NUI Galway – UL Alliance First Annual ENGINEERING AND - ARAN ...

NUI Galway – UL Alliance First Annual ENGINEERING AND - ARAN ...

NUI Galway – UL Alliance First Annual ENGINEERING AND - ARAN ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

The effect of citrate ester plasticizers on the thermal and dynamic mechanical<br />

properties of Poly (DL lactide) for use as medical implants<br />

Imelda Harte<br />

Department of Civil Engineering and Material Science, University of Limerick<br />

Imelda.harte@ul.ie<br />

Abstract<br />

Poly (D,L lactide) (PDLLA) was blended with three<br />

different citrate ester plasticizers and the resultant<br />

blends were analyzed using differential scanning<br />

calorimetry (DSC) and dynamic mechanical thermal<br />

analysis (DMTA). Each plasticizer was miscible with<br />

the polymer for all compositions and with increasing<br />

plasticizer content a decrease in Tg was obtained.<br />

1. Introduction<br />

Developing degradable polymers as medical<br />

implants is of great research interest. Polylactide (PLA)<br />

is a thermoplastic polymer with hydrolytically labile<br />

aliphatic ester linkages in its backbone. It is considered<br />

safe, non-toxic and biocompatible for use as an<br />

implantable biomaterial. However, PLA devices tend to<br />

be susceptible to fracture when subjected to tension or<br />

load bearing stresses during use. [1]<br />

In order to modify its properties, PDLLA has been<br />

blended with citrate esters plasticizers, which are nontoxic<br />

and approved for use in medical plastics.<br />

2. Methods<br />

Poly (D,L lactide) (PDLLA) was blended with three<br />

different citrate esters; triethyl citrate (TEC), tributyl<br />

citrate (TBC) and acetyl tributyl citrate (ATBC) and the<br />

resultant thermal and mechanical properties were<br />

analyzed. DSC was preformed using a Perkin-Elmer<br />

Pyris 1 DSC, while DMTA scans were carried out using<br />

a Rheometric scientific mark 3.<br />

3. Results<br />

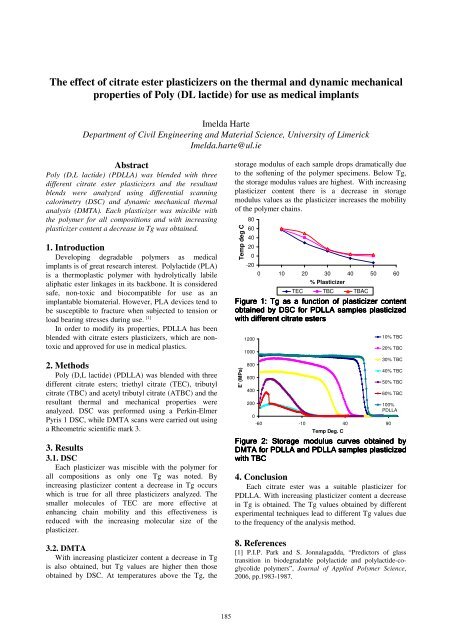

3.1. DSC<br />

Each plasticizer was miscible with the polymer for<br />

all compositions as only one Tg was noted. By<br />

increasing plasticizer content a decrease in Tg occurs<br />

which is true for all three plasticizers analyzed. The<br />

smaller molecules of TEC are more effective at<br />

enhancing chain mobility and this effectiveness is<br />

reduced with the increasing molecular size of the<br />

plasticizer.<br />

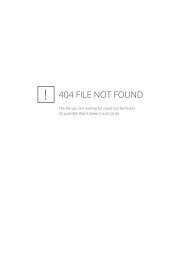

3.2. DMTA<br />

With increasing plasticizer content a decrease in Tg<br />

is also obtained, but Tg values are higher then those<br />

obtained by DSC. At temperatures above the Tg, the<br />

185<br />

storage modulus of each sample drops dramatically due<br />

to the softening of the polymer specimens. Below Tg,<br />

the storage modulus values are highest. With increasing<br />

plasticizer content there is a decrease in storage<br />

modulus values as the plasticizer increases the mobility<br />

of the polymer chains.<br />

Temp deg C<br />

80<br />

60<br />

40<br />

20<br />

0<br />

-20<br />

0 10 20 30 40 50 60<br />

% Plasticizer<br />

TEC TBC TBAC<br />

Figure Figure 1: Tg Tg Tg as as a a function function of of plasticizer plasticizer content<br />

content<br />

obtained obtained by by by DSC DSC DSC for for PDLLA PDLLA PDLLA samples samples plasticized plasticized<br />

plasticized<br />

with with different different citrate citrate esters<br />

esters<br />

E' (MPa)<br />

1200<br />

1000<br />

800<br />

600<br />

400<br />

200<br />

0<br />

-60 -10 40 90<br />

Temp Deg. C<br />

10% TBC<br />

20% TBC<br />

30% TBC<br />

40% TBC<br />

50% TBC<br />

60% TBC<br />

100%<br />

PDLLA<br />

Figure Figure 2: Sto Storage Sto<br />

rage rage modulus modulus curves curves obtained obtained by<br />

by<br />

DMTA DMTA for for for PDLLA PDLLA and and PDLLA PDLLA PDLLA samples samples samples plasticized<br />

plasticized<br />

with with TBC<br />

4. Conclusion<br />

Each citrate ester was a suitable plasticizer for<br />

PDLLA. With increasing plasticizer content a decrease<br />

in Tg is obtained. The Tg values obtained by different<br />

experimental techniques lead to different Tg values due<br />

to the frequency of the analysis method.<br />

8. References<br />

[1] P.I.P. Park and S. Jonnalagadda, “Predictors of glass<br />

transition in biodegradable polylactide and polylactide-coglycolide<br />

polymers”, Journal of Applied Polymer Science,<br />

2006, pp.1983-1987.