NUI Galway – UL Alliance First Annual ENGINEERING AND - ARAN ...

NUI Galway – UL Alliance First Annual ENGINEERING AND - ARAN ...

NUI Galway – UL Alliance First Annual ENGINEERING AND - ARAN ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

FATIGUE OF NITINOL: EXPERIMENTAL <strong>AND</strong> COMPUTATIONAL<br />

ANALYSIS ON THE EFFECT OF STENT CRIMPING<br />

Abstract<br />

One material that has found particular favour within<br />

the biomedical industry is the near equi-atomic NiTi<br />

alloy, Nitinol. This can be directly attributed to its<br />

characteristic shape memory and superelastic<br />

behaviour. Nitinol self-expanding endovascular stents<br />

are effective in the treatment of peripheral artery<br />

disease, including the superficial femoral, carotid, and<br />

renal arteries. However, fracture rates of 65.4% in<br />

stents used in the superior femoral artery have been<br />

reported [1]. Such failures have been attributed to<br />

cumulative fatigue damage. Accurate characterisation<br />

of the fatigue behaviour of such stents is therefore<br />

essential for their prolonged safe use in human arteries.<br />

1. Introduction<br />

During manufacture, stents are crimped to fit within<br />

a catheter to allow in vivo deployment. This process<br />

exerts a significant crimping strain on the stent<br />

geometry. Consequently, the focus of this study is to<br />

investigate the effect of crimping strain on the fatigue<br />

life of Nitinol stents under strain control conditions.<br />

2. Materials and Methods<br />

Nitinol 'v-strut' stent-like specimens were supplied by<br />

Veryan Medical. Excess material at both ends, along<br />

with support struts, were included in the design to<br />

provide precise alignment, structural stability and secure<br />

gripping during testing. To accurately characterise the<br />

material properties, uniaxial tensile tests were<br />

performed on the support strut. The EnduraTEC<br />

ELF/3200 was employed for this study. The<br />

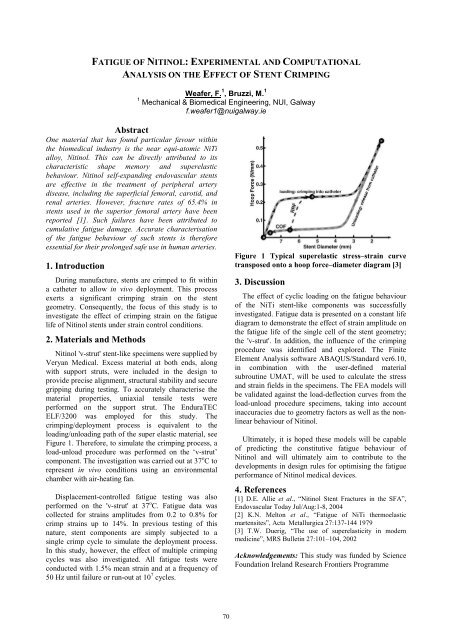

crimping/deployment process is equivalent to the<br />

loading/unloading path of the super elastic material, see<br />

Figure 1. Therefore, to simulate the crimping process, a<br />

load-unload procedure was performed on the ‘v-strut’<br />

component. The investigation was carried out at 37 o C to<br />

represent in vivo conditions using an environmental<br />

chamber with air-heating fan.<br />

Displacement-controlled fatigue testing was also<br />

performed on the 'v-strut' at 37 o C. Fatigue data was<br />

collected for strains amplitudes from 0.2 to 0.8% for<br />

crimp strains up to 14%. In previous testing of this<br />

nature, stent components are simply subjected to a<br />

single crimp cycle to simulate the deployment process.<br />

In this study, however, the effect of multiple crimping<br />

cycles was also investigated. All fatigue tests were<br />

conducted with 1.5% mean strain and at a frequency of<br />

50 Hz until failure or run-out at 10 7 cycles.<br />

Weafer, F. 1 , Bruzzi, M. 1<br />

1 Mechanical & Biomedical Engineering, <strong>NUI</strong>, <strong>Galway</strong><br />

f.weafer1@nuigalway.ie<br />

70<br />

Figure 1 Typical superelastic stress<strong>–</strong>strain curve<br />

transposed onto a hoop force<strong>–</strong>diameter diagram [3]<br />

3. Discussion<br />

The effect of cyclic loading on the fatigue behaviour<br />

of the NiTi stent-like components was successfully<br />

investigated. Fatigue data is presented on a constant life<br />

diagram to demonstrate the effect of strain amplitude on<br />

the fatigue life of the single cell of the stent geometry;<br />

the 'v-strut'. In addition, the influence of the crimping<br />

procedure was identified and explored. The Finite<br />

Element Analysis software ABAQUS/Standard ver6.10,<br />

in combination with the user-defined material<br />

subroutine UMAT, will be used to calculate the stress<br />

and strain fields in the specimens. The FEA models will<br />

be validated against the load-deflection curves from the<br />

load-unload procedure specimens, taking into account<br />

inaccuracies due to geometry factors as well as the nonlinear<br />

behaviour of Nitinol.<br />

Ultimately, it is hoped these models will be capable<br />

of predicting the constitutive fatigue behaviour of<br />

Nitinol and will ultimately aim to contribute to the<br />

developments in design rules for optimising the fatigue<br />

performance of Nitinol medical devices.<br />

4. References<br />

[1] D.E. Allie et al., “Nitinol Stent Fractures in the SFA”,<br />

Endovascular Today Jul/Aug:1-8, 2004<br />

[2] K.N. Melton et al., “Fatigue of NiTi thermoelastic<br />

martensites”, Acta Metallurgica 27:137-144 1979<br />

[3] T.W. Duerig, “The use of superelasticity in modern<br />

medicine”, MRS Bulletin 27:101<strong>–</strong>104, 2002<br />

Acknowledgements: This study was funded by Science<br />

Foundation Ireland Research Frontiers Programme