Properties of hemp fibre polymer composites -An optimisation of ...

Properties of hemp fibre polymer composites -An optimisation of ...

Properties of hemp fibre polymer composites -An optimisation of ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

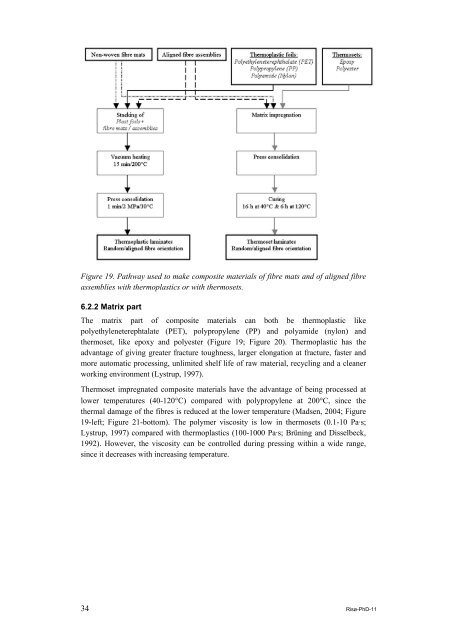

Figure 19. Pathway used to make composite materials <strong>of</strong> <strong>fibre</strong> mats and <strong>of</strong> aligned <strong>fibre</strong><br />

assemblies with thermoplastics or with thermosets.<br />

6.2.2 Matrix part<br />

The matrix part <strong>of</strong> composite materials can both be thermoplastic like<br />

polyethyleneterephtalate (PET), polypropylene (PP) and polyamide (nylon) and<br />

thermoset, like epoxy and polyester (Figure 19; Figure 20). Thermoplastic has the<br />

advantage <strong>of</strong> giving greater fracture toughness, larger elongation at fracture, faster and<br />

more automatic processing, unlimited shelf life <strong>of</strong> raw material, recycling and a cleaner<br />

working environment (Lystrup, 1997).<br />

Thermoset impregnated composite materials have the advantage <strong>of</strong> being processed at<br />

lower temperatures (40-120°C) compared with polypropylene at 200°C, since the<br />

thermal damage <strong>of</strong> the <strong>fibre</strong>s is reduced at the lower temperature (Madsen, 2004; Figure<br />

19-left; Figure 21-bottom). The <strong>polymer</strong> viscosity is low in thermosets (0.1-10 Pa·s;<br />

Lystrup, 1997) compared with thermoplastics (100-1000 Pa·s; Brüning and Disselbeck,<br />

1992). However, the viscosity can be controlled during pressing within a wide range,<br />

since it decreases with increasing temperature.<br />

34 Risø-PhD-11