Html - PUMA CATch up

Html - PUMA CATch up

Html - PUMA CATch up

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

p : 65 | c : 3 <strong>PUMA</strong>.SAfe<br />

For the first time ever in <strong>PUMA</strong>.Safe operations,<br />

the majority of our social monitoring<br />

activities focused<br />

on factories of<br />

<strong>PUMA</strong> licensees.<br />

Across all tiers<br />

and sourcing<br />

partners, 62 percent<br />

of all audited<br />

facilities globally<br />

were rated A or<br />

B+ while 16 per-<br />

B+ rating.<br />

cent of currently<br />

active facilities<br />

achieved C or D<br />

ratings and thus<br />

failed our audits.<br />

<strong>PUMA</strong> terminated its partnership with 29<br />

Tier1 facilities for non-compliance found<br />

in 2012. Forty-one facilities were assessed<br />

recurrently in line with our monitoring and<br />

remediation policies for facilities rated B-<br />

or lower. In 12 percent of these we found<br />

worse conditions during our follow-<strong>up</strong> visits<br />

despite our remediation efforts. Conditions<br />

in the other factories had improved.<br />

In 2015,<br />

90 percent of our<br />

s<strong>up</strong>pliers will<br />

achieve an A or<br />

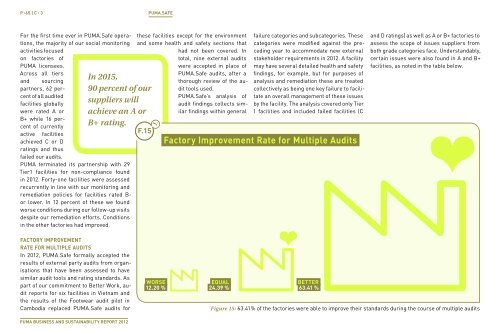

facTory improvemenT<br />

raTe for mulTiple audiTs<br />

In 2012, <strong>PUMA</strong>.Safe formally accepted the<br />

results of external party audits from organisations<br />

that have been assessed to have<br />

similar audit tools and rating standards. As<br />

part of our commitment to Better Work, audit<br />

reports for six facilities in Vietnam and<br />

the results of the Footwear audit pilot in<br />

Cambodia replaced <strong>PUMA</strong>.Safe audits for<br />

<strong>PUMA</strong> BUSineSS And SUStAinABility RePoRt 2012<br />

these facilities except for the environment<br />

and some health and safety sections that<br />

had not been covered. In<br />

total, nine external audits<br />

were accepted in place of<br />

<strong>PUMA</strong>.Safe audits, after a<br />

thorough review of the audit<br />

tools used.<br />

<strong>PUMA</strong>.Safe’s analysis of<br />

audit findings collects similar<br />

findings within general<br />

f.15<br />

t.1<br />

worse.<br />

12.20 %.<br />

eQual.<br />

24.39 %.<br />

failure categories and subcategories. These<br />

categories were modified against the preceding<br />

year to accommodate new external<br />

stakeholder requirements in 2012. A facility<br />

may have several detailed health and safety<br />

findings, for example, but for purposes of<br />

analysis and remediation these are treated<br />

collectively as being one key failure to facilitate<br />

an overall management of these issues<br />

by the facility. The analysis covered only Tier<br />

1 facilities and included failed facilities (C<br />

factory improvement rate for multiple audits<br />

BeTTer.<br />

63.41 %.<br />

and D ratings) as well as A or B+ factories to<br />

assess the scope of issues s<strong>up</strong>pliers from<br />

both grade categories face. Understandably,<br />

certain issues were also found in A and B+<br />

facilities, as noted in the table below.<br />

Figure 15: 63.41 % of the factories were able to improve their standards during the course of multiple audits