NUI Galway – UL Alliance First Annual ENGINEERING AND - ARAN ...

NUI Galway – UL Alliance First Annual ENGINEERING AND - ARAN ...

NUI Galway – UL Alliance First Annual ENGINEERING AND - ARAN ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

High Resolution Microscopical Analysis of Metallurgical Grade Nanoporous<br />

Silicon Particles<br />

E.G. Chadwick 1,2* , D.A. Tanner 1,2 , S. Beloshapkin 1 , H. Zhang 3 , G. Behan 3<br />

1 Materials & Surface Science Institute, University of Limerick, Ireland<br />

2 Department of Design and Manufacturing Technology, University of Limerick, Ireland<br />

3 School of Physics and CRANN, Trinity College, Dublin, Ireland<br />

Abstract<br />

Porous silicon finds numerous applications in the areas<br />

of bio-technology, drug delivery & energetic materials.<br />

This work studies the structural morphology of<br />

chemically etched porous silicon particles using high<br />

resolution electron microscopy techniques combined<br />

with porisometry type measurements. The surface pore<br />

structure is examined in detail using Scanning Electron<br />

Microscopy and Transmission Electron Microscopy<br />

while the internal pore structure is explored using<br />

Focused Ion Beam milling and Ultramicrotomed crosssections.<br />

1. Introduction<br />

Porous Silicon (PS) is a sponge like structure that is<br />

formed when bulk Silicon (Si) is etched either<br />

chemically or electrochemically in hydrofluoric acid<br />

based solutions [1-4]. Since Canham made the<br />

discovery of its room temperature photoluminescence<br />

[1-3], subsequent research followed focusing on<br />

developing possible PS applications in such areas as<br />

microelectronics, chemical and biological sensors [4].<br />

Mesoporous and nanoporous Si is also currently being<br />

investigated for drug delivery, bioactive and energetic<br />

materials applications [5, 6, 7]. The possible<br />

applications of PS would now seem abundant and<br />

therefore microscopical analysis of the material is<br />

critical to aiding in the development of new PS<br />

applications. Vesta Sciences have recently developed<br />

PS nanosponge particles from metallurgical grade Si<br />

through their own patented chemical etching process<br />

(Irish patent no. IE20060360). The work presented here,<br />

studies the structural morphology of these PS<br />

nanosponge particles using high resolution microscopy<br />

techniques to fully characterise the material. The related<br />

surface pore structure is examined in detail and the<br />

internal pore structure is explored using a combination<br />

of sample-prep methods and FIB milling, SEM, TEM &<br />

Helium Ion Microscopy.<br />

2. Results/Discussion<br />

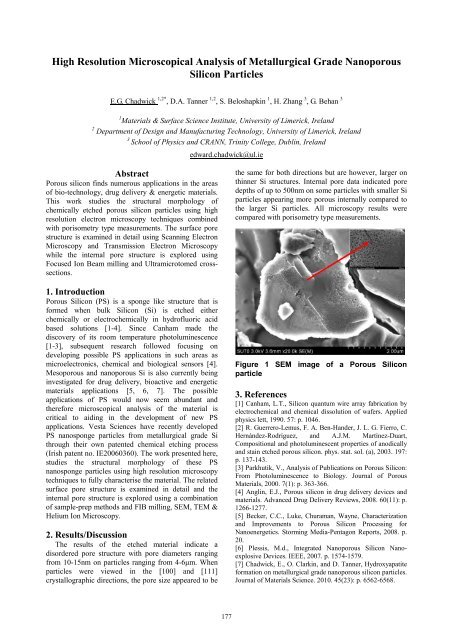

The results of the etched material indicate a<br />

disordered pore structure with pore diameters ranging<br />

from 10-15nm on particles ranging from 4-6µm. When<br />

particles were viewed in the [100] and [111]<br />

crystallographic directions, the pore size appeared to be<br />

edward.chadwick@ul.ie<br />

177<br />

the same for both directions but are however, larger on<br />

thinner Si structures. Internal pore data indicated pore<br />

depths of up to 500nm on some particles with smaller Si<br />

particles appearing more porous internally compared to<br />

the larger Si particles. All microscopy results were<br />

compared with porisometry type measurements.<br />

Figure 1 SEM image of a Porous Silicon<br />

particle<br />

3. References<br />

[1] Canham, L.T., Silicon quantum wire array fabrication by<br />

electrochemical and chemical dissolution of wafers. Applied<br />

physics lett, 1990. 57: p. 1046.<br />

[2] R. Guerrero-Lemus, F. A. Ben-Hander, J. L. G. Fierro, C.<br />

Hernández-Rodríguez, and A.J.M. Martínez-Duart,<br />

Compositional and photoluminescent properties of anodically<br />

and stain etched porous silicon. phys. stat. sol. (a), 2003. 197:<br />

p. 137-143.<br />

[3] Parkhutik, V., Analysis of Publications on Porous Silicon:<br />

From Photoluminescence to Biology. Journal of Porous<br />

Materials, 2000. 7(1): p. 363-366.<br />

[4] Anglin, E.J., Porous silicon in drug delivery devices and<br />

materials. Advanced Drug Delivery Reviews, 2008. 60(11): p.<br />

1266-1277.<br />

[5] Becker, C.C., Luke, Churaman, Wayne, Characterization<br />

and Improvements to Porous Silicon Processing for<br />

Nanoenergetics. Storming Media-Pentagon Reports, 2008. p.<br />

20.<br />

[6] Plessis, M.d., Integrated Nanoporous Silicon Nanoexplosive<br />

Devices. IEEE, 2007. p. 1574-1579.<br />

[7] Chadwick, E., O. Clarkin, and D. Tanner, Hydroxyapatite<br />

formation on metallurgical grade nanoporous silicon particles.<br />

Journal of Materials Science. 2010. 45(23): p. 6562-6568.