Properties of hemp fibre polymer composites -An optimisation of ...

Properties of hemp fibre polymer composites -An optimisation of ...

Properties of hemp fibre polymer composites -An optimisation of ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

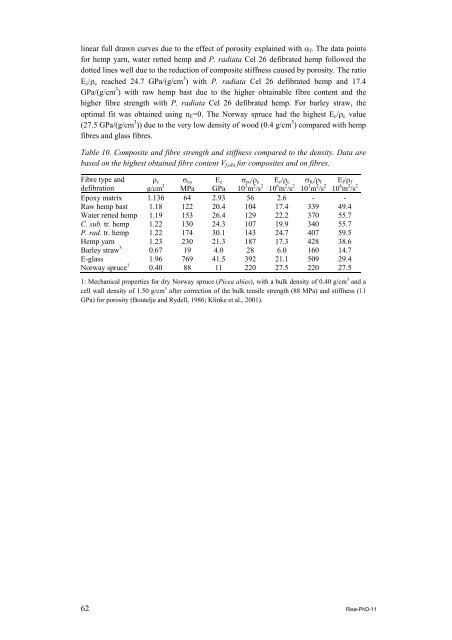

linear full drawn curves due to the effect <strong>of</strong> porosity explained with αf. The data points<br />

for <strong>hemp</strong> yarn, water retted <strong>hemp</strong> and P. radiata Cel 26 defibrated <strong>hemp</strong> followed the<br />

dotted lines well due to the reduction <strong>of</strong> composite stiffness caused by porosity. The ratio<br />

Ec/ρc reached 24.7 GPa/(g/cm 3 ) with P. radiata Cel 26 defibrated <strong>hemp</strong> and 17.4<br />

GPa/(g/cm 3 ) with raw <strong>hemp</strong> bast due to the higher obtainable <strong>fibre</strong> content and the<br />

higher <strong>fibre</strong> strength with P. radiata Cel 26 defibrated <strong>hemp</strong>. For barley straw, the<br />

optimal fit was obtained using nE=0. The Norway spruce had the highest Ec/ρc value<br />

(27.5 GPa/(g/cm 3 )) due to the very low density <strong>of</strong> wood (0.4 g/cm 3 ) compared with <strong>hemp</strong><br />

<strong>fibre</strong>s and glass <strong>fibre</strong>s.<br />

Table 10. Composite and <strong>fibre</strong> strength and stiffness compared to the density. Data are<br />

based on the highest obtained <strong>fibre</strong> content Vf,obt for <strong>composites</strong> and on <strong>fibre</strong>s.<br />

Fibre type and<br />

defibration<br />

ρc<br />

g/cm 3<br />

σcu<br />

MPa<br />

Εc<br />

GPa<br />

σcu/ρc<br />

10 3 m 2 /s 2<br />

Εc/ρc<br />

10 6 m 2 /s 2<br />

σfu/ρf<br />

10 3 m 2 /s 2<br />

Εf/ρf<br />

10 6 m 2 /s 2<br />

Epoxy matrix 1.136 64 2.93 56 2.6 - -<br />

Raw <strong>hemp</strong> bast 1.18 122 20.4 104 17.4 339 49.4<br />

Water retted <strong>hemp</strong> 1.19 153 26.4 129 22.2 370 55.7<br />

C. sub. tr. <strong>hemp</strong> 1.22 130 24.3 107 19.9 340 55.7<br />

P. rad. tr. <strong>hemp</strong> 1.22 174 30.1 143 24.7 407 59.5<br />

Hemp yarn 1.23 230 21.3 187 17.3 428 38.6<br />

Barley straw 3<br />

0.67 19 4.0 28 6.0 160 14.7<br />

E-glass 1.96 769 41.5 392 21.1 509 29.4<br />

Norway spruce 1<br />

0.40 88 11 220 27.5 220 27.5<br />

1: Mechanical properties for dry Norway spruce (Picea abies), with a bulk density <strong>of</strong> 0.40 g/cm 3 and a<br />

cell wall density <strong>of</strong> 1.50 g/cm 3 after correction <strong>of</strong> the bulk tensile strength (88 MPa) and stiffness (11<br />

GPa) for porosity (Boutelje and Rydell, 1986; Klinke et al., 2001).<br />

62 Risø-PhD-11