NUI Galway – UL Alliance First Annual ENGINEERING AND - ARAN ...

NUI Galway – UL Alliance First Annual ENGINEERING AND - ARAN ...

NUI Galway – UL Alliance First Annual ENGINEERING AND - ARAN ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Influence of Fluorine and Nitrogen on the IR Transmission of Glasses<br />

C. M. Crowley a and S. Hampshire a ,<br />

a Department of Materials Science and Technology, University of Limerick, Ireland<br />

b Department of Chemical and Environmental Sciences, University of Limerick, Ireland<br />

Clare.Crowley@ul.ie<br />

Abstract<br />

The influence of glass chemistry and firing conditions<br />

on the thermomechanical properties and IR<br />

transmission of aluminosilicate, sialon, fluorinated<br />

aluminosilicate and fluorinated sialon glasses has been<br />

examined. Improvements in the thermomechanical<br />

properties were achieved with increasing nitrogen<br />

content while a concomitant improvement in IR<br />

transmission was achieved under specific firing<br />

conditions.<br />

Introduction<br />

Glass is commonly used as a medium to transmit<br />

infrared (IR) radiation in applications. Glasses,<br />

however, normally contain water impurities in their<br />

atomic structure which are efficient absorbers of IR<br />

radiation leading to energy loss and heat generation in<br />

the glass. Commercial producers of IR glasses<br />

overcome this by employing expensive processes and<br />

ultra pure materials. The incorporation of nitrogen into<br />

rare-earth aluminosilicate glasses has previously been<br />

shown to enhance infrared transmission due to the<br />

reduction in the formation of silanols in the glass<br />

network [1]. However, the production cost of rare-earth<br />

sialon glasses, fired under reducing conditions, is not<br />

commercially viable. In this study the feasibility of<br />

using nitrogen-based glasses to reduce the occurrence<br />

of ‘water’ impurities in alkali-earth sialon glasses has<br />

been examined.<br />

Materials and Methods<br />

Glass compositions<br />

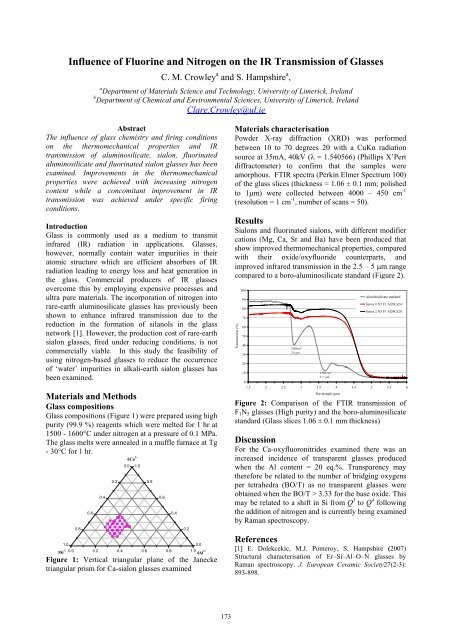

Glass compositions (Figure 1) were prepared using high<br />

purity (99.9 %) reagents which were melted for 1 hr at<br />

1500 - 1600°C under nitrogen at a pressure of 0.1 MPa.<br />

The glass melts were annealed in a muffle furnace at Tg<br />

- 30°C for 1 hr.<br />

0.8<br />

0.6<br />

0.4<br />

0.2<br />

6Ca<br />

0.0 1.0<br />

2+<br />

1.0 0.0<br />

0.0 0.2 0.4 0.6 0.8 1.0<br />

4Al 3+<br />

3Si 4+<br />

Figure 1: Vertical triangular plane of the Janecke<br />

triangular prism for Ca-sialon glasses examined<br />

0.8<br />

0.6<br />

0.4<br />

0.2<br />

173<br />

Materials characterisation<br />

Powder X-ray diffraction (XRD) was performed<br />

between 10 to 70 degrees 2 with a CuKα radiation<br />

source at 35mA, 40kV ( = 1.540566) (Phillips X’Pert<br />

diffractometer) to confirm that the samples were<br />

amorphous. FTIR spectra (Perkin Elmer Spectrum 100)<br />

of the glass slices (thickness = 1.06 ± 0.1 mm; polished<br />

to 1m) were collected between 4000 <strong>–</strong> 450 cm -1<br />

(resolution = 1 cm -1 , number of scans = 50).<br />

Results<br />

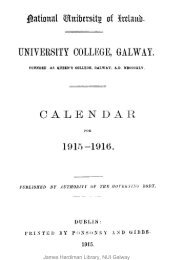

Sialons and fluorinated sialons, with different modifier<br />

cations (Mg, Ca, Sr and Ba) have been produced that<br />

show improved thermomechanical properties, compared<br />

with their oxide/oxyfluoride counterparts, and<br />

improved infrared transmission in the 2.5 <strong>–</strong> 5 m range<br />

compared to a boro-aluminosilicate standard (Figure 2).<br />

Transmission (%)<br />

100<br />

90<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

3588cm -1<br />

2.8m<br />

10<br />

0<br />

2703 cm<br />

1.5 2 2.5 3 3.5 4 4.5 5 5.5 6<br />

-1<br />

3.7 m<br />

Wavelength (m)<br />

Aluminosilicate standard<br />

Series 6 N5 F1 Al20Ca24<br />

Series 2 N5 F1 Al24Ca20<br />

Figure 2: Comparison of the FTIR transmission of<br />

F1N5 glasses (High purity) and the boro-aluminosilicate<br />

standard (Glass slices 1.06 ± 0.1 mm thickness)<br />

Discussion<br />

For the Ca-oxyfluoronitrides examined there was an<br />

increased incidence of transparent glasses produced<br />

when the Al content = 20 eq.%. Transparency may<br />

therefore be related to the number of bridging oxygens<br />

per tetrahedra (BO/T) as no transparent glasses were<br />

obtained when the BO/T > 3.33 for the base oxide. This<br />

may be related to a shift in Si from Q 3 to Q 4 following<br />

the addition of nitrogen and is currently being examined<br />

by Raman spectroscopy.<br />

References<br />

[1] E. Dolekcekic, M.J. Pomeroy, S. Hampshire (2007)<br />

Structural characterisation of Er<strong>–</strong>Si<strong>–</strong>Al<strong>–</strong>O<strong>–</strong>N glasses by<br />

Raman spectroscopy. J. European Ceramic Society27(2-3):<br />

893-898.