Properties of hemp fibre polymer composites -An optimisation of ...

Properties of hemp fibre polymer composites -An optimisation of ...

Properties of hemp fibre polymer composites -An optimisation of ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

7.3 The treatment procedures effect on cellulose crystallinity<br />

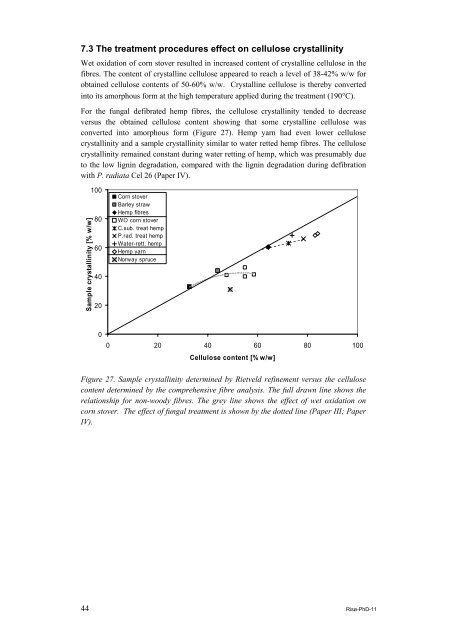

Wet oxidation <strong>of</strong> corn stover resulted in increased content <strong>of</strong> crystalline cellulose in the<br />

<strong>fibre</strong>s. The content <strong>of</strong> crystalline cellulose appeared to reach a level <strong>of</strong> 38-42% w/w for<br />

obtained cellulose contents <strong>of</strong> 50-60% w/w. Crystalline cellulose is thereby converted<br />

into its amorphous form at the high temperature applied during the treatment (190°C).<br />

For the fungal defibrated <strong>hemp</strong> <strong>fibre</strong>s, the cellulose crystallinity tended to decrease<br />

versus the obtained cellulose content showing that some crystalline cellulose was<br />

converted into amorphous form (Figure 27). Hemp yarn had even lower cellulose<br />

crystallinity and a sample crystallinity similar to water retted <strong>hemp</strong> <strong>fibre</strong>s. The cellulose<br />

crystallinity remained constant during water retting <strong>of</strong> <strong>hemp</strong>, which was presumably due<br />

to the low lignin degradation, compared with the lignin degradation during defibration<br />

with P. radiata Cel 26 (Paper IV).<br />

Sample crystallinity [% w/w]<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

Corn stover<br />

Barley straw<br />

Hemp <strong>fibre</strong>s<br />

WO corn stover<br />

C.sub. treat <strong>hemp</strong><br />

P.rad. treat <strong>hemp</strong><br />

Water-rett. <strong>hemp</strong><br />

Hemp yarn<br />

Norway spruce<br />

0 20 40 60 80 100<br />

Cellulose content [% w/w]<br />

Figure 27. Sample crystallinity determined by Rietveld refinement versus the cellulose<br />

content determined by the comprehensive <strong>fibre</strong> analysis. The full drawn line shows the<br />

relationship for non-woody <strong>fibre</strong>s. The grey line shows the effect <strong>of</strong> wet oxidation on<br />

corn stover. The effect <strong>of</strong> fungal treatment is shown by the dotted line (Paper III; Paper<br />

IV).<br />

44 Risø-PhD-11