Html - PUMA CATch up

Html - PUMA CATch up

Html - PUMA CATch up

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

p : 55 | c : 3 <strong>PUMA</strong>.SAfe<br />

chemicals managemenT<br />

<strong>PUMA</strong>’s efforts to protect consumers<br />

and the environment against<br />

hazardous chemicals dates back<br />

to 1999 when we released our<br />

first Handbook of Environmental<br />

Standards. The Handbook has since<br />

provided guidance to our s<strong>up</strong>pliers, testing<br />

institutes, chemical companies and other<br />

stakeholders. It is <strong>up</strong>dated periodically to<br />

reflect the latest legal requirements and<br />

tightest industry standards.<br />

In 2012, <strong>PUMA</strong> split its established Handbook<br />

into two volumes: “Volume 1 - Environmental<br />

Management” covering all environmental<br />

related topics and “Volume 2 - Chemicals<br />

Management” covering our restricted<br />

substances list (RSL) and the Manufacturing<br />

Restricted Substances List (MRSL). The<br />

decision to have a separate handbook<br />

dedicated to the responsible<br />

handling of chemical<br />

volume 1.<br />

environment<br />

management<br />

puma.safe<br />

handbook of<br />

environmental<br />

standards<br />

› click here<br />

volume 2.<br />

chemical<br />

management<br />

<strong>PUMA</strong> BUSineSS And SUStAinABility RePoRt 2012<br />

rsl-producTs<br />

(shoes,<br />

accessories,<br />

garments)<br />

mrsl-facTory<br />

manufacturing<br />

processes<br />

(emissions to environment:<br />

air, water,<br />

ground,etc,)<br />

substances originated from <strong>PUMA</strong>’s commitment<br />

to eliminate hazardous chemicals<br />

from its manufacturing process by 2020<br />

(Zero Discharge of Hazardous Chemicals by<br />

2020). The <strong>up</strong>dated version includes a section<br />

on restricted substances in products<br />

and production, whereas test methods and<br />

limit values are included in <strong>PUMA</strong>’s RSL and<br />

MRSL. The Handbook was communicated<br />

and delivered to s<strong>up</strong>pliers and relevant<br />

stakeholders in October 2012.<br />

› please click here<br />

puma’s resTricTed suBsTances lisT<br />

and manufacTuring resTricTed<br />

suBsTances lisT<br />

To ensure consumer safety, <strong>PUMA</strong> <strong>up</strong>dates<br />

its Restricted Substances List (RSL)<br />

›› please click here in compliance with new<br />

product safety regulations including<br />

US CPSIA, EU REACH, China GB<br />

standards and all relevant coun-<br />

tries where <strong>PUMA</strong> products are<br />

distributed and sold. At the beginning<br />

of 2012 <strong>PUMA</strong> communicated<br />

to its s<strong>up</strong>pliers that no<br />

alkylphenolethoxylates (APEOs)<br />

must be used in manufacturing,<br />

lowering the limit value to 100 mg/kg.<br />

No nonylphenol, a toxic substance that<br />

can be formed from APEOs, must be<br />

detectable in <strong>PUMA</strong>s products.<br />

roadmap To Zero discharge of<br />

haZardous chemicals By 2020<br />

Our commitment to Zero Discharge<br />

of Hazardous Chemicals (ZDHC) by<br />

2020 resulted not only in a new handbook<br />

but also in a ZDHC working gro<strong>up</strong>. This industry<br />

collaboration was set <strong>up</strong> in 2011,<br />

and nine signatory member companies are<br />

working together towards an ambitious<br />

goal, guided by a joint › roadmap, a document<br />

that frames the projects and work<br />

done within the gro<strong>up</strong>. The ZDHC working<br />

gro<strong>up</strong> looks back at an intensive first year.<br />

Project <strong>up</strong>dates and further information are<br />

available on › www.roadmaptozero.com.<br />

In addition to participation in this working<br />

gro<strong>up</strong>, <strong>PUMA</strong> has realized its own action<br />

plan › please click here to materialize what<br />

<strong>PUMA</strong> has committed to. The phase-out of<br />

hazardous chemicals in the s<strong>up</strong>ply chain<br />

will be integrated into <strong>PUMA</strong>’s new Sustainability<br />

Scorecard 2015. Furthermore, <strong>PUMA</strong><br />

f.9 t.1<br />

80,00<br />

70,00<br />

60,00<br />

50,00<br />

40,00<br />

30,00<br />

20,00<br />

10,00<br />

0,00<br />

25<br />

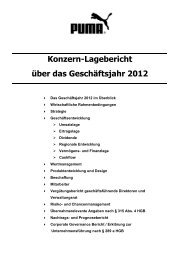

puma voc daTa 2003 – 2012<br />

66.72<br />

56.22<br />

46.84<br />

has encouraged strategic s<strong>up</strong>pliers to disclose<br />

their chemicals management systems<br />

in their own sustainability reports starting<br />

2012. First reports will be published in the<br />

year ahead, and we highly appreciate this<br />

small step towards enhanced transparency.<br />

volaTile organic compounds in shoes<br />

In a quest to find more ways of using water-based<br />

chemicals, <strong>PUMA</strong> continues its<br />

monthly monitoring of the levels of volatile<br />

organic compounds (VOC) per pair of shoes.<br />

We want to make the use of chemicals more<br />

efficient and therefore reduce our use of<br />

VOC-based chemicals in our shoe production<br />

to achieve the target of 25g per pair. The<br />

chart below shows the progress of our VOC<br />

use:<br />

43.00 42.19 39.82 41.19<br />

2003 2004 2005 2006 2007 2008 2009 2010<br />

40.22<br />

Measured VOC<br />

Target<br />

37.02<br />

2011<br />

33.07<br />

2012<br />

Figure 9: Avarage VOC consumption per pair of <strong>PUMA</strong> shoes<br />

25