NUI Galway – UL Alliance First Annual ENGINEERING AND - ARAN ...

NUI Galway – UL Alliance First Annual ENGINEERING AND - ARAN ...

NUI Galway – UL Alliance First Annual ENGINEERING AND - ARAN ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

The Elasto-Plastic Properties of Trabecular Bone and Polyurethane Foam:<br />

An Experimental and Computational Characterisation<br />

Kelly, N. 1,2 , McGarry, J.P. 1,2<br />

1 Department of Mechanical and Biomedical Engineering, National University of Ireland, <strong>Galway</strong><br />

2 National Centre for Biomedical Engineering Science, National University of Ireland, <strong>Galway</strong><br />

n.kelly3@nuigalway.ie<br />

Abstract<br />

During compressive loading trabecular bone can<br />

undergo extensive inelastic deformation reaching<br />

strains up to 60 % prior to ultimate failure [1] . Previous<br />

bone plasticity studies have considered a number of<br />

pressure dependent constitutive formulations including<br />

the Drucker-Prager (DP) and Mohr-Coulomb (MC)<br />

models [1-3] . The crushable foam (CF) plasticity model<br />

has been used to model polymeric foams but has not<br />

been investigated for trabecular bone.<br />

1. Introduction<br />

The current study entails a detailed experimental and<br />

numerical investigation of the inelastic behaviour of<br />

bovine trabecular bone (BTB) and a commercially<br />

available trabecular bone analogue material (PU foam,<br />

sawbones). Material behaviour under conditions of<br />

unconfined and confined compression is determined and<br />

a suitable inelastic constitutive formulation is identified.<br />

Specifically the following constitutive formulations are<br />

investigated: DP; MC; isotropic crushable foam (CFiso);<br />

volumetric crushable foam (CFvol). Following this, we<br />

investigate the surgical implantation of a tibial<br />

component (Genesis II, Smith&Nephew) into a sawbone<br />

tibia (composed of PU foam to replicate trabecular<br />

bone) to identify if material yield occurs.<br />

2. Materials and Methods<br />

Experimental: 15 mm cubic specimens of PU foam<br />

(ρ = 0.16 g/cm 3 ) and proximal tibial BTB were tested<br />

destructively in unconfined and confined (custom rig)<br />

uniaxial compression at a rate of 5 mm/min (Instron<br />

4467, Instron Corp., USA).<br />

Computational: 3D FE confined and unconfined<br />

uniaxial compression tests of PU and BTB were<br />

simulated (Abaqus v6.8). A 3D FE model was created<br />

to simulate surgical tibial component implantation into a<br />

sawbone tibia (#3402) (Fig.1B). Frictionless contact<br />

was assumed between the components.<br />

3. Results & Discussion<br />

Experimental and computational results for PU foam<br />

and BTB are shown in Fig.1A. Unconfined<br />

experimental results for PU (E = 35 MPa, σy = 1.5 MPa)<br />

and BTB (E = 364 MPa, σy = 10 MPa) are within the<br />

reported range for human trabecular bone [6] . Simulation<br />

of tibial component implantation results in a maximum<br />

computed stress of ~14 MPa (Fig.1B-C).<br />

60<br />

(A)<br />

Nominal Stress (MPa)<br />

Nominal Stress (MPa)<br />

Nominal Stress (MPa)<br />

Nominal Stress (MPa)<br />

3<br />

2<br />

1<br />

0<br />

5 53<br />

0 4 4<br />

2<br />

3 3<br />

0.1 0.2 0.2 0.3 0.3 0.4 0.4<br />

Nominal<br />

PU Nominal Strain<br />

Foam Confined Strain<br />

0.5 0.5 0.6 0.6<br />

Nominal Stress (MPa)<br />

2 2<br />

1<br />

1 1<br />

PU Foam Unconfined<br />

0 0<br />

0 0<br />

0.1 0.1 0.2<br />

0.2 0.2 0.3<br />

0.3 0.3 0.4<br />

0.4 0.4 0.5<br />

0.5 0.5<br />

Nominal<br />

Nominal Strain<br />

Strain<br />

Cfiso<br />

Cfiso<br />

Cfvol<br />

Cfvol<br />

MC<br />

MC<br />

DP<br />

DP<br />

Experimental<br />

Experimental<br />

0.6<br />

0.6 0.6<br />

Nominal Stress (MPa)<br />

Nominal Stress (MPa)<br />

Nominal Stress (MPa)<br />

Nominal Stress (MPa)<br />

Nominal Stress (MPa)<br />

BTB Unconfined<br />

0<br />

0<br />

5 0<br />

100<br />

100<br />

4<br />

80<br />

80<br />

3<br />

60<br />

60<br />

40 2<br />

40<br />

20<br />

20 1<br />

0.1<br />

0.1<br />

0.2 0.3<br />

0.2 0.3<br />

Nominal<br />

Nominal<br />

BTB Confined Strain<br />

Strain<br />

0.4<br />

0.4<br />

0<br />

0<br />

0 0.1 0.2 0.3<br />

0 0.1 0.1 0.2 0.3 0.2 0.4 0.3 0.5<br />

Nominal Strain<br />

Cfiso Cfvol Nominal<br />

Nominal<br />

MC DP Strain<br />

Strain<br />

Experimental<br />

CFiso CFvol MC DP Experimental<br />

CFiso CFvol MC DP Experimental<br />

Mises/σy 0.6<br />

(B) (C)<br />

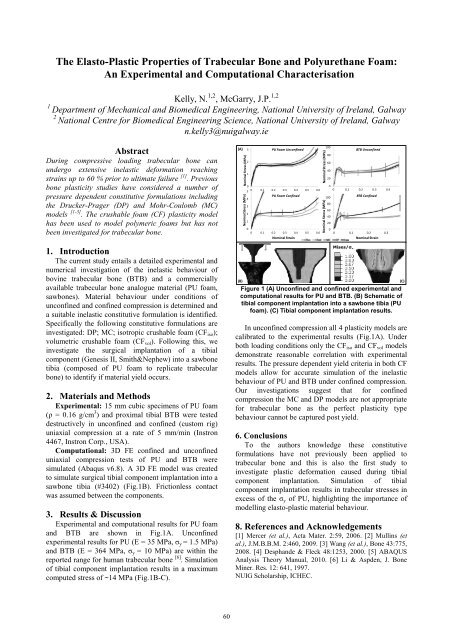

Figure 1 (A) Unconfined and confined experimental and<br />

computational results for PU and BTB. (B) Schematic of<br />

tibial component implantation into a sawbone tibia (PU<br />

foam). (C) Tibial component implantation results.<br />

In unconfined compression all 4 plasticity models are<br />

calibrated to the experimental results (Fig.1A). Under<br />

both loading conditions only the CFiso and CFvol models<br />

demonstrate reasonable correlation with experimental<br />

results. The pressure dependent yield criteria in both CF<br />

models allow for accurate simulation of the inelastic<br />

behaviour of PU and BTB under confined compression.<br />

Our investigations suggest that for confined<br />

compression the MC and DP models are not appropriate<br />

for trabecular bone as the perfect plasticity type<br />

behaviour cannot be captured post yield.<br />

6. Conclusions<br />

To the authors knowledge these constitutive<br />

formulations have not previously been applied to<br />

trabecular bone and this is also the first study to<br />

investigate plastic deformation caused during tibial<br />

component implantation. Simulation of tibial<br />

component implantation results in trabecular stresses in<br />

excess of the σy of PU, highlighting the importance of<br />

modelling elasto-plastic material behaviour.<br />

8. References and Acknowledgements<br />

[1] Mercer (et al.), Acta Mater. 2:59, 2006. [2] Mullins (et<br />

al.), J.M.B.B.M. 2:460, 2009. [3] Wang (et al.), Bone 43:775,<br />

2008. [4] Desphande & Fleck 48:1253, 2000. [5] ABAQUS<br />

Analysis Theory Manual, 2010. [6] Li & Aspden, J. Bone<br />

Miner. Res. 12: 641, 1997.<br />

<strong>NUI</strong>G Scholarship, ICHEC.<br />

100<br />

100<br />

80<br />

80<br />

60<br />

60<br />

40<br />

40<br />

20<br />

20