standard operating procedure college station fire department

standard operating procedure college station fire department

standard operating procedure college station fire department

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

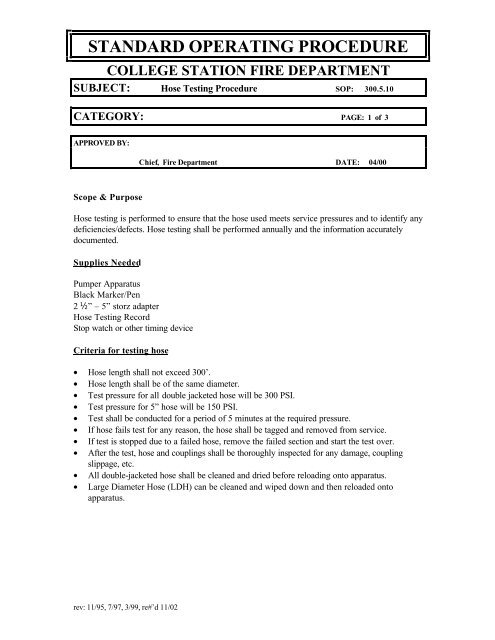

STANDARD OPERATING PROCEDURE<br />

COLLEGE STATION FIRE DEPARTMENT<br />

SUBJECT: Hose Testing Procedure SOP: 300.5.10<br />

CATEGORY: PAGE: 1 of 3<br />

APPROVED BY:<br />

Chief, Fire Department DATE: 04/00<br />

Scope & Purpose<br />

Hose testing is performed to ensure that the hose used meets service pressures and to identify any<br />

deficiencies/defects. Hose testing shall be performed annually and the information accurately<br />

documented.<br />

Supplies Needed<br />

Pumper Apparatus<br />

Black Marker/Pen<br />

2 ½” – 5” storz adapter<br />

Hose Testing Record<br />

Stop watch or other timing device<br />

Criteria for testing hose<br />

• Hose length shall not exceed 300’.<br />

• Hose length shall be of the same diameter.<br />

• Test pressure for all double jacketed hose will be 300 PSI.<br />

• Test pressure for 5” hose will be 150 PSI.<br />

• Test shall be conducted for a period of 5 minutes at the required pressure.<br />

• If hose fails test for any reason, the hose shall be tagged and removed from service.<br />

• If test is stopped due to a failed hose, remove the failed section and start the test over.<br />

• After the test, hose and couplings shall be thoroughly inspected for any damage, coupling<br />

slippage, etc.<br />

• All double-jacketed hose shall be cleaned and dried before reloading onto apparatus.<br />

• Large Diameter Hose (LDH) can be cleaned and wiped down and then reloaded onto<br />

apparatus.<br />

rev: 11/95, 7/97, 3/99, re#’d 11/02