Hydro Annual Report 2011b

Hydro Annual Report 2011b

Hydro Annual Report 2011b

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

The Qatalum aluminium plant, in which we own 50 percent,<br />

came into full production in September 2011. The plant uses<br />

natural gas as its energy source. The International Energy<br />

Agency recognizes natural gas as an important energy source<br />

that can help reduce global temperature increases. In addition,<br />

the use of natural gas in Qatalum is an efficient way of utilizing<br />

local energy sources. In Brazil and Australia, we use power<br />

from the grid. The grid in Brazil is mainly supplied by hydropower,<br />

while the grid in Australia is mainly supplied by coal<br />

power. At Alunorte and Paragominas in Brazil, the main<br />

energy sources are fuel oil, coke and diesel.<br />

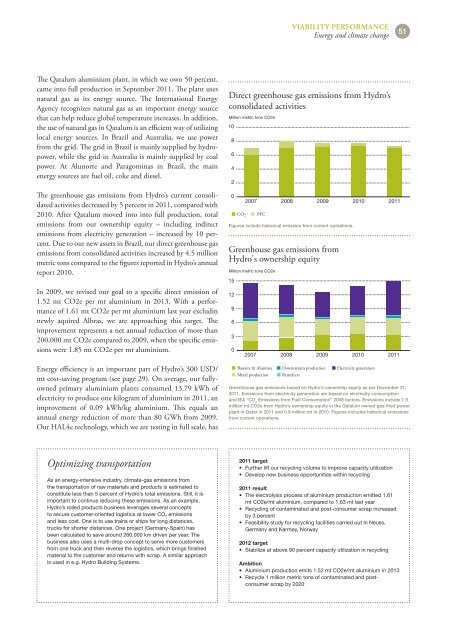

The greenhouse gas emissions from <strong>Hydro</strong>’s current consolidated<br />

activities decreased by 5 percent in 2011, compared with<br />

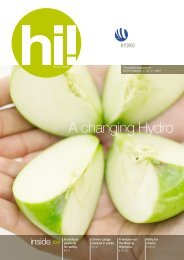

2010. After Qatalum moved into into full production, total<br />

emissions from our ownership equity – including indirect<br />

emissions from electricity generation – increased by 10 percent.<br />

Due to our new assets in Brazil, our direct greenhouse gas<br />

emissions from consolidated activities increased by 4.5 million<br />

metric tons compared to the figures reported in <strong>Hydro</strong>’s annual<br />

report 2010.<br />

In 2009, we revised our goal to a specific direct emission of<br />

1.52 mt CO2e per mt aluminium in 2013. With a performance<br />

of 1.61 mt CO2e per mt aluminium last year excludin<br />

newly aquired Albras, we are approaching this target. The<br />

improvement represents a net annual reduction of more than<br />

200,000 mt CO2e compared to 2009, when the specific emissions<br />

were 1.85 mt CO2e per mt aluminium.<br />

Energy efficiency is an important part of <strong>Hydro</strong>’s 300 USD/<br />

mt cost-saving program (see page 29). On average, our fullyowned<br />

primary aluminium plants consumed 13.79 kWh of<br />

electricity to produce one kilogram of aluminium in 2011, an<br />

improvement of 0.09 kWh/kg aluminium. This equals an<br />

annual energy reduction of more than 80 GWh from 2009.<br />

Our HAL4e technology, which we are testing in full scale, has<br />

Optimizing transportation<br />

As an energy-intensive industry, climate-gas emissions from<br />

the transportation of raw materials and products is estimated to<br />

constitute less than 5 percent of <strong>Hydro</strong>’s total emissions. Still, it is<br />

important to continue reducing these emissions. As an example,<br />

<strong>Hydro</strong>’s rolled products business leverages several concepts<br />

to secure customer-oriented logistics at lower CO 2 emissions<br />

and less cost. One is to use trains or ships for long distances,<br />

trucks for shorter distances. One project (Germany-Spain) has<br />

been calculated to save around 260,000 km driven per year. The<br />

business also uses a multi-drop concept to serve more customers<br />

from one truck and then reverse the logistics, which brings finished<br />

material to the customer and returns with scrap. A similar approach<br />

is used in e.g. <strong>Hydro</strong> Building Systems.<br />

Direct greenhouse gas emissions from <strong>Hydro</strong>’s<br />

consolidated activities<br />

Million metric tons CO2e<br />

10<br />

8<br />

6<br />

4<br />

2<br />

0<br />

CO2<br />

2007<br />

PFC<br />

2008<br />

2009<br />

Greenhouse gas emissions from<br />

<strong>Hydro</strong>'s ownership equity<br />

Million metric tons CO2e<br />

15<br />

12<br />

9<br />

6<br />

3<br />

0<br />

2007<br />

2008<br />

vIABIlItY perForMAnCe<br />

Energy and climate change<br />

Figures include historical emission from current operations.<br />

2009<br />

2010<br />

2010<br />

Bauxite & Alumina Downstream production Electricity generation<br />

Metal production Remelters<br />

2011 target<br />

• Further lift our recycling volume to improve capacity utilization<br />

• Develop new business opportunities within recycling<br />

2011 result<br />

• The electrolysis process of aluminium production emitted 1.61<br />

mt CO2e/mt aluminium, compared to 1.63 mt last year<br />

• Recycling of contaminated and post-consumer scrap increased<br />

by 3 percent<br />

• Feasibility study for recycling facilities carried out in Neuss,<br />

Germany and Karmøy, Norway<br />

2012 target<br />

• Stabilize at above 90 percent capacity utilization in recycling<br />

2011<br />

2011<br />

Ambition<br />

• Aluminium production emits 1.52 mt CO2e/mt aluminium in 2013<br />

• Recycle 1 million metric tons of contaminated and postconsumer<br />

scrap by 2020<br />

51<br />

Greenhouse gas emissions based on <strong>Hydro</strong>’s ownership equity as per December 31,<br />

2011. Emissions from electricity generation are based on electricity consumption<br />

and IEA “CO 2 Emissions from Fuel Consumption” 2008 factors. Emissions include 1.9<br />

million mt CO2e from <strong>Hydro</strong>’s ownership equity in the Qatalum owned gas-fired power<br />

plant in Qatar in 2011 and 0.9 million mt in 2010. Figures includes historical emissions<br />

from current operations.