Properties of hemp fibre polymer composites -An optimisation of ...

Properties of hemp fibre polymer composites -An optimisation of ...

Properties of hemp fibre polymer composites -An optimisation of ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

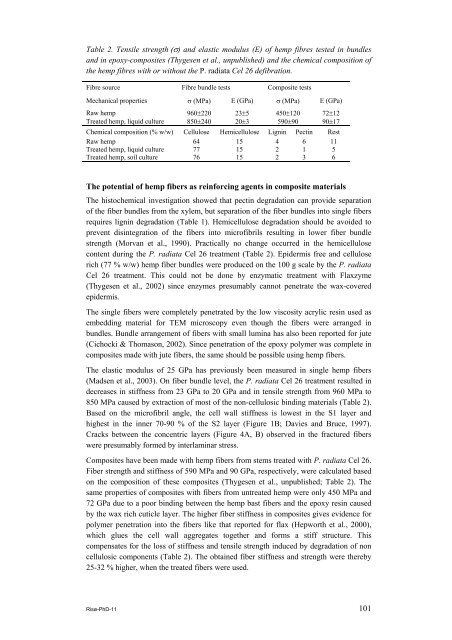

Table 2. Tensile strength (σ) and elastic modulus (E) <strong>of</strong> <strong>hemp</strong> <strong>fibre</strong>s tested in bundles<br />

and in epoxy-<strong>composites</strong> (Thygesen et al., unpublished) and the chemical composition <strong>of</strong><br />

the <strong>hemp</strong> <strong>fibre</strong>s with or without the P. radiata Cel 26 defibration.<br />

Fibre source Fibre bundle tests Composite tests<br />

Mechanical properties σ (MPa) E (GPa) σ (MPa) E (GPa)<br />

Raw <strong>hemp</strong> 960±220 23±5 450±120 72±12<br />

Treated <strong>hemp</strong>, liquid culture 850±240 20±3 590±90 90±17<br />

Chemical composition (% w/w) Cellulose Hemicellulose Lignin Pectin Rest<br />

Raw <strong>hemp</strong> 64 15 4 6 11<br />

Treated <strong>hemp</strong>, liquid culture 77 15 2 1 5<br />

Treated <strong>hemp</strong>, soil culture 76 15 2 3 6<br />

The potential <strong>of</strong> <strong>hemp</strong> fibers as reinforcing agents in composite materials<br />

The histochemical investigation showed that pectin degradation can provide separation<br />

<strong>of</strong> the fiber bundles from the xylem, but separation <strong>of</strong> the fiber bundles into single fibers<br />

requires lignin degradation (Table 1). Hemicellulose degradation should be avoided to<br />

prevent disintegration <strong>of</strong> the fibers into micr<strong>of</strong>ibrils resulting in lower fiber bundle<br />

strength (Morvan et al., 1990). Practically no change occurred in the hemicellulose<br />

content during the P. radiata Cel 26 treatment (Table 2). Epidermis free and cellulose<br />

rich (77 % w/w) <strong>hemp</strong> fiber bundles were produced on the 100 g scale by the P. radiata<br />

Cel 26 treatment. This could not be done by enzymatic treatment with Flaxzyme<br />

(Thygesen et al., 2002) since enzymes presumably cannot penetrate the wax-covered<br />

epidermis.<br />

The single fibers were completely penetrated by the low viscosity acrylic resin used as<br />

embedding material for TEM microscopy even though the fibers were arranged in<br />

bundles. Bundle arrangement <strong>of</strong> fibers with small lumina has also been reported for jute<br />

(Cichocki & Thomason, 2002). Since penetration <strong>of</strong> the epoxy <strong>polymer</strong> was complete in<br />

<strong>composites</strong> made with jute fibers, the same should be possible using <strong>hemp</strong> fibers.<br />

The elastic modulus <strong>of</strong> 25 GPa has previously been measured in single <strong>hemp</strong> fibers<br />

(Madsen et al., 2003). On fiber bundle level, the P. radiata Cel 26 treatment resulted in<br />

decreases in stiffness from 23 GPa to 20 GPa and in tensile strength from 960 MPa to<br />

850 MPa caused by extraction <strong>of</strong> most <strong>of</strong> the non-cellulosic binding materials (Table 2).<br />

Based on the micr<strong>of</strong>ibril angle, the cell wall stiffness is lowest in the S1 layer and<br />

highest in the inner 70-90 % <strong>of</strong> the S2 layer (Figure 1B; Davies and Bruce, 1997).<br />

Cracks between the concentric layers (Figure 4A, B) observed in the fractured fibers<br />

were presumably formed by interlaminar stress.<br />

Composites have been made with <strong>hemp</strong> fibers from stems treated with P. radiata Cel 26.<br />

Fiber strength and stiffness <strong>of</strong> 590 MPa and 90 GPa, respectively, were calculated based<br />

on the composition <strong>of</strong> these <strong>composites</strong> (Thygesen et al., unpublished; Table 2). The<br />

same properties <strong>of</strong> <strong>composites</strong> with fibers from untreated <strong>hemp</strong> were only 450 MPa and<br />

72 GPa due to a poor binding between the <strong>hemp</strong> bast fibers and the epoxy resin caused<br />

by the wax rich cuticle layer. The higher fiber stiffness in <strong>composites</strong> gives evidence for<br />

<strong>polymer</strong> penetration into the fibers like that reported for flax (Hepworth et al., 2000),<br />

which glues the cell wall aggregates together and forms a stiff structure. This<br />

compensates for the loss <strong>of</strong> stiffness and tensile strength induced by degradation <strong>of</strong> non<br />

cellulosic components (Table 2). The obtained fiber stiffness and strength were thereby<br />

25-32 % higher, when the treated fibers were used.<br />

Risø-PhD-11 101