NUI Galway – UL Alliance First Annual ENGINEERING AND - ARAN ...

NUI Galway – UL Alliance First Annual ENGINEERING AND - ARAN ...

NUI Galway – UL Alliance First Annual ENGINEERING AND - ARAN ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

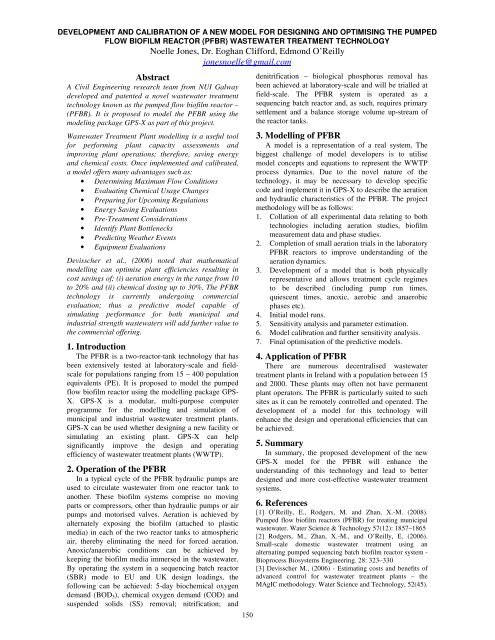

DEVELOPMENT <strong>AND</strong> CALIBRATION OF A NEW MODEL FOR DESIGNING <strong>AND</strong> OPTIMISING THE PUMPED<br />

FLOW BIOFILM REACTOR (PFBR) WASTEWATER TREATMENT TECHNOLOGY<br />

Noelle Jones, Dr. Eoghan Clifford, Edmond O’Reilly<br />

jonesnoelle@gmail.com<br />

Abstract<br />

A Civil Engineering research team from <strong>NUI</strong> <strong>Galway</strong><br />

developed and patented a novel wastewater treatment<br />

technology known as the pumped flow biofilm reactor <strong>–</strong><br />

(PFBR). It is proposed to model the PFBR using the<br />

modeling package GPS-X as part of this project.<br />

Wastewater Treatment Plant modelling is a useful tool<br />

for performing plant capacity assessments and<br />

improving plant operations; therefore, saving energy<br />

and chemical costs. Once implemented and calibrated,<br />

a model offers many advantages such as:<br />

• Determining Maximum Flow Conditions<br />

• Evaluating Chemical Usage Changes<br />

• Preparing for Upcoming Regulations<br />

• Energy Saving Evaluations<br />

• Pre-Treatment Considerations<br />

• Identify Plant Bottlenecks<br />

• Predicting Weather Events<br />

• Equipment Evaluations<br />

Devisscher et al., (2006) noted that mathematical<br />

modelling can optimise plant efficiencies resulting in<br />

cost savings of; (i) aeration energy in the range from 10<br />

to 20% and (ii) chemical dosing up to 30%. The PFBR<br />

technology is currently undergoing commercial<br />

evaluation; thus a predictive model capable of<br />

simulating performance for both municipal and<br />

industrial strength wastewaters will add further value to<br />

the commercial offering.<br />

1. Introduction<br />

The PFBR is a two-reactor-tank technology that has<br />

been extensively tested at laboratory-scale and fieldscale<br />

for populations ranging from 15 <strong>–</strong> 400 population<br />

equivalents (PE). It is proposed to model the pumped<br />

flow biofilm reactor using the modelling package GPS-<br />

X. GPS-X is a modular, multi-purpose computer<br />

programme for the modelling and simulation of<br />

municipal and industrial wastewater treatment plants.<br />

GPS-X can be used whether designing a new facility or<br />

simulating an existing plant. GPS-X can help<br />

significantly improve the design and operating<br />

efficiency of wastewater treatment plants (WWTP).<br />

2. Operation of the PFBR<br />

In a typical cycle of the PFBR hydraulic pumps are<br />

used to circulate wastewater from one reactor tank to<br />

another. These biofilm systems comprise no moving<br />

parts or compressors, other than hydraulic pumps or air<br />

pumps and motorised valves. Aeration is achieved by<br />

alternately exposing the biofilm (attached to plastic<br />

media) in each of the two reactor tanks to atmospheric<br />

air, thereby eliminating the need for forced aeration.<br />

Anoxic/anaerobic conditions can be achieved by<br />

keeping the biofilm media immersed in the wastewater.<br />

By operating the system in a sequencing batch reactor<br />

(SBR) mode to EU and UK design loadings, the<br />

following can be achieved: 5-day biochemical oxygen<br />

demand (BOD5), chemical oxygen demand (COD) and<br />

suspended solids (SS) removal; nitrification; and<br />

150<br />

denitrification <strong>–</strong> biological phosphorus removal has<br />

been achieved at laboratory-scale and will be trialled at<br />

field-scale. The PFBR system is operated as a<br />

sequencing batch reactor and, as such, requires primary<br />

settlement and a balance storage volume up-stream of<br />

the reactor tanks.<br />

3. Modelling of PFBR<br />

A model is a representation of a real system. The<br />

biggest challenge of model developers is to utilise<br />

model concepts and equations to represent the WWTP<br />

process dynamics. Due to the novel nature of the<br />

technology, it may be necessary to develop specific<br />

code and implement it in GPS-X to describe the aeration<br />

and hydraulic characteristics of the PFBR. The project<br />

methodology will be as follows:<br />

1. Collation of all experimental data relating to both<br />

technologies including aeration studies, biofilm<br />

measurement data and phase studies.<br />

2. Completion of small aeration trials in the laboratory<br />

PFBR reactors to improve understanding of the<br />

aeration dynamics.<br />

3. Development of a model that is both physically<br />

representative and allows treatment cycle regimes<br />

to be described (including pump run times,<br />

quiescent times, anoxic, aerobic and anaerobic<br />

phases etc).<br />

4. Initial model runs.<br />

5. Sensitivity analysis and parameter estimation.<br />

6. Model calibration and further sensitivity analysis.<br />

7. Final optimisation of the predictive models.<br />

4. Application of PFBR<br />

There are numerous decentralised wastewater<br />

treatment plants in Ireland with a population between 15<br />

and 2000. These plants may often not have permanent<br />

plant operators. The PFBR is particularly suited to such<br />

sites as it can be remotely controlled and operated. The<br />

development of a model for this technology will<br />

enhance the design and operational efficiencies that can<br />

be achieved.<br />

5. Summary<br />

In summary, the proposed development of the new<br />

GPS-X model for the PFBR will enhance the<br />

understanding of this technology and lead to better<br />

designed and more cost-effective wastewater treatment<br />

systems.<br />

6. References<br />

[1] O’Reilly, E., Rodgers, M. and Zhan, X.-M. (2008).<br />

Pumped flow biofilm reactors (PFBR) for treating municipal<br />

wastewater. Water Science & Technology 57(12): 1857<strong>–</strong>1865<br />

[2] Rodgers, M., Zhan, X.-M., and O’Reilly, E. (2006).<br />

Small-scale domestic wastewater treatment using an<br />

alternating pumped sequencing batch biofilm reactor system -<br />

Bioprocess Biosystems Engineering. 28: 323<strong>–</strong>330<br />

[3] Devisscher M., (2006) - Estimating costs and benefits of<br />

advanced control for wastewater treatment plants <strong>–</strong> the<br />

MAgIC methodology. Water Science and Technology, 52(45).