Properties of hemp fibre polymer composites -An optimisation of ...

Properties of hemp fibre polymer composites -An optimisation of ...

Properties of hemp fibre polymer composites -An optimisation of ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

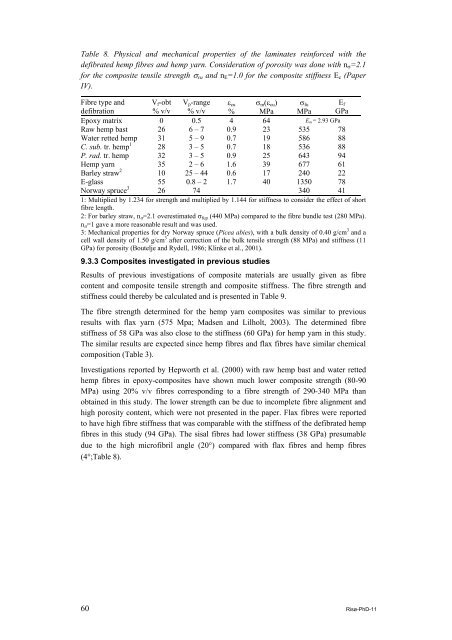

Table 8. Physical and mechanical properties <strong>of</strong> the laminates reinforced with the<br />

defibrated <strong>hemp</strong> <strong>fibre</strong>s and <strong>hemp</strong> yarn. Consideration <strong>of</strong> porosity was done with nσ=2.1<br />

for the composite tensile strength σcu and nE=1.0 for the composite stiffness Ec (Paper<br />

IV).<br />

Fibre type and<br />

defibration<br />

Vf-obt<br />

% v/v<br />

Vp-range<br />

% v/v<br />

εcu<br />

%<br />

σm(εcu)<br />

MPa<br />

σfu<br />

MPa<br />

Ef<br />

GPa<br />

Epoxy matrix 0 0.5 4 64 Em = 2.93 GPa<br />

Raw <strong>hemp</strong> bast 26 6 – 7 0.9 23 535 78<br />

Water retted <strong>hemp</strong> 31 5 – 9 0.7 19 586 88<br />

C. sub. tr. <strong>hemp</strong> 1<br />

28 3 – 5 0.7 18 536 88<br />

P. rad. tr. <strong>hemp</strong> 32 3 – 5 0.9 25 643 94<br />

Hemp yarn 35 2 – 6 1.6 39 677 61<br />

Barley straw 2<br />

10 25 – 44 0.6 17 240 22<br />

E-glass 55 0.8 – 2 1.7 40 1350 78<br />

Norway spruce 3<br />

26 74 340 41<br />

1: Multiplied by 1.234 for strength and multiplied by 1.144 for stiffness to consider the effect <strong>of</strong> short<br />

<strong>fibre</strong> length.<br />

2: For barley straw, nσ=2.1 overestimated σfup (440 MPa) compared to the <strong>fibre</strong> bundle test (280 MPa).<br />

nσ=1 gave a more reasonable result and was used.<br />

3: Mechanical properties for dry Norway spruce (Picea abies), with a bulk density <strong>of</strong> 0.40 g/cm 3 and a<br />

cell wall density <strong>of</strong> 1.50 g/cm 3 after correction <strong>of</strong> the bulk tensile strength (88 MPa) and stiffness (11<br />

GPa) for porosity (Boutelje and Rydell, 1986; Klinke et al., 2001).<br />

9.3.3 Composites investigated in previous studies<br />

Results <strong>of</strong> previous investigations <strong>of</strong> composite materials are usually given as <strong>fibre</strong><br />

content and composite tensile strength and composite stiffness. The <strong>fibre</strong> strength and<br />

stiffness could thereby be calculated and is presented in Table 9.<br />

The <strong>fibre</strong> strength determined for the <strong>hemp</strong> yarn <strong>composites</strong> was similar to previous<br />

results with flax yarn (575 Mpa; Madsen and Lilholt, 2003). The determined <strong>fibre</strong><br />

stiffness <strong>of</strong> 58 GPa was also close to the stiffness (60 GPa) for <strong>hemp</strong> yarn in this study.<br />

The similar results are expected since <strong>hemp</strong> <strong>fibre</strong>s and flax <strong>fibre</strong>s have similar chemical<br />

composition (Table 3).<br />

Investigations reported by Hepworth et al. (2000) with raw <strong>hemp</strong> bast and water retted<br />

<strong>hemp</strong> <strong>fibre</strong>s in epoxy-<strong>composites</strong> have shown much lower composite strength (80-90<br />

MPa) using 20% v/v <strong>fibre</strong>s corresponding to a <strong>fibre</strong> strength <strong>of</strong> 290-340 MPa than<br />

obtained in this study. The lower strength can be due to incomplete <strong>fibre</strong> alignment and<br />

high porosity content, which were not presented in the paper. Flax <strong>fibre</strong>s were reported<br />

to have high <strong>fibre</strong> stiffness that was comparable with the stiffness <strong>of</strong> the defibrated <strong>hemp</strong><br />

<strong>fibre</strong>s in this study (94 GPa). The sisal <strong>fibre</strong>s had lower stiffness (38 GPa) presumable<br />

due to the high micr<strong>of</strong>ibril angle (20°) compared with flax <strong>fibre</strong>s and <strong>hemp</strong> <strong>fibre</strong>s<br />

(4°;Table 8).<br />

60 Risø-PhD-11