Properties of hemp fibre polymer composites -An optimisation of ...

Properties of hemp fibre polymer composites -An optimisation of ...

Properties of hemp fibre polymer composites -An optimisation of ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

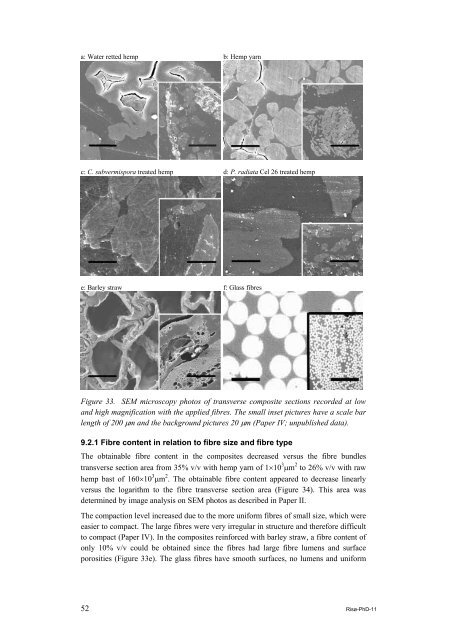

a: Water retted <strong>hemp</strong> b: Hemp yarn<br />

c: C. subvermispora treated <strong>hemp</strong><br />

e: Barley straw<br />

d: P. radiata Cel 26 treated <strong>hemp</strong><br />

f: Glass <strong>fibre</strong>s<br />

Figure 33. SEM microscopy photos <strong>of</strong> transverse composite sections recorded at low<br />

and high magnification with the applied <strong>fibre</strong>s. The small inset pictures have a scale bar<br />

length <strong>of</strong> 200 μm and the background pictures 20 μm (Paper IV; unpublished data).<br />

9.2.1 Fibre content in relation to <strong>fibre</strong> size and <strong>fibre</strong> type<br />

The obtainable <strong>fibre</strong> content in the <strong>composites</strong> decreased versus the <strong>fibre</strong> bundles<br />

transverse section area from 35% v/v with <strong>hemp</strong> yarn <strong>of</strong> 1×10 3 μm 2 to 26% v/v with raw<br />

<strong>hemp</strong> bast <strong>of</strong> 160×10 3 μm 2 . The obtainable <strong>fibre</strong> content appeared to decrease linearly<br />

versus the logarithm to the <strong>fibre</strong> transverse section area (Figure 34). This area was<br />

determined by image analysis on SEM photos as described in Paper II.<br />

The compaction level increased due to the more uniform <strong>fibre</strong>s <strong>of</strong> small size, which were<br />

easier to compact. The large <strong>fibre</strong>s were very irregular in structure and therefore difficult<br />

to compact (Paper IV). In the <strong>composites</strong> reinforced with barley straw, a <strong>fibre</strong> content <strong>of</strong><br />

only 10% v/v could be obtained since the <strong>fibre</strong>s had large <strong>fibre</strong> lumens and surface<br />

porosities (Figure 33e). The glass <strong>fibre</strong>s have smooth surfaces, no lumens and uniform<br />

52 Risø-PhD-11