NUI Galway – UL Alliance First Annual ENGINEERING AND - ARAN ...

NUI Galway – UL Alliance First Annual ENGINEERING AND - ARAN ...

NUI Galway – UL Alliance First Annual ENGINEERING AND - ARAN ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Creep Relaxation and Crack Growth Predictions in 316H Austenitic Steel<br />

under Combined Primary and Secondary Loading<br />

Hamed Yazdani Nezhad and Noel P. O’Dowd<br />

Materials and Surface Science Institute<br />

Department of Mechanical and Aeronautical Engineering<br />

University of Limerick, Limerick, Ireland<br />

E-mail(s): hamed.yazdani-nezhad@ul.ie; noel.odowd@ul.ie<br />

Abstract<br />

Compact tension 316H specimens, extracted from an<br />

as-received ex-service pressure vessel header, have<br />

been pre-compressed to different load levels in order to<br />

introduce a tensile residual stress (RS) field in the<br />

specimens. Finite element (FE) analysis has been<br />

carried out to predict the required loading level.<br />

Residual stress profiles along the crack path are also<br />

compared with those measured using neutron<br />

diffraction (ND) facilities. The creep relaxation<br />

behaviour has been studied numerically and the results<br />

have been compared with the earlier studies.<br />

1. Introduction<br />

Studies of creep behaviour of crucial structures such<br />

as power generation plant are always important in the<br />

category of structural integrity assessment. Type 316Haustenitic<br />

steel is a typical material used in the steam<br />

headers, working at the elevated temperature (550°C).<br />

Several procedures regarding the structural integrity<br />

assessment have been standardized [1,2] and<br />

successfully used to evaluate the effect of defects on<br />

creep behaviour. The effect of tensile RS in 316H<br />

compact tension, C(T), specimens (25mm thickness)<br />

subjected to pre-compression, has been studied in [3].<br />

In this work, however, the combined stress effects on<br />

creep crack growth and relaxation are studied under<br />

different residual stress.<br />

2. Method<br />

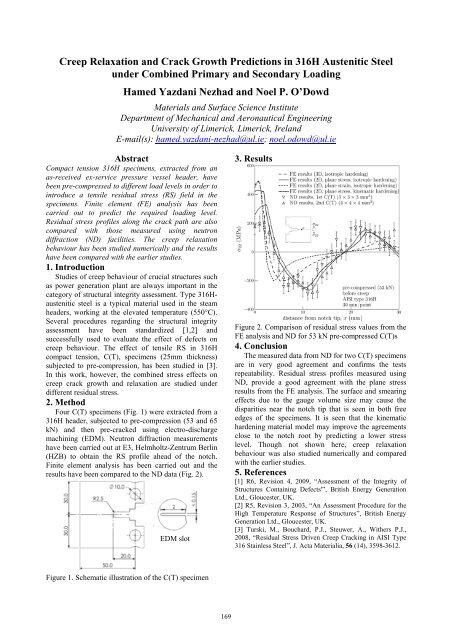

Four C(T) specimens (Fig. 1) were extracted from a<br />

316H header, subjected to pre-compression (53 and 65<br />

kN) and then pre-cracked using electro-discharge<br />

machining (EDM). Neutron diffraction measurements<br />

have been carried out at E3, Helmholtz-Zentrum Berlin<br />

(HZB) to obtain the RS profile ahead of the notch.<br />

Finite element analysis has been carried out and the<br />

results have been compared to the ND data (Fig. 2).<br />

EDM slot<br />

Figure 1. Schematic illustration of the C(T) specimen<br />

169<br />

3. Results<br />

Figure 2. Comparison of residual stress values from the<br />

FE analysis and ND for 53 kN pre-compressed C(T)s<br />

4. Conclusion<br />

The measured data from ND for two C(T) specimens<br />

are in very good agreement and confirms the tests<br />

repeatability. Residual stress profiles measured using<br />

ND, provide a good agreement with the plane stress<br />

results from the FE analysis. The surface and smearing<br />

effects due to the gauge volume size may cause the<br />

disparities near the notch tip that is seen in both free<br />

edges of the specimens. It is seen that the kinematic<br />

hardening material model may improve the agreements<br />

close to the notch root by predicting a lower stress<br />

level. Though not shown here, creep relaxation<br />

behaviour was also studied numerically and compared<br />

with the earlier studies.<br />

5. References<br />

[1] R6, Revision 4, 2009, “Assessment of the Integrity of<br />

Structures Containing Defects'”, British Energy Generation<br />

Ltd., Gloucester, UK.<br />

[2] R5, Revision 3, 2003, “An Assessment Procedure for the<br />

High Temperature Response of Structures”, British Energy<br />

Generation Ltd., Gloucester, UK.<br />

[3] Turski, M., Bouchard, P.J., Steuwer, A., Withers P.J.,<br />

2008, “Residual Stress Driven Creep Cracking in AISI Type<br />

316 Stainless Steel”, J. Acta Materialia, 56 (14), 3598-3612.