Properties of hemp fibre polymer composites -An optimisation of ...

Properties of hemp fibre polymer composites -An optimisation of ...

Properties of hemp fibre polymer composites -An optimisation of ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

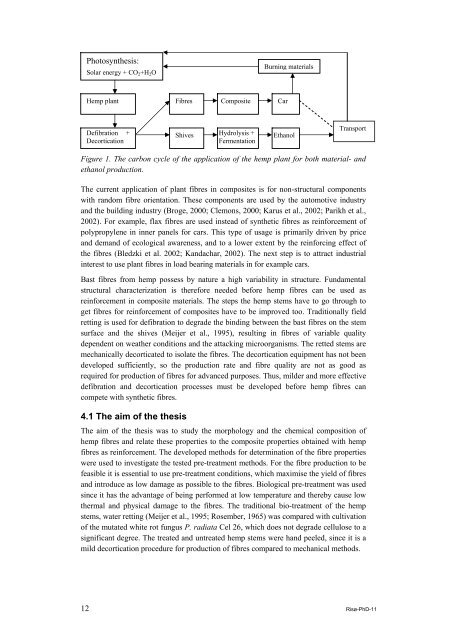

Photosynthesis:<br />

Solar energy + CO2+H2O Hemp plant Fibres<br />

Defibration +<br />

Decortication<br />

Shives<br />

Composite<br />

Hydrolysis +<br />

Fermentation<br />

Burning materials<br />

Car<br />

Ethanol<br />

Transport<br />

Figure 1. The carbon cycle <strong>of</strong> the application <strong>of</strong> the <strong>hemp</strong> plant for both material- and<br />

ethanol production.<br />

The current application <strong>of</strong> plant <strong>fibre</strong>s in <strong>composites</strong> is for non-structural components<br />

with random <strong>fibre</strong> orientation. These components are used by the automotive industry<br />

and the building industry (Broge, 2000; Clemons, 2000; Karus et al., 2002; Parikh et al.,<br />

2002). For example, flax <strong>fibre</strong>s are used instead <strong>of</strong> synthetic <strong>fibre</strong>s as reinforcement <strong>of</strong><br />

polypropylene in inner panels for cars. This type <strong>of</strong> usage is primarily driven by price<br />

and demand <strong>of</strong> ecological awareness, and to a lower extent by the reinforcing effect <strong>of</strong><br />

the <strong>fibre</strong>s (Bledzki et al. 2002; Kandachar, 2002). The next step is to attract industrial<br />

interest to use plant <strong>fibre</strong>s in load bearing materials in for example cars.<br />

Bast <strong>fibre</strong>s from <strong>hemp</strong> possess by nature a high variability in structure. Fundamental<br />

structural characterization is therefore needed before <strong>hemp</strong> <strong>fibre</strong>s can be used as<br />

reinforcement in composite materials. The steps the <strong>hemp</strong> stems have to go through to<br />

get <strong>fibre</strong>s for reinforcement <strong>of</strong> <strong>composites</strong> have to be improved too. Traditionally field<br />

retting is used for defibration to degrade the binding between the bast <strong>fibre</strong>s on the stem<br />

surface and the shives (Meijer et al., 1995), resulting in <strong>fibre</strong>s <strong>of</strong> variable quality<br />

dependent on weather conditions and the attacking microorganisms. The retted stems are<br />

mechanically decorticated to isolate the <strong>fibre</strong>s. The decortication equipment has not been<br />

developed sufficiently, so the production rate and <strong>fibre</strong> quality are not as good as<br />

required for production <strong>of</strong> <strong>fibre</strong>s for advanced purposes. Thus, milder and more effective<br />

defibration and decortication processes must be developed before <strong>hemp</strong> <strong>fibre</strong>s can<br />

compete with synthetic <strong>fibre</strong>s.<br />

4.1 The aim <strong>of</strong> the thesis<br />

The aim <strong>of</strong> the thesis was to study the morphology and the chemical composition <strong>of</strong><br />

<strong>hemp</strong> <strong>fibre</strong>s and relate these properties to the composite properties obtained with <strong>hemp</strong><br />

<strong>fibre</strong>s as reinforcement. The developed methods for determination <strong>of</strong> the <strong>fibre</strong> properties<br />

were used to investigate the tested pre-treatment methods. For the <strong>fibre</strong> production to be<br />

feasible it is essential to use pre-treatment conditions, which maximise the yield <strong>of</strong> <strong>fibre</strong>s<br />

and introduce as low damage as possible to the <strong>fibre</strong>s. Biological pre-treatment was used<br />

since it has the advantage <strong>of</strong> being performed at low temperature and thereby cause low<br />

thermal and physical damage to the <strong>fibre</strong>s. The traditional bio-treatment <strong>of</strong> the <strong>hemp</strong><br />

stems, water retting (Meijer et al., 1995; Rosember, 1965) was compared with cultivation<br />

<strong>of</strong> the mutated white rot fungus P. radiata Cel 26, which does not degrade cellulose to a<br />

significant degree. The treated and untreated <strong>hemp</strong> stems were hand peeled, since it is a<br />

mild decortication procedure for production <strong>of</strong> <strong>fibre</strong>s compared to mechanical methods.<br />

12 Risø-PhD-11