Properties of hemp fibre polymer composites -An optimisation of ...

Properties of hemp fibre polymer composites -An optimisation of ...

Properties of hemp fibre polymer composites -An optimisation of ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Sample crystallinity [% w/w] .<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

0 20 40 60 80 100<br />

Cellulose content [% w/w]<br />

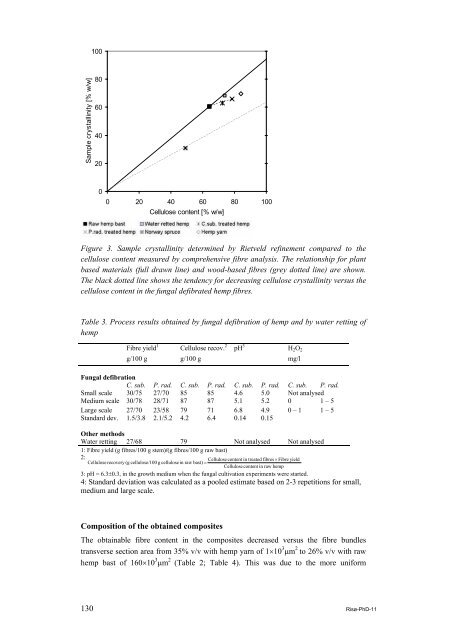

Figure 3. Sample crystallinity determined by Rietveld refinement compared to the<br />

cellulose content measured by comprehensive <strong>fibre</strong> analysis. The relationship for plant<br />

based materials (full drawn line) and wood-based <strong>fibre</strong>s (grey dotted line) are shown.<br />

The black dotted line shows the tendency for decreasing cellulose crystallinity versus the<br />

cellulose content in the fungal defibrated <strong>hemp</strong> <strong>fibre</strong>s.<br />

Table 3. Process results obtained by fungal defibration <strong>of</strong> <strong>hemp</strong> and by water retting <strong>of</strong><br />

<strong>hemp</strong><br />

Fibre yield 1<br />

Cellulose recov. 2<br />

pH 3<br />

H2O2 g/100 g g/100 g mg/l<br />

Fungal defibration<br />

C. sub. P. rad. C. sub. P. rad. C. sub. P. rad. C. sub. P. rad.<br />

Small scale 30/75 27/70 85 85 4.6 5.0 Not analysed<br />

Medium scale 30/78 28/71 87 87 5.1 5.2 0 1 – 5<br />

Large scale 27/70 23/58 79 71 6.8 4.9 0 – 1 1 – 5<br />

Standard dev. 1.5/3.8 2.1/5.2 4.2 6.4 0.14 0.15<br />

Other methods<br />

Water retting 27/68 79 Not analysed Not analysed<br />

1: Fibre yield (g <strong>fibre</strong>s/100 g stem)/(g <strong>fibre</strong>s/100 g raw bast)<br />

2:<br />

Cellulose content in treated <strong>fibre</strong>s × Fibre yield<br />

Cellulose recovery (g cellulose/ 100 g cellulose in raw bast) =<br />

Cellulose content in raw <strong>hemp</strong><br />

3: pH = 6.3±0.3, in the growth medium when the fungal cultivation experiments were started.<br />

4: Standard deviation was calculated as a pooled estimate based on 2-3 repetitions for small,<br />

medium and large scale.<br />

Composition <strong>of</strong> the obtained <strong>composites</strong><br />

The obtainable <strong>fibre</strong> content in the <strong>composites</strong> decreased versus the <strong>fibre</strong> bundles<br />

transverse section area from 35% v/v with <strong>hemp</strong> yarn <strong>of</strong> 1×10 3 μm 2 to 26% v/v with raw<br />

<strong>hemp</strong> bast <strong>of</strong> 160×10 3 μm 2 (Table 2; Table 4). This was due to the more uniform<br />

130 Risø-PhD-11