Properties of hemp fibre polymer composites -An optimisation of ...

Properties of hemp fibre polymer composites -An optimisation of ...

Properties of hemp fibre polymer composites -An optimisation of ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

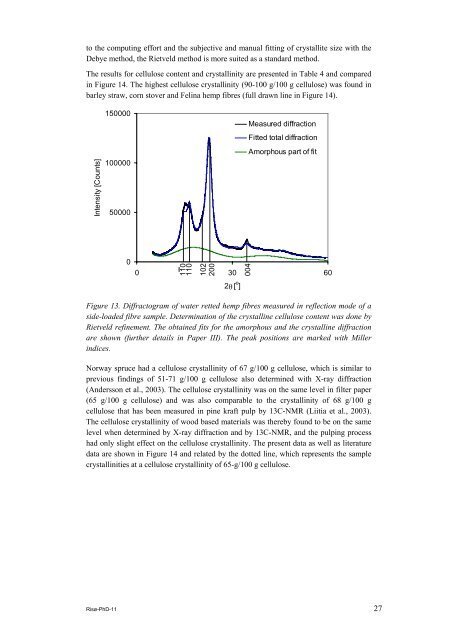

to the computing effort and the subjective and manual fitting <strong>of</strong> crystallite size with the<br />

Debye method, the Rietveld method is more suited as a standard method.<br />

The results for cellulose content and crystallinity are presented in Table 4 and compared<br />

in Figure 14. The highest cellulose crystallinity (90-100 g/100 g cellulose) was found in<br />

barley straw, corn stover and Felina <strong>hemp</strong> <strong>fibre</strong>s (full drawn line in Figure 14).<br />

Intensity [Counts]..<br />

150000<br />

100000<br />

50000<br />

0<br />

110<br />

110<br />

102<br />

200<br />

0 30<br />

2θ [ o ]<br />

004<br />

Measured diffraction<br />

Fitted total diffraction<br />

Amorphous part <strong>of</strong> fit<br />

Figure 13. Diffractogram <strong>of</strong> water retted <strong>hemp</strong> <strong>fibre</strong>s measured in reflection mode <strong>of</strong> a<br />

side-loaded <strong>fibre</strong> sample. Determination <strong>of</strong> the crystalline cellulose content was done by<br />

Rietveld refinement. The obtained fits for the amorphous and the crystalline diffraction<br />

are shown (further details in Paper III). The peak positions are marked with Miller<br />

indices.<br />

Norway spruce had a cellulose crystallinity <strong>of</strong> 67 g/100 g cellulose, which is similar to<br />

previous findings <strong>of</strong> 51-71 g/100 g cellulose also determined with X-ray diffraction<br />

(<strong>An</strong>dersson et al., 2003). The cellulose crystallinity was on the same level in filter paper<br />

(65 g/100 g cellulose) and was also comparable to the crystallinity <strong>of</strong> 68 g/100 g<br />

cellulose that has been measured in pine kraft pulp by 13C-NMR (Liitia et al., 2003).<br />

The cellulose crystallinity <strong>of</strong> wood based materials was thereby found to be on the same<br />

level when determined by X-ray diffraction and by 13C-NMR, and the pulping process<br />

had only slight effect on the cellulose crystallinity. The present data as well as literature<br />

data are shown in Figure 14 and related by the dotted line, which represents the sample<br />

crystallinities at a cellulose crystallinity <strong>of</strong> 65-g/100 g cellulose.<br />

Risø-PhD-11 27<br />

60