NUI Galway – UL Alliance First Annual ENGINEERING AND - ARAN ...

NUI Galway – UL Alliance First Annual ENGINEERING AND - ARAN ...

NUI Galway – UL Alliance First Annual ENGINEERING AND - ARAN ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Mechanical Properties of Hydroxyapatite using a Dispersal Phase of Nano-<br />

Zirconia and Sintering using Conventional and Microwave Methods<br />

Declan J Curran<br />

Thomas J Fleming, Mark R Towler, Stuart Hampshire<br />

declan.curran@ul.ie<br />

Abstract<br />

Laboratory synthesized hydroxyapatite (HA) and<br />

commercial nano-sized zirconia (ZrO2) were<br />

comparatively sintered using conventional and<br />

microwave methods at temperatures of 700, 1000, and<br />

1200 o C. The microwave sintered (MS) samples show<br />

less decomposition than their conventionally sintered<br />

(CS) counterparts. Stabilisation of the ZrO2 phase<br />

occurs in small amounts in both the CS and MS samples<br />

at 1200 o C. Increasing sintering temperature increases<br />

density, with no discernable difference between regimes<br />

at 1200 o C. The change in relative density is determined<br />

as the main controlling factor over the mechanical<br />

properties. The nano-sized ZrO2 has no strengthening<br />

effects. Instead it works to hinder densification.<br />

1. Introduction<br />

Due to its resemblance to the mineral phase of bone,<br />

hydroxyapatite (HA) [Ca10(PO4)3(OH)2] is used in an<br />

increasing number of medical applications. HA has been<br />

shown to be both bio-compatible and osteo-conductive<br />

[1], allowing it to promote new bone growth in-vivo<br />

without eliciting an immune response. The inherent low<br />

mechanical strength and brittleness of HA have<br />

excluded its employment as a load bearing implant.<br />

Sintering at high temperatures can result in the<br />

formation of calcium phosphate based decomposition<br />

products that, in certain instances, have been reported to<br />

adversely affect biological response [2]. Zirconia (ZrO2)<br />

has a high fracture toughness and is relatively bio-inert,<br />

and as such provides an ideal toughening material for<br />

implant applications. However, high sintering<br />

temperatures are required to fully densify ZrO2. In this<br />

work HA-ZrO2 composites have been fabricated from<br />

nano-sized powders to reduce the activation energies<br />

necessary to cause densification. In addition,<br />

microwave sintering is used to reduce sintering<br />

temperatures.<br />

2. Materials & Methods<br />

Laboratory synthesized HA, which was evaluated for<br />

quality, was ball-milled with 0, 1, 2, 3, 4 and 5wt%<br />

commercial nano-sized ZrO2 powder to ensure<br />

homogeneity and to break up any soft agglomerates.<br />

Cylindrical green bodies ~3mm thick & ~19mm Ø were<br />

uniaxially pressed (5000 Kg , 20 seconds). Comparative<br />

microwave and conventional sintering regimes were<br />

done on the samples. The physical and mechanical<br />

properties were then determined.<br />

176<br />

3. Results & Discussion<br />

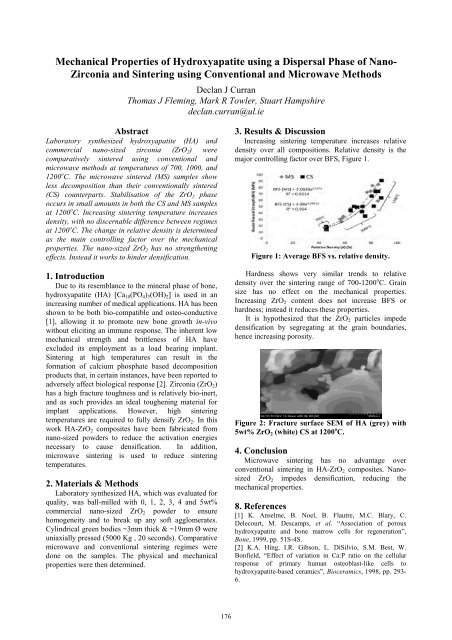

Increasing sintering temperature increases relative<br />

density over all compositions. Relative density is the<br />

major controlling factor over BFS, Figure 1.<br />

Figure 1: Average BFS vs. relative density.<br />

Hardness shows very similar trends to relative<br />

density over the sintering range of 700-1200 o C. Grain<br />

size has no effect on the mechanical properties.<br />

Increasing ZrO2 content does not increase BFS or<br />

hardness; instead it reduces these properties.<br />

It is hypothesized that the ZrO2 particles impede<br />

densification by segregating at the grain boundaries,<br />

hence increasing porosity.<br />

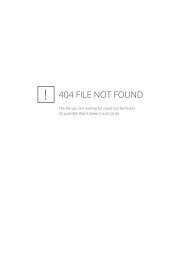

Figure 2: Fracture surface SEM of HA (grey) with<br />

5wt% ZrO2 (white) CS at 1200 o C.<br />

4. Conclusion<br />

Microwave sintering has no advantage over<br />

conventional sintering in HA-ZrO2 composites. Nanosized<br />

ZrO2 impedes densification, reducing the<br />

mechanical properties.<br />

8. References<br />

[1] K. Anselme, B. Noel, B. Flautre, M.C. Blary, C.<br />

Delecourt, M. Descamps, et al. “Association of porous<br />

hydroxyapatite and bone marrow cells for regeneration”,<br />

Bone, 1999, pp. 51S-4S.<br />

[2] K.A. Hing, I.R. Gibson, L. DiSilvio, S.M. Best, W.<br />

Bonfield, “Effect of variation in Ca:P ratio on the cellular<br />

response of primary human osteoblast-like cells to<br />

hydroxyapatite-based ceramics”, Bioceramics, 1998, pp. 293-<br />

6.