bending stress is given as<br />

σ = Ki [32Fr/(πd 3 )]<br />

where F is the applied load and r is the radius from the<br />

center <strong>of</strong> the coil to the load.<br />

Ki = correction factor<br />

= (4C 2 – C – 1) / [4C (C – 1)]<br />

C = D/d