Hydro Annual Report 2011b

Hydro Annual Report 2011b

Hydro Annual Report 2011b

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

• Using viable energy sources<br />

• Reducing energy consumption and emissions in production<br />

• Reducing CO 2 emissions through the use of our products<br />

• Increasing the recycling of aluminium<br />

<strong>Hydro</strong>’s greenhouse gas emissions from our current consolidated<br />

activities decreased by 5 percent in 2011 compared with 2010.<br />

following Qatalum coming into full production, total emissions<br />

from our ownership equity, including emissions from electricity<br />

generation, increased by 10 percent. Due to our new assets in<br />

Brazil, our direct greenhouse-gas emissions from consolidated<br />

activities increased by 4.5 million metric tons (mt) compared to<br />

the figures reported in <strong>Hydro</strong>’s board report in 2010.<br />

In 2009, we revised our goal to a specific direct emission from<br />

primary production of 1.52 mt CO2e per mt aluminium in<br />

2013. With performance of 1.61 mt CO2e per mt aluminium<br />

last year, we are approaching this target.<br />

Our ambition is to grow faster than the market in recycling and<br />

to take a strong position in this part of the value chain. By 2020,<br />

we aim to recover 1 million metric tons (mt) of contaminated<br />

and post-consumer scrap annually. We have improved utilization<br />

of our existing capacity to almost 100 percent during the<br />

last two years, and are now recycling more than 270,000 mt<br />

annually. Due to curtailments in remelting and recycling capacity,<br />

growth was only about 3 percent compared to 2010. In<br />

total, <strong>Hydro</strong> is remelting and recycling more than 2 million mt<br />

of aluminium. Our goal for 2012 is to stabilize at above 90 percent<br />

capacity utilization and to develop specific post-consumed<br />

scrap projects for investment in additional capacity. This will<br />

also improve <strong>Hydro</strong>’s carbon footprint.<br />

In addition to our existing climate strategy and recycling strategy,<br />

we decided in 2011 to concentrate on four areas going<br />

forward:<br />

• Ecosystems and biodiversity<br />

• Product stewardship<br />

• Waste and efficient resource use<br />

• Emissions<br />

When bauxite extraction is finished in an area, rehabilitation<br />

starts. <strong>Hydro</strong>’s Paragominas mine started production in 2006 and<br />

the reforestation program started in 2009. We have identified<br />

improvement potentials with regards to reforestation and wildlife<br />

management at Paragominas, and are evaluating possible adjustments.<br />

In total 853 hectares of land was disturbed during 2011<br />

and about 4,700 hectares since the mining operations started. In<br />

2011 we rehabilitated 142 hectares, while approximately 400 hectares<br />

have been rehabilitated in total since the operations started.<br />

Enough and clean water is a challenge in some of the areas<br />

where <strong>Hydro</strong> operates. Local initiatives show that with simple<br />

measures, substantial water savings are achievable. Systematic<br />

mapping of our water situation in 2011 showed that in total,<br />

BoArD oF DIreCtors’ report<br />

Environment<br />

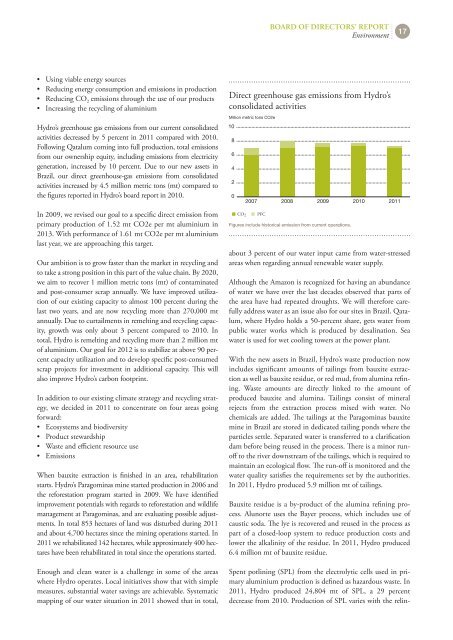

Direct greenhouse gas emissions from <strong>Hydro</strong>’s<br />

consolidated activities<br />

Million metric tons CO2e<br />

10<br />

8<br />

6<br />

4<br />

2<br />

0<br />

CO2<br />

2007<br />

PFC<br />

2008<br />

2009<br />

Figures include historical emission from current operations.<br />

2010<br />

2011<br />

17<br />

about 3 percent of our water input came from water-stressed<br />

areas when regarding annual renewable water supply.<br />

Although the Amazon is recognized for having an abundance<br />

of water we have over the last decades observed that parts of<br />

the area have had repeated droughts. We will therefore carefully<br />

address water as an issue also for our sites in Brazil. Qatalum,<br />

where <strong>Hydro</strong> holds a 50-percent share, gets water from<br />

public water works which is produced by desalination. Sea<br />

water is used for wet cooling towers at the power plant.<br />

With the new assets in Brazil, <strong>Hydro</strong>’s waste production now<br />

includes significant amounts of tailings from bauxite extraction<br />

as well as bauxite residue, or red mud, from alumina refining.<br />

Waste amounts are directly linked to the amount of<br />

produced bauxite and alumina. Tailings consist of mineral<br />

rejects from the extraction process mixed with water. No<br />

chemicals are added. The tailings at the Paragominas bauxite<br />

mine in Brazil are stored in dedicated tailing ponds where the<br />

particles settle. Separated water is transferred to a clarification<br />

dam before being reused in the process. There is a minor runoff<br />

to the river downstream of the tailings, which is required to<br />

maintain an ecological flow. The run-off is monitored and the<br />

water quality satisfies the requirements set by the authorities.<br />

In 2011, <strong>Hydro</strong> produced 5.9 million mt of tailings.<br />

Bauxite residue is a by-product of the alumina refining process.<br />

Alunorte uses the Bayer process, which includes use of<br />

caustic soda. The lye is recovered and reused in the process as<br />

part of a closed-loop system to reduce production costs and<br />

lower the alkalinity of the residue. In 2011, <strong>Hydro</strong> produced<br />

6.4 million mt of bauxite residue.<br />

Spent potlining (SPL) from the electrolytic cells used in primary<br />

aluminium production is defined as hazardous waste. In<br />

2011, <strong>Hydro</strong> produced 24,804 mt of SPL, a 29 percent<br />

decrease from 2010. Production of SPL varies with the relin-