Properties of hemp fibre polymer composites -An optimisation of ...

Properties of hemp fibre polymer composites -An optimisation of ...

Properties of hemp fibre polymer composites -An optimisation of ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

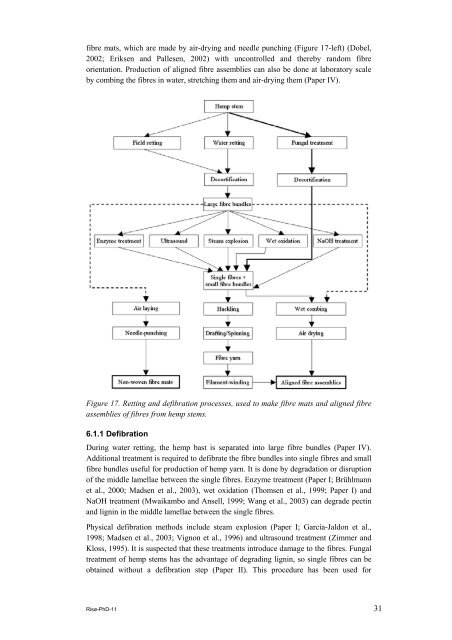

<strong>fibre</strong> mats, which are made by air-drying and needle punching (Figure 17-left) (Dobel,<br />

2002; Eriksen and Pallesen, 2002) with uncontrolled and thereby random <strong>fibre</strong><br />

orientation. Production <strong>of</strong> aligned <strong>fibre</strong> assemblies can also be done at laboratory scale<br />

by combing the <strong>fibre</strong>s in water, stretching them and air-drying them (Paper IV).<br />

Figure 17. Retting and defibration processes, used to make <strong>fibre</strong> mats and aligned <strong>fibre</strong><br />

assemblies <strong>of</strong> <strong>fibre</strong>s from <strong>hemp</strong> stems.<br />

6.1.1 Defibration<br />

During water retting, the <strong>hemp</strong> bast is separated into large <strong>fibre</strong> bundles (Paper IV).<br />

Additional treatment is required to defibrate the <strong>fibre</strong> bundles into single <strong>fibre</strong>s and small<br />

<strong>fibre</strong> bundles useful for production <strong>of</strong> <strong>hemp</strong> yarn. It is done by degradation or disruption<br />

<strong>of</strong> the middle lamellae between the single <strong>fibre</strong>s. Enzyme treatment (Paper I; Brühlmann<br />

et al., 2000; Madsen et al., 2003), wet oxidation (Thomsen et al., 1999; Paper I) and<br />

NaOH treatment (Mwaikambo and <strong>An</strong>sell, 1999; Wang et al., 2003) can degrade pectin<br />

and lignin in the middle lamellae between the single <strong>fibre</strong>s.<br />

Physical defibration methods include steam explosion (Paper I; Garcia-Jaldon et al.,<br />

1998; Madsen et al., 2003; Vignon et al., 1996) and ultrasound treatment (Zimmer and<br />

Kloss, 1995). It is suspected that these treatments introduce damage to the <strong>fibre</strong>s. Fungal<br />

treatment <strong>of</strong> <strong>hemp</strong> stems has the advantage <strong>of</strong> degrading lignin, so single <strong>fibre</strong>s can be<br />

obtained without a defibration step (Paper II). This procedure has been used for<br />

Risø-PhD-11 31