standard operating procedure college station fire department

standard operating procedure college station fire department

standard operating procedure college station fire department

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

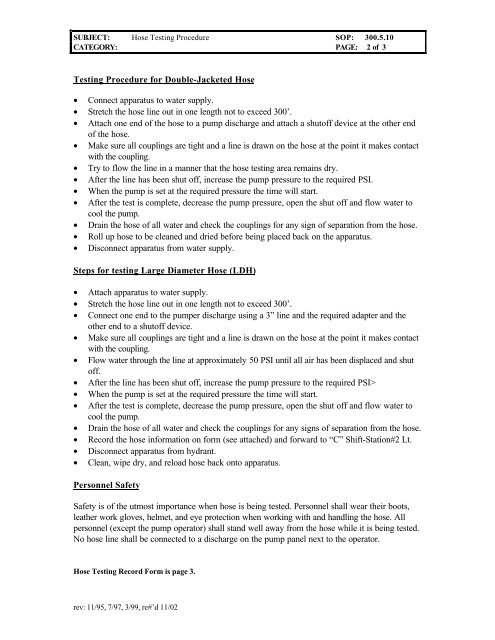

SUBJECT: Hose Testing Procedure SOP: 300.5.10<br />

CATEGORY: PAGE: 2 of 3<br />

Testing Procedure for Double-Jacketed Hose<br />

• Connect apparatus to water supply.<br />

• Stretch the hose line out in one length not to exceed 300’.<br />

• Attach one end of the hose to a pump discharge and attach a shutoff device at the other end<br />

of the hose.<br />

• Make sure all couplings are tight and a line is drawn on the hose at the point it makes contact<br />

with the coupling.<br />

• Try to flow the line in a manner that the hose testing area remains dry.<br />

• After the line has been shut off, increase the pump pressure to the required PSI.<br />

• When the pump is set at the required pressure the time will start.<br />

• After the test is complete, decrease the pump pressure, open the shut off and flow water to<br />

cool the pump.<br />

• Drain the hose of all water and check the couplings for any sign of separation from the hose.<br />

• Roll up hose to be cleaned and dried before being placed back on the apparatus.<br />

• Disconnect apparatus from water supply.<br />

Steps for testing Large Diameter Hose (LDH)<br />

• Attach apparatus to water supply.<br />

• Stretch the hose line out in one length not to exceed 300’.<br />

• Connect one end to the pumper discharge using a 3” line and the required adapter and the<br />

other end to a shutoff device.<br />

• Make sure all couplings are tight and a line is drawn on the hose at the point it makes contact<br />

with the coupling.<br />

• Flow water through the line at approximately 50 PSI until all air has been displaced and shut<br />

off.<br />

• After the line has been shut off, increase the pump pressure to the required PSI><br />

• When the pump is set at the required pressure the time will start.<br />

• After the test is complete, decrease the pump pressure, open the shut off and flow water to<br />

cool the pump.<br />

• Drain the hose of all water and check the couplings for any signs of separation from the hose.<br />

• Record the hose information on form (see attached) and forward to “C” Shift-Station#2 Lt.<br />

• Disconnect apparatus from hydrant.<br />

• Clean, wipe dry, and reload hose back onto apparatus.<br />

Personnel Safety<br />

Safety is of the utmost importance when hose is being tested. Personnel shall wear their boots,<br />

leather work gloves, helmet, and eye protection when working with and handling the hose. All<br />

personnel (except the pump operator) shall stand well away from the hose while it is being tested.<br />

No hose line shall be connected to a discharge on the pump panel next to the operator.<br />

Hose Testing Record Form is page 3.<br />

rev: 11/95, 7/97, 3/99, re#’d 11/02