Properties of hemp fibre polymer composites -An optimisation of ...

Properties of hemp fibre polymer composites -An optimisation of ...

Properties of hemp fibre polymer composites -An optimisation of ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

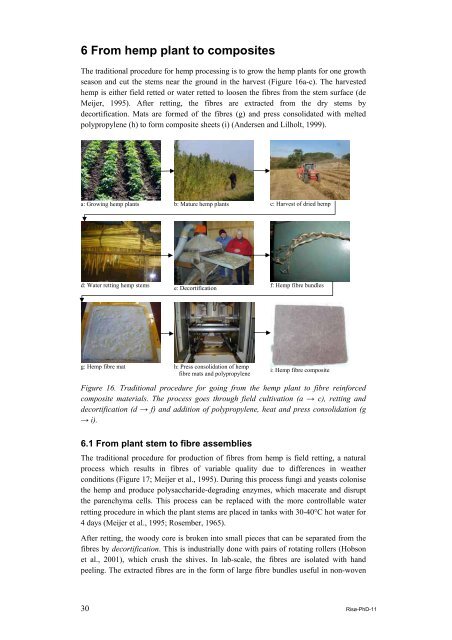

6 From <strong>hemp</strong> plant to <strong>composites</strong><br />

The traditional procedure for <strong>hemp</strong> processing is to grow the <strong>hemp</strong> plants for one growth<br />

season and cut the stems near the ground in the harvest (Figure 16a-c). The harvested<br />

<strong>hemp</strong> is either field retted or water retted to loosen the <strong>fibre</strong>s from the stem surface (de<br />

Meijer, 1995). After retting, the <strong>fibre</strong>s are extracted from the dry stems by<br />

decortification. Mats are formed <strong>of</strong> the <strong>fibre</strong>s (g) and press consolidated with melted<br />

polypropylene (h) to form composite sheets (i) (<strong>An</strong>dersen and Lilholt, 1999).<br />

a: Growing <strong>hemp</strong> plants<br />

d: Water retting <strong>hemp</strong> stems<br />

g: Hemp <strong>fibre</strong> mat<br />

b: Mature <strong>hemp</strong> plants<br />

e: Decortification<br />

h: Press consolidation <strong>of</strong> <strong>hemp</strong><br />

i: <strong>fibre</strong> mats and polypropylene<br />

c: Harvest <strong>of</strong> dried <strong>hemp</strong><br />

f: Hemp <strong>fibre</strong> bundles<br />

i: Hemp <strong>fibre</strong> composite<br />

Figure 16. Traditional procedure for going from the <strong>hemp</strong> plant to <strong>fibre</strong> reinforced<br />

composite materials. The process goes through field cultivation (a → c), retting and<br />

decortification (d → f) and addition <strong>of</strong> polypropylene, heat and press consolidation (g<br />

→ i).<br />

6.1 From plant stem to <strong>fibre</strong> assemblies<br />

The traditional procedure for production <strong>of</strong> <strong>fibre</strong>s from <strong>hemp</strong> is field retting, a natural<br />

process which results in <strong>fibre</strong>s <strong>of</strong> variable quality due to differences in weather<br />

conditions (Figure 17; Meijer et al., 1995). During this process fungi and yeasts colonise<br />

the <strong>hemp</strong> and produce polysaccharide-degrading enzymes, which macerate and disrupt<br />

the parenchyma cells. This process can be replaced with the more controllable water<br />

retting procedure in which the plant stems are placed in tanks with 30-40°C hot water for<br />

4 days (Meijer et al., 1995; Rosember, 1965).<br />

After retting, the woody core is broken into small pieces that can be separated from the<br />

<strong>fibre</strong>s by decortification. This is industrially done with pairs <strong>of</strong> rotating rollers (Hobson<br />

et al., 2001), which crush the shives. In lab-scale, the <strong>fibre</strong>s are isolated with hand<br />

peeling. The extracted <strong>fibre</strong>s are in the form <strong>of</strong> large <strong>fibre</strong> bundles useful in non-woven<br />

30 Risø-PhD-11