Properties of hemp fibre polymer composites -An optimisation of ...

Properties of hemp fibre polymer composites -An optimisation of ...

Properties of hemp fibre polymer composites -An optimisation of ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

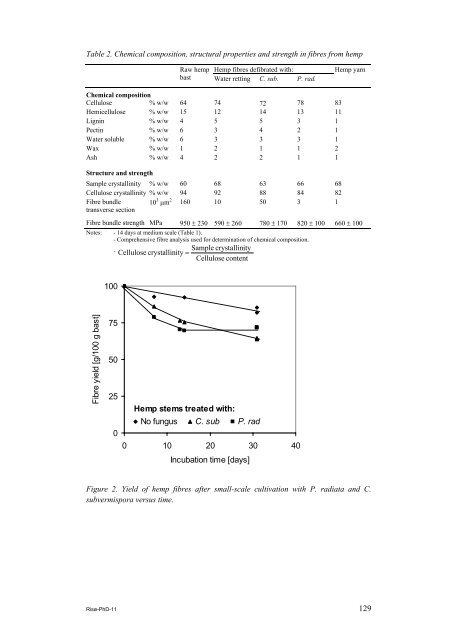

Table 2. Chemical composition, structural properties and strength in <strong>fibre</strong>s from <strong>hemp</strong><br />

Raw <strong>hemp</strong> Hemp <strong>fibre</strong>s defibrated with:<br />

bast Water retting C. sub. P. rad.<br />

Chemical composition<br />

Cellulose % w/w 64 74 72 78 83<br />

Hemicellulose % w/w 15 12 14 13 11<br />

Lignin % w/w 4 5 5 3 1<br />

Pectin % w/w 6 3 4 2 1<br />

Water soluble % w/w 6 3 3 3 1<br />

Wax % w/w 1 2 1 1 2<br />

Ash % w/w 4 2 2 1 1<br />

Structure and strength<br />

Sample crystallinity % w/w 60 68 63 66 68<br />

Cellulose crystallinity % w/w 94 92 88 84 82<br />

Fibre bundle<br />

transverse section<br />

10 3 μm 2 160 10 50 3 1<br />

Hemp yarn<br />

Fibre bundle strength MPa 950 ± 230 590 ± 260 780 ± 170 820 ± 100 660 ± 100<br />

Notes: - 14 days at medium scale (Table 1).<br />

- Comprehensive <strong>fibre</strong> analysis used for determination <strong>of</strong> chemical composition.<br />

-<br />

Sample crystallinity<br />

Cellulose crystallinity<br />

=<br />

Cellulose content<br />

Fibre yield [g/100 g bast]<br />

100<br />

75<br />

50<br />

25<br />

0<br />

Hemp stems treated with:<br />

No fungus C. sub P. rad<br />

0 10 20 30<br />

Incubation time [days]<br />

Figure 2. Yield <strong>of</strong> <strong>hemp</strong> <strong>fibre</strong>s after small-scale cultivation with P. radiata and C.<br />

subvermispora versus time.<br />

Risø-PhD-11 129<br />

40