Hydro Annual Report 2011b

Hydro Annual Report 2011b

Hydro Annual Report 2011b

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

56<br />

vIABIlItY perForMAnCe<br />

Integrity and human rights<br />

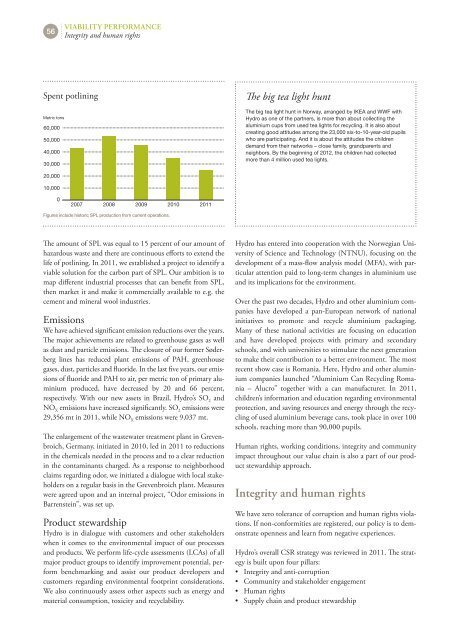

Spent potlining<br />

Metric tons<br />

60,000<br />

50,000<br />

40,000<br />

30,000<br />

20,000<br />

10,000<br />

0<br />

2007<br />

2008<br />

2009<br />

Figures include historic SPL production from current operations.<br />

2010<br />

2011<br />

The amount of SPL was equal to 15 percent of our amount of<br />

hazardous waste and there are continuous efforts to extend the<br />

life of potlining. In 2011, we established a project to identify a<br />

viable solution for the carbon part of SPL. Our ambition is to<br />

map different industrial processes that can benefit from SPL,<br />

then market it and make it commercially available to e.g. the<br />

cement and mineral wool industries.<br />

Emissions<br />

We have achieved significant emission reductions over the years.<br />

The major achievements are related to greenhouse gases as well<br />

as dust and particle emissions. The closure of our former Søderberg<br />

lines has reduced plant emissions of PAH, greenhouse<br />

gases, dust, particles and fluoride. In the last five years, our emissions<br />

of fluoride and PAH to air, per metric ton of primary aluminium<br />

produced, have decreased by 20 and 66 percent,<br />

respectively. With our new assets in Brazil, <strong>Hydro</strong>’s SO 2 and<br />

NO X emissions have increased significantly. SO 2 emissions were<br />

29,356 mt in 2011, while NO X emissions were 9,037 mt.<br />

The enlargement of the wastewater treatment plant in Grevenbroich,<br />

Germany, initiated in 2010, led in 2011 to reductions<br />

in the chemicals needed in the process and to a clear reduction<br />

in the contaminants charged. As a response to neighborhood<br />

claims regarding odor, we initiated a dialogue with local stakeholders<br />

on a regular basis in the Grevenbroich plant. Measures<br />

were agreed upon and an internal project, “Odor emissions in<br />

Barrenstein”, was set up.<br />

Product stewardship<br />

<strong>Hydro</strong> is in dialogue with customers and other stakeholders<br />

when it comes to the environmental impact of our processes<br />

and products. We perform life-cycle assessments (LCAs) of all<br />

major product groups to identify improvement potential, perform<br />

benchmarking and assist our product developers and<br />

customers regarding environmental footprint considerations.<br />

We also continuously assess other aspects such as energy and<br />

material consumption, toxicity and recyclability.<br />

The big tea light hunt<br />

The big tea light hunt in Norway, arranged by IKEA and WWF with<br />

<strong>Hydro</strong> as one of the partners, is more than about collecting the<br />

aluminium cups from used tea lights for recycling. It is also about<br />

creating good attitudes among the 23,000 six-to-10-year-old pupils<br />

who are participating. And it is about the attitudes the children<br />

demand from their networks – close family, grandparents and<br />

neighbors. By the beginning of 2012, the children had collected<br />

more than 4 million used tea lights.<br />

<strong>Hydro</strong> has entered into cooperation with the Norwegian University<br />

of Science and Technology (NTNU), focusing on the<br />

development of a mass-flow analysis model (MfA), with particular<br />

attention paid to long-term changes in aluminium use<br />

and its implications for the environment.<br />

Over the past two decades, <strong>Hydro</strong> and other aluminium companies<br />

have developed a pan-European network of national<br />

initiatives to promote and recycle aluminium packaging.<br />

Many of these national activities are focusing on education<br />

and have developed projects with primary and secondary<br />

schools, and with universities to stimulate the next generation<br />

to make their contribution to a better environment. The most<br />

recent show case is Romania. Here, <strong>Hydro</strong> and other aluminium<br />

companies launched “Aluminium Can Recycling Romania<br />

– Alucro” together with a can manufacturer. In 2011,<br />

children’s information and education regarding environmental<br />

protection, and saving resources and energy through the recycling<br />

of used aluminium beverage cans, took place in over 100<br />

schools, reaching more than 90,000 pupils.<br />

Human rights, working conditions, integrity and community<br />

impact throughout our value chain is also a part of our product<br />

stewardship approach.<br />

Integrity and human rights<br />

We have zero tolerance of corruption and human rights violations.<br />

If non-conformities are registered, our policy is to demonstrate<br />

openness and learn from negative experiences.<br />

<strong>Hydro</strong>’s overall CSR strategy was reviewed in 2011. The strategy<br />

is built upon four pillars:<br />

• Integrity and anti-corruption<br />

• Community and stakeholder engagement<br />

• Human rights<br />

• Supply chain and product stewardship