Properties of hemp fibre polymer composites -An optimisation of ...

Properties of hemp fibre polymer composites -An optimisation of ...

Properties of hemp fibre polymer composites -An optimisation of ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

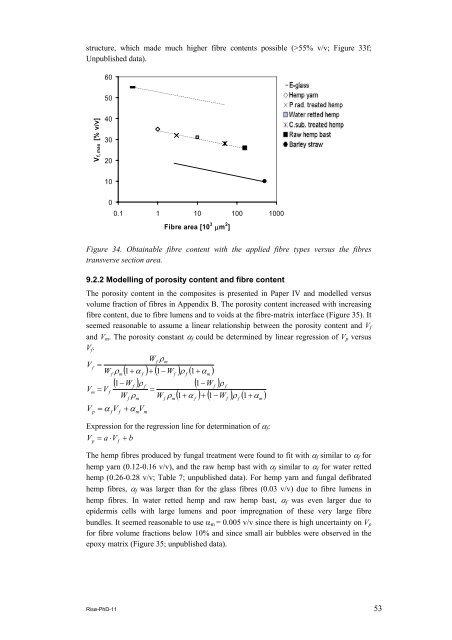

structure, which made much higher <strong>fibre</strong> contents possible (>55% v/v; Figure 33f;<br />

Unpublished data).<br />

Vf, max [% v/v]<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

0.1 1 10 100 1000<br />

Fibre area [10 3 μm 2 ]<br />

Figure 34. Obtainable <strong>fibre</strong> content with the applied <strong>fibre</strong> types versus the <strong>fibre</strong>s<br />

transverse section area.<br />

9.2.2 Modelling <strong>of</strong> porosity content and <strong>fibre</strong> content<br />

The porosity content in the <strong>composites</strong> is presented in Paper IV and modelled versus<br />

volume fraction <strong>of</strong> <strong>fibre</strong>s in Appendix B. The porosity content increased with increasing<br />

<strong>fibre</strong> content, due to <strong>fibre</strong> lumens and to voids at the <strong>fibre</strong>-matrix interface (Figure 35). It<br />

seemed reasonable to assume a linear relationship between the porosity content and Vf<br />

and Vm. The porosity constant αf could be determined by linear regression <strong>of</strong> Vp versus<br />

Vf.<br />

Wf<br />

ρm<br />

V f =<br />

Wf<br />

ρm<br />

( 1+<br />

α f ) + ( 1−<br />

Wf<br />

) ρ f ( 1+<br />

αm<br />

)<br />

( 1−<br />

W f ) ρ f<br />

( 1−<br />

W f ) ρ f<br />

Vm<br />

= V f =<br />

W f ρm<br />

W f ρm<br />

( 1+<br />

α f ) + ( 1−<br />

Wf<br />

) ρ f ( 1+<br />

αm<br />

)<br />

V = α V + α V<br />

p<br />

f<br />

f<br />

m<br />

m<br />

Expression for the regression line for determination <strong>of</strong> αf:<br />

= a ⋅V<br />

+ b<br />

Vp f<br />

The <strong>hemp</strong> <strong>fibre</strong>s produced by fungal treatment were found to fit with αf similar to αf for<br />

<strong>hemp</strong> yarn (0.12-0.16 v/v), and the raw <strong>hemp</strong> bast with αf similar to αf for water retted<br />

<strong>hemp</strong> (0.26-0.28 v/v; Table 7; unpublished data). For <strong>hemp</strong> yarn and fungal defibrated<br />

<strong>hemp</strong> <strong>fibre</strong>s, αf was larger than for the glass <strong>fibre</strong>s (0.03 v/v) due to <strong>fibre</strong> lumens in<br />

<strong>hemp</strong> <strong>fibre</strong>s. In water retted <strong>hemp</strong> and raw <strong>hemp</strong> bast, αf was even larger due to<br />

epidermis cells with large lumens and poor impregnation <strong>of</strong> these very large <strong>fibre</strong><br />

bundles. It seemed reasonable to use αm = 0.005 v/v since there is high uncertainty on Vp<br />

for <strong>fibre</strong> volume fractions below 10% and since small air bubbles were observed in the<br />

epoxy matrix (Figure 35; unpublished data).<br />

Risø-PhD-11 53