Quantitative structural analyses and numerical modelling of ...

Quantitative structural analyses and numerical modelling of ...

Quantitative structural analyses and numerical modelling of ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

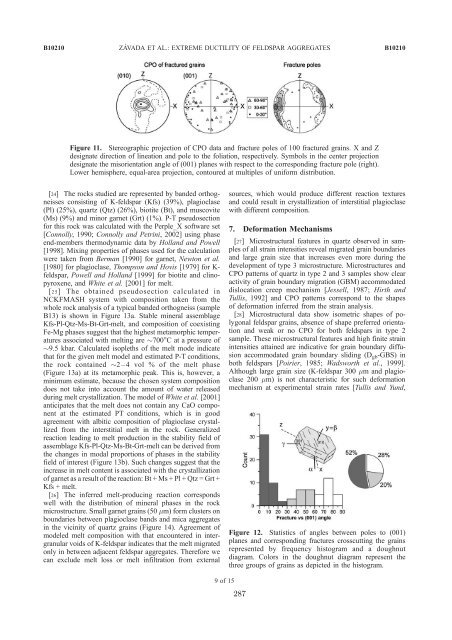

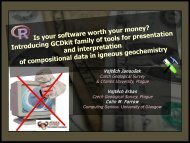

B10210ZÁVADA ET AL.: EXTREME DUCTILITY OF FELDSPAR AGGREGATESB10210Figure 11. Stereographic projection <strong>of</strong> CPO data <strong>and</strong> fracture poles <strong>of</strong> 100 fractured grains. X <strong>and</strong> Zdesignate direction <strong>of</strong> lineation <strong>and</strong> pole to the foliation, respectively. Symbols in the center projectiondesignate the misorientation angle <strong>of</strong> (001) planes with respect to the corresponding fracture pole (right).Lower hemisphere, equal-area projection, contoured at multiples <strong>of</strong> uniform distribution.[24] The rocks studied are represented by b<strong>and</strong>ed orthogneissesconsisting <strong>of</strong> K-feldspar (Kfs) (39%), plagioclase(Pl) (25%), quartz (Qtz) (26%), biotite (Bt), <strong>and</strong> muscovite(Ms) (9%) <strong>and</strong> minor garnet (Grt) (1%). P-T pseudosectionfor this rock was calculated with the Perple_X s<strong>of</strong>tware set[Connolly, 1990; Connolly <strong>and</strong> Petrini, 2002] using phaseend-members thermodynamic data by Holl<strong>and</strong> <strong>and</strong> Powell[1998]. Mixing properties <strong>of</strong> phases used for the calculationwere taken from Berman [1990] for garnet, Newton et al.[1980] for plagioclase, Thompson <strong>and</strong> Hovis [1979] for K-feldspar, Powell <strong>and</strong> Holl<strong>and</strong> [1999] for biotite <strong>and</strong> clinopyroxene,<strong>and</strong> White et al. [2001] for melt.[25] The obtained pseudosection calculated inNCKFMASH system with composition taken from thewhole rock analysis <strong>of</strong> a typical b<strong>and</strong>ed orthogneiss (sampleB13) is shown in Figure 13a. Stable mineral assemblageKfs-Pl-Qtz-Ms-Bt-Grt-melt, <strong>and</strong> composition <strong>of</strong> coexistingFe-Mg phases suggest that the highest metamorphic temperaturesassociated with melting are 700°C at a pressure <strong>of</strong>9.5 kbar. Calculated isopleths <strong>of</strong> the melt mode indicatethat for the given melt model <strong>and</strong> estimated P-T conditions,the rock contained 2–4 vol % <strong>of</strong> the melt phase(Figure 13a) at its metamorphic peak. This is, however, aminimum estimate, because the chosen system compositiondoes not take into account the amount <strong>of</strong> water releasedduring melt crystallization. The model <strong>of</strong> White et al. [2001]anticipates that the melt does not contain any CaO componentat the estimated PT conditions, which is in goodagreement with albitic composition <strong>of</strong> plagioclase crystallizedfrom the interstitial melt in the rock. Generalizedreaction leading to melt production in the stability field <strong>of</strong>assemblage Kfs-Pl-Qtz-Ms-Bt-Grt-melt can be derived fromthe changes in modal proportions <strong>of</strong> phases in the stabilityfield <strong>of</strong> interest (Figure 13b). Such changes suggest that theincrease in melt content is associated with the crystallization<strong>of</strong> garnet as a result <strong>of</strong> the reaction: Bt + Ms + Pl + Qtz = Grt +Kfs + melt.[26] The inferred melt-producing reaction correspondswell with the distribution <strong>of</strong> mineral phases in the rockmicrostructure. Small garnet grains (50 mm) form clusters onboundaries between plagioclase b<strong>and</strong>s <strong>and</strong> mica aggregatesin the vicinity <strong>of</strong> quartz grains (Figure 14). Agreement <strong>of</strong>modeled melt composition with that encountered in intergranularvoids <strong>of</strong> K-feldspar indicates that the melt migratedonly in between adjacent feldspar aggregates. Therefore wecan exclude melt loss or melt infiltration from externalsources, which would produce different reaction textures<strong>and</strong> could result in crystallization <strong>of</strong> interstitial plagioclasewith different composition.7. Deformation Mechanisms[27] Micro<strong>structural</strong> features in quartz observed in samples<strong>of</strong> all strain intensities reveal migrated grain boundaries<strong>and</strong> large grain size that increases even more during thedevelopment <strong>of</strong> type 3 microstructure. Microstructures <strong>and</strong>CPO patterns <strong>of</strong> quartz in type 2 <strong>and</strong> 3 samples show clearactivity <strong>of</strong> grain boundary migration (GBM) accommodateddislocation creep mechanism [Jessell, 1987; Hirth <strong>and</strong>Tullis, 1992] <strong>and</strong> CPO patterns correspond to the shapes<strong>of</strong> deformation inferred from the strain analysis.[28] Micro<strong>structural</strong> data show isometric shapes <strong>of</strong> polygonalfeldspar grains, absence <strong>of</strong> shape preferred orientation<strong>and</strong> weak or no CPO for both feldspars in type 2sample. These micro<strong>structural</strong> features <strong>and</strong> high finite strainintensities attained are indicative for grain boundary diffusionaccommodated grain boundary sliding (D gb -GBS) inboth feldspars [Poirier, 1985; Wadsworth et al., 1999].Although large grain size (K-feldspar 300 mm <strong>and</strong> plagioclase200 mm) is not characteristic for such deformationmechanism at experimental strain rates [Tullis <strong>and</strong> Yund,Figure 12. Statistics <strong>of</strong> angles between poles to (001)planes <strong>and</strong> corresponding fractures crosscutting the grainsrepresented by frequency histogram <strong>and</strong> a doughnutdiagram. Colors in the doughnut diagram represent thethree groups <strong>of</strong> grains as depicted in the histogram.9<strong>of</strong>15287