Properties of hemp fibre polymer composites -An optimisation of ...

Properties of hemp fibre polymer composites -An optimisation of ...

Properties of hemp fibre polymer composites -An optimisation of ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

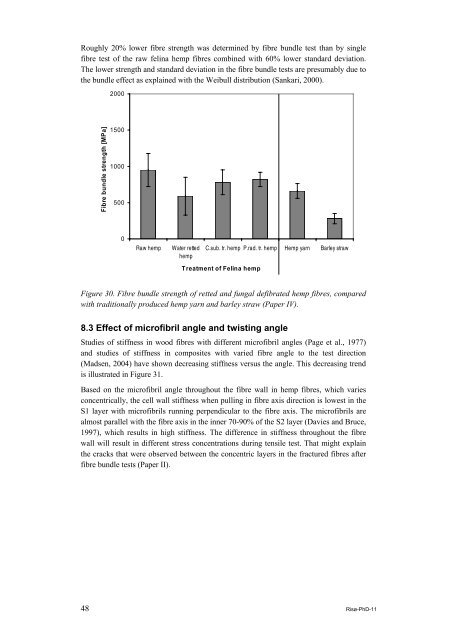

Roughly 20% lower <strong>fibre</strong> strength was determined by <strong>fibre</strong> bundle test than by single<br />

<strong>fibre</strong> test <strong>of</strong> the raw felina <strong>hemp</strong> <strong>fibre</strong>s combined with 60% lower standard deviation.<br />

The lower strength and standard deviation in the <strong>fibre</strong> bundle tests are presumably due to<br />

the bundle effect as explained with the Weibull distribution (Sankari, 2000).<br />

Fibre bundle strength [MPa]<br />

2000<br />

1500<br />

1000<br />

500<br />

0<br />

Raw <strong>hemp</strong> Water retted<br />

<strong>hemp</strong><br />

C.sub. tr. <strong>hemp</strong> P.rad. tr. <strong>hemp</strong> Hemp yarn Barley straw<br />

Treatment <strong>of</strong> Felina <strong>hemp</strong><br />

Figure 30. Fibre bundle strength <strong>of</strong> retted and fungal defibrated <strong>hemp</strong> <strong>fibre</strong>s, compared<br />

with traditionally produced <strong>hemp</strong> yarn and barley straw (Paper IV).<br />

8.3 Effect <strong>of</strong> micr<strong>of</strong>ibril angle and twisting angle<br />

Studies <strong>of</strong> stiffness in wood <strong>fibre</strong>s with different micr<strong>of</strong>ibril angles (Page et al., 1977)<br />

and studies <strong>of</strong> stiffness in <strong>composites</strong> with varied <strong>fibre</strong> angle to the test direction<br />

(Madsen, 2004) have shown decreasing stiffness versus the angle. This decreasing trend<br />

is illustrated in Figure 31.<br />

Based on the micr<strong>of</strong>ibril angle throughout the <strong>fibre</strong> wall in <strong>hemp</strong> <strong>fibre</strong>s, which varies<br />

concentrically, the cell wall stiffness when pulling in <strong>fibre</strong> axis direction is lowest in the<br />

S1 layer with micr<strong>of</strong>ibrils running perpendicular to the <strong>fibre</strong> axis. The micr<strong>of</strong>ibrils are<br />

almost parallel with the <strong>fibre</strong> axis in the inner 70-90% <strong>of</strong> the S2 layer (Davies and Bruce,<br />

1997), which results in high stiffness. The difference in stiffness throughout the <strong>fibre</strong><br />

wall will result in different stress concentrations during tensile test. That might explain<br />

the cracks that were observed between the concentric layers in the fractured <strong>fibre</strong>s after<br />

<strong>fibre</strong> bundle tests (Paper II).<br />

48 Risø-PhD-11