Properties of hemp fibre polymer composites -An optimisation of ...

Properties of hemp fibre polymer composites -An optimisation of ...

Properties of hemp fibre polymer composites -An optimisation of ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

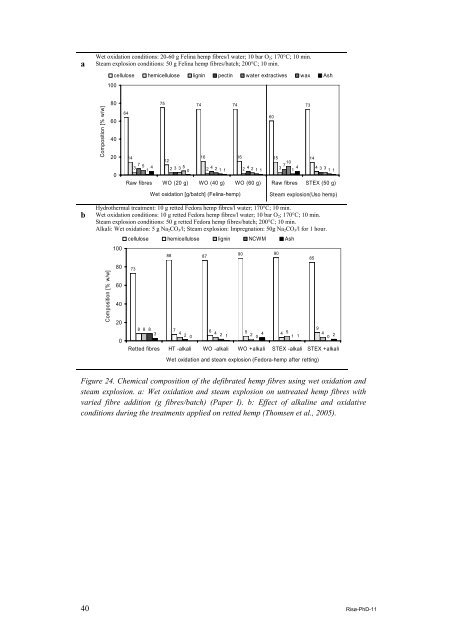

a Wet oxidation conditions: 20-60 g Felina <strong>hemp</strong> <strong>fibre</strong>s/l water; 10 bar O2; 170°C; 10 min.<br />

Steam explosion conditions: 50 g Felina <strong>hemp</strong> <strong>fibre</strong>s/batch; 200°C; 10 min.<br />

b<br />

Composition [% w/w]<br />

100<br />

80<br />

60<br />

40<br />

20<br />

cellulose hemicellulose lignin pectin water extractives wax Ash<br />

0<br />

64<br />

75 74 74<br />

14<br />

16 16 15 14<br />

12<br />

10<br />

7<br />

3<br />

5 4 2 3 2 4 2 4<br />

7<br />

3 5<br />

2 2<br />

3 4 4 3 3<br />

1<br />

0 1 1 1 1<br />

1 1 1<br />

Raw <strong>fibre</strong>s WO (20 g) WO (40 g) WO (60 g) Raw <strong>fibre</strong>s STEX (50 g)<br />

Wet oxidation [g/batch] (Felina-<strong>hemp</strong>) Steam explosion(Uso <strong>hemp</strong>)<br />

Hydrothermal treatment: 10 g retted Fedora <strong>hemp</strong> <strong>fibre</strong>s/l water; 170°C; 10 min.<br />

Wet oxidation conditions: 10 g retted Fedora <strong>hemp</strong> <strong>fibre</strong>s/l water; 10 bar O2; 170°C; 10 min.<br />

Steam explosion conditions: 50 g retted Fedora <strong>hemp</strong> <strong>fibre</strong>s/batch; 200°C; 10 min.<br />

Alkali: Wet oxidation: 5 g Na2CO3/l; Steam explosion: Impregnation: 50g Na2CO3/l for 1 hour.<br />

Composition [% w/w]<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

cellulose hemicellulose lignin NCWM Ash<br />

73<br />

88 87<br />

8 8 8<br />

7<br />

9<br />

6<br />

3<br />

4 4 5<br />

2<br />

4 5 4<br />

2<br />

2<br />

4<br />

0<br />

1<br />

0 1 1<br />

0<br />

2<br />

Retted <strong>fibre</strong>s HT -alkali WO -alkali WO +alkali STEX -alkali STEX +alkali<br />

90<br />

Wet oxidation and steam explosion (Fedora-<strong>hemp</strong> after retting)<br />

Figure 24. Chemical composition <strong>of</strong> the defibrated <strong>hemp</strong> <strong>fibre</strong>s using wet oxidation and<br />

steam explosion. a: Wet oxidation and steam explosion on untreated <strong>hemp</strong> <strong>fibre</strong>s with<br />

varied <strong>fibre</strong> addition (g <strong>fibre</strong>s/batch) (Paper I). b: Effect <strong>of</strong> alkaline and oxidative<br />

conditions during the treatments applied on retted <strong>hemp</strong> (Thomsen et al., 2005).<br />

40 Risø-PhD-11<br />

60<br />

90<br />

73<br />

85