Properties of hemp fibre polymer composites -An optimisation of ...

Properties of hemp fibre polymer composites -An optimisation of ...

Properties of hemp fibre polymer composites -An optimisation of ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

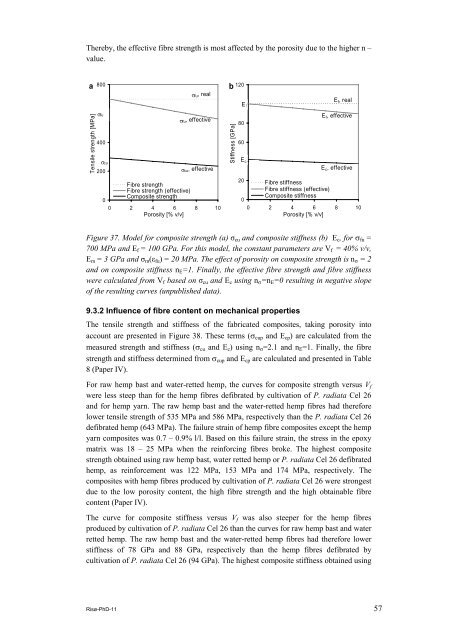

Thereby, the effective <strong>fibre</strong> strength is most affected by the porosity due to the higher n –<br />

value.<br />

a<br />

Tensile strength [MPa]<br />

800<br />

600 σfu<br />

400<br />

σcu<br />

200<br />

σfu, real<br />

σfu, effective<br />

σcu, effective<br />

0<br />

Fibre strength<br />

Fibre strength (effective)<br />

Composite strength<br />

0 2 4 6 8 10<br />

Porosity [% v/v]<br />

b<br />

Stiffness [GPa]<br />

120<br />

100E<br />

f<br />

80<br />

60<br />

40 Ec E f, real<br />

E f, effective<br />

E c, effective<br />

20 Fibre stiffness<br />

Fibre stiffness (effective)<br />

0<br />

Composite stiffness<br />

0 2 4 6 8 10<br />

Porosity [% v/v]<br />

Figure 37. Model for composite strength (a) σcu and composite stiffness (b) Ec, for σfu =<br />

700 MPa and Ef = 100 GPa. For this model, the constant parameters are Vf = 40% v/v,<br />

Em = 3 GPa and σm(εfu) = 20 MPa. The effect <strong>of</strong> porosity on composite strength is nσ = 2<br />

and on composite stiffness nE=1. Finally, the effective <strong>fibre</strong> strength and <strong>fibre</strong> stiffness<br />

were calculated from Vf based on σcu and Ec using nσ=nE=0 resulting in negative slope<br />

<strong>of</strong> the resulting curves (unpublished data).<br />

9.3.2 Influence <strong>of</strong> <strong>fibre</strong> content on mechanical properties<br />

The tensile strength and stiffness <strong>of</strong> the fabricated <strong>composites</strong>, taking porosity into<br />

account are presented in Figure 38. These terms (σcup and Ecp) are calculated from the<br />

measured strength and stiffness (σcu and Ec) using nσ=2.1 and nE=1. Finally, the <strong>fibre</strong><br />

strength and stiffness determined from σcup and Ecp are calculated and presented in Table<br />

8 (Paper IV).<br />

For raw <strong>hemp</strong> bast and water-retted <strong>hemp</strong>, the curves for composite strength versus Vf<br />

were less steep than for the <strong>hemp</strong> <strong>fibre</strong>s defibrated by cultivation <strong>of</strong> P. radiata Cel 26<br />

and for <strong>hemp</strong> yarn. The raw <strong>hemp</strong> bast and the water-retted <strong>hemp</strong> <strong>fibre</strong>s had therefore<br />

lower tensile strength <strong>of</strong> 535 MPa and 586 MPa, respectively than the P. radiata Cel 26<br />

defibrated <strong>hemp</strong> (643 MPa). The failure strain <strong>of</strong> <strong>hemp</strong> <strong>fibre</strong> <strong>composites</strong> except the <strong>hemp</strong><br />

yarn <strong>composites</strong> was 0.7 – 0.9% l/l. Based on this failure strain, the stress in the epoxy<br />

matrix was 18 – 25 MPa when the reinforcing <strong>fibre</strong>s broke. The highest composite<br />

strength obtained using raw <strong>hemp</strong> bast, water retted <strong>hemp</strong> or P. radiata Cel 26 defibrated<br />

<strong>hemp</strong>, as reinforcement was 122 MPa, 153 MPa and 174 MPa, respectively. The<br />

<strong>composites</strong> with <strong>hemp</strong> <strong>fibre</strong>s produced by cultivation <strong>of</strong> P. radiata Cel 26 were strongest<br />

due to the low porosity content, the high <strong>fibre</strong> strength and the high obtainable <strong>fibre</strong><br />

content (Paper IV).<br />

The curve for composite stiffness versus Vf was also steeper for the <strong>hemp</strong> <strong>fibre</strong>s<br />

produced by cultivation <strong>of</strong> P. radiata Cel 26 than the curves for raw <strong>hemp</strong> bast and water<br />

retted <strong>hemp</strong>. The raw <strong>hemp</strong> bast and the water-retted <strong>hemp</strong> <strong>fibre</strong>s had therefore lower<br />

stiffness <strong>of</strong> 78 GPa and 88 GPa, respectively than the <strong>hemp</strong> <strong>fibre</strong>s defibrated by<br />

cultivation <strong>of</strong> P. radiata Cel 26 (94 GPa). The highest composite stiffness obtained using<br />

Risø-PhD-11 57