Properties of hemp fibre polymer composites -An optimisation of ...

Properties of hemp fibre polymer composites -An optimisation of ...

Properties of hemp fibre polymer composites -An optimisation of ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

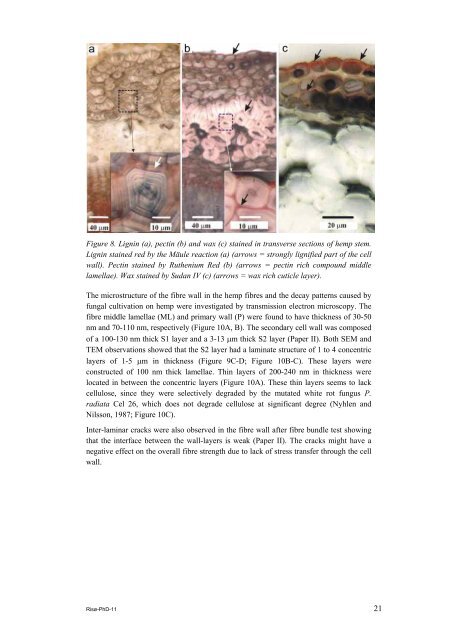

Figure 8. Lignin (a), pectin (b) and wax (c) stained in transverse sections <strong>of</strong> <strong>hemp</strong> stem.<br />

Lignin stained red by the Mäule reaction (a) (arrows = strongly lignified part <strong>of</strong> the cell<br />

wall). Pectin stained by Ruthenium Red (b) (arrows = pectin rich compound middle<br />

lamellae). Wax stained by Sudan IV (c) (arrows = wax rich cuticle layer).<br />

The microstructure <strong>of</strong> the <strong>fibre</strong> wall in the <strong>hemp</strong> <strong>fibre</strong>s and the decay patterns caused by<br />

fungal cultivation on <strong>hemp</strong> were investigated by transmission electron microscopy. The<br />

<strong>fibre</strong> middle lamellae (ML) and primary wall (P) were found to have thickness <strong>of</strong> 30-50<br />

nm and 70-110 nm, respectively (Figure 10A, B). The secondary cell wall was composed<br />

<strong>of</strong> a 100-130 nm thick S1 layer and a 3-13 μm thick S2 layer (Paper II). Both SEM and<br />

TEM observations showed that the S2 layer had a laminate structure <strong>of</strong> 1 to 4 concentric<br />

layers <strong>of</strong> 1-5 μm in thickness (Figure 9C-D; Figure 10B-C). These layers were<br />

constructed <strong>of</strong> 100 nm thick lamellae. Thin layers <strong>of</strong> 200-240 nm in thickness were<br />

located in between the concentric layers (Figure 10A). These thin layers seems to lack<br />

cellulose, since they were selectively degraded by the mutated white rot fungus P.<br />

radiata Cel 26, which does not degrade cellulose at significant degree (Nyhlen and<br />

Nilsson, 1987; Figure 10C).<br />

Inter-laminar cracks were also observed in the <strong>fibre</strong> wall after <strong>fibre</strong> bundle test showing<br />

that the interface between the wall-layers is weak (Paper II). The cracks might have a<br />

negative effect on the overall <strong>fibre</strong> strength due to lack <strong>of</strong> stress transfer through the cell<br />

wall.<br />

Risø-PhD-11 21