Properties of hemp fibre polymer composites -An optimisation of ...

Properties of hemp fibre polymer composites -An optimisation of ...

Properties of hemp fibre polymer composites -An optimisation of ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

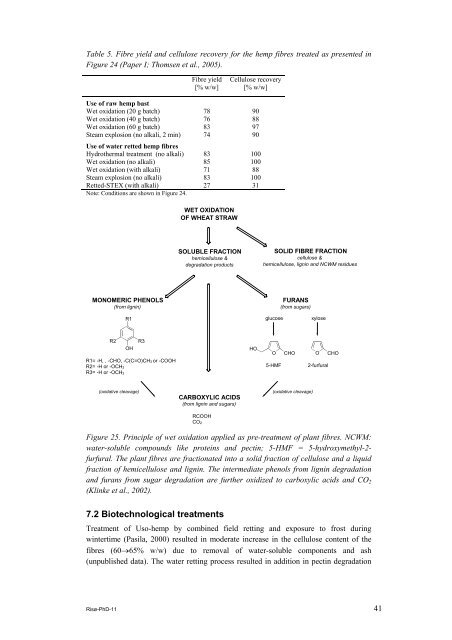

Table 5. Fibre yield and cellulose recovery for the <strong>hemp</strong> <strong>fibre</strong>s treated as presented in<br />

Figure 24 (Paper I; Thomsen et al., 2005).<br />

Fibre yield<br />

[% w/w]<br />

Cellulose recovery<br />

[% w/w]<br />

Use <strong>of</strong> raw <strong>hemp</strong> bast<br />

Wet oxidation (20 g batch) 78 90<br />

Wet oxidation (40 g batch) 76 88<br />

Wet oxidation (60 g batch) 83 97<br />

Steam explosion (no alkali, 2 min) 74 90<br />

Use <strong>of</strong> water retted <strong>hemp</strong> <strong>fibre</strong>s<br />

Hydrothermal treatment (no alkali) 83 100<br />

Wet oxidation (no alkali) 85 100<br />

Wet oxidation (with alkali) 71 88<br />

Steam explosion (no alkali) 83 100<br />

Retted-STEX (with alkali) 27 31<br />

Note: Conditions are shown in Figure 24.<br />

MONOMERIC PHENOLS<br />

(from lignin)<br />

R2<br />

R1<br />

OH<br />

R3<br />

R1= -H, , -CHO, -C(C=O)CH3 or -COOH<br />

R2= -H or -OCH3<br />

R3= -H or -OCH3<br />

(oxidative cleavage)<br />

WET OXIDATION<br />

OF WHEAT STRAW<br />

SOLUBLE FRACTION<br />

hemicellulose &<br />

degradation products<br />

CARBOXYLIC ACIDS<br />

(from lignin and sugars)<br />

RCOOH<br />

CO2<br />

HO<br />

SOLID FIBRE FRACTION<br />

cellulose &<br />

hemicellulose, lignin and NCWM residues<br />

FURANS<br />

(from sugars)<br />

glucose xylose<br />

O CHO<br />

(oxidative cleavage)<br />

O CHO<br />

5-HMF 2-furfural<br />

Figure 25. Principle <strong>of</strong> wet oxidation applied as pre-treatment <strong>of</strong> plant <strong>fibre</strong>s. NCWM:<br />

water-soluble compounds like proteins and pectin; 5-HMF = 5-hydroxymethyl-2furfural.<br />

The plant <strong>fibre</strong>s are fractionated into a solid fraction <strong>of</strong> cellulose and a liquid<br />

fraction <strong>of</strong> hemicellulose and lignin. The intermediate phenols from lignin degradation<br />

and furans from sugar degradation are further oxidized to carboxylic acids and CO2<br />

(Klinke et al., 2002).<br />

7.2 Biotechnological treatments<br />

Treatment <strong>of</strong> Uso-<strong>hemp</strong> by combined field retting and exposure to frost during<br />

wintertime (Pasila, 2000) resulted in moderate increase in the cellulose content <strong>of</strong> the<br />

<strong>fibre</strong>s (60→65% w/w) due to removal <strong>of</strong> water-soluble components and ash<br />

(unpublished data). The water retting process resulted in addition in pectin degradation<br />

Risø-PhD-11 41