A Case Study in NASA-DoD - The Black Vault

A Case Study in NASA-DoD - The Black Vault

A Case Study in NASA-DoD - The Black Vault

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

-153-<br />

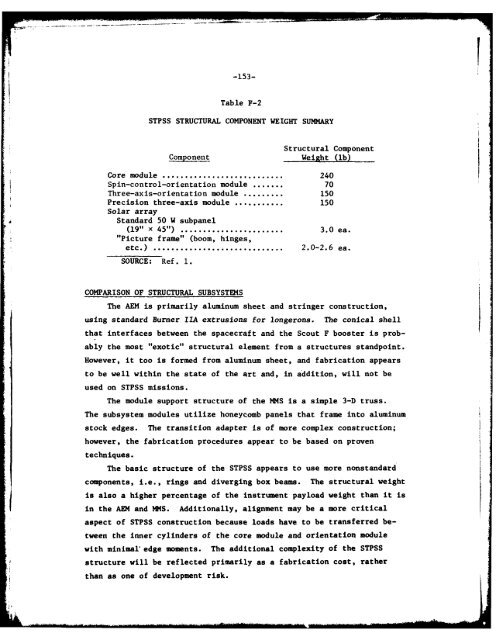

Table F-2<br />

STPSS STRUCTURAL COMPONENT WEIGHT SUMMARY<br />

Component<br />

Structural Component<br />

Weight (lb)<br />

Core module ........................... 240<br />

Sp<strong>in</strong>-control-orientation module ....... 70<br />

Three-axis-orientation module ......... 150<br />

Precision three-axis module ........... 150<br />

Solar array<br />

Standard 50 W subpanel<br />

(19" x 45") ....................... 3.0 ea.<br />

"Picture frame" (boom, h<strong>in</strong>ges,<br />

etc.) ............................. 2.0-2.6 ea.<br />

SOURCE: Ref. 1.<br />

COMPARISON OF STRUCTURAL SUBSYSTEMS<br />

<strong>The</strong> AEM is primarily alum<strong>in</strong>um sheet and str<strong>in</strong>ger construction,<br />

us<strong>in</strong>g standard Burner IIA extrusions for longerons. <strong>The</strong> conical shell<br />

that <strong>in</strong>terfaces between the spacecraft and the Scout F booster is probably<br />

the most "exotic" structural element from a structures standpo<strong>in</strong>t.<br />

However, it too is formed from alum<strong>in</strong>um sheet, and fabrication appears<br />

to be well with<strong>in</strong> the state of the art and, <strong>in</strong> addition, will not be<br />

used on STPSS missions.<br />

<strong>The</strong> module support structure of the MS is a simple 3-D truss.<br />

<strong>The</strong> subsystem modules utilize honeycomb panels that frame <strong>in</strong>to alum<strong>in</strong>um<br />

stock edges. <strong>The</strong> transition adapter is of more complex construction;<br />

however, the fabrication procedures appear to be based on proven<br />

techniques.<br />

<strong>The</strong> basic structure of the STPSS appears to use more nonstandard<br />

components, i.e., r<strong>in</strong>gs and diverg<strong>in</strong>g box beams. <strong>The</strong> structural weight<br />

is also a higher percentage of the <strong>in</strong>strument payload weight than it is<br />

<strong>in</strong> the AEM and M*S. Additionally, alignment may be a more critical<br />

aspect of STPSS construction because loads have to be transferred between<br />

the <strong>in</strong>ner cyl<strong>in</strong>ders of the core module and orientation module<br />

with m<strong>in</strong>imal'edge moments. <strong>The</strong> additional complexity of the STPSS<br />

structure will be reflected primarily as a fabrication cost, rather<br />

than as one of development risk.